Quality detection device and method of encapsulation LED solder joint

A technology of solder joint quality and detection device, applied in the direction of optical testing flaws/defects, etc., can solve problems such as product failure, influence of welding quality, and influence of welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

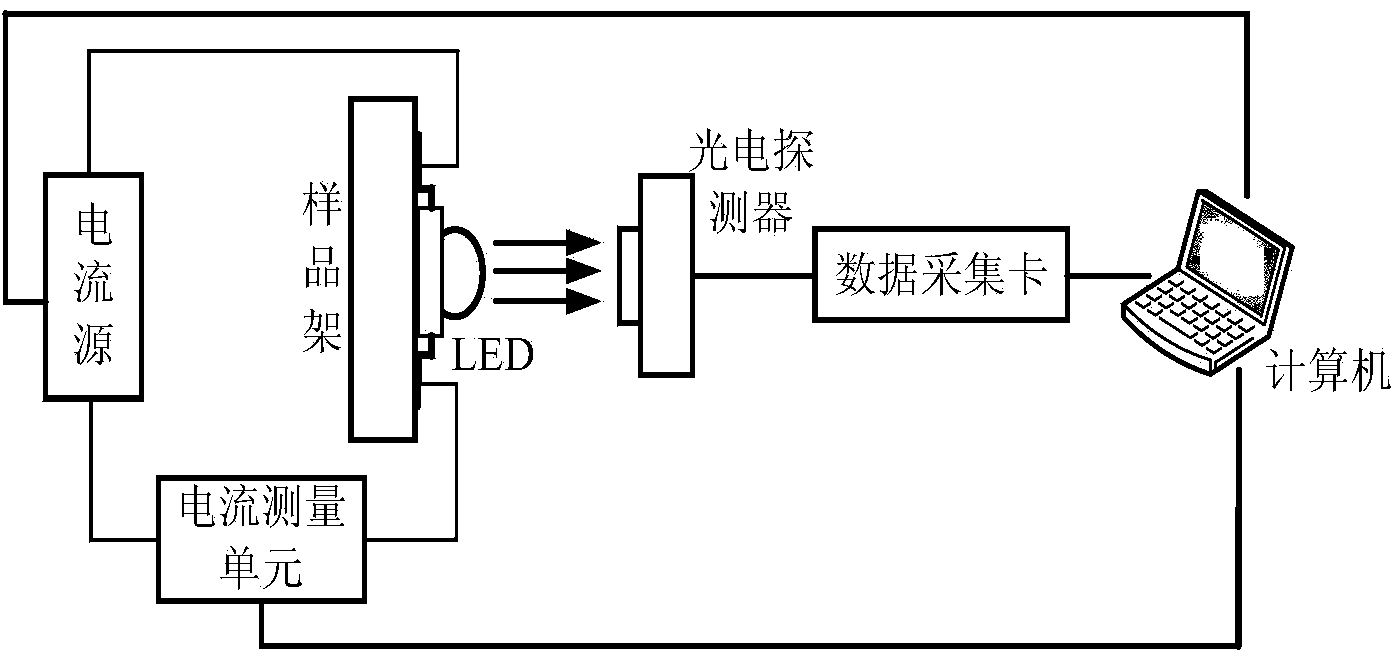

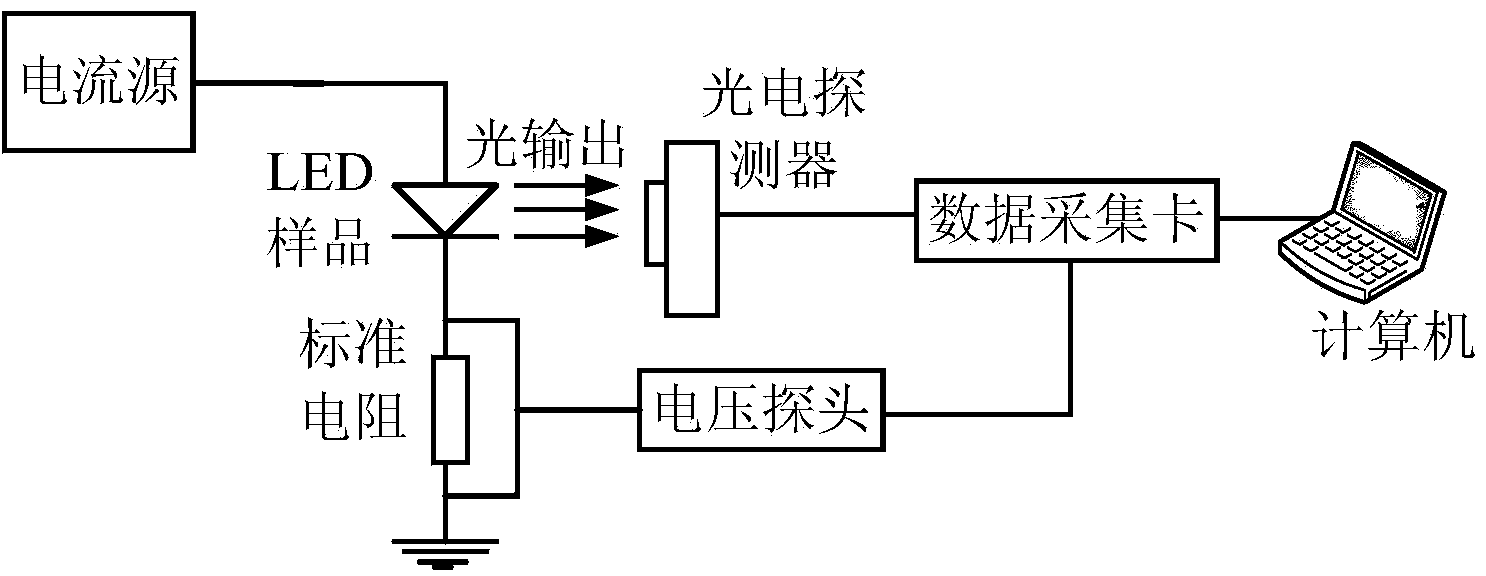

[0044] Such as figure 1As shown, the packaging LED solder joint quality detection device includes a current source, a sample holder, a current measurement unit, a photodetector, a data acquisition card and a computer; the current source drives the LED on the sample holder to work, and the instantaneous current of the LED switch is determined by The current measurement unit is obtained and output to the computer; the photodetector is arranged in front of the sample holder for collecting the light signal sent by the LED and converting the light signal into an electrical signal; the output terminal of the photodetector is connected to the The data acquisition card is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com