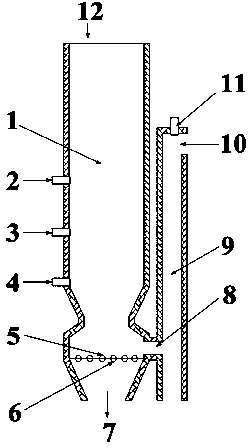

Downdraft gasifier with tar degrading function

A gasification furnace, a functional technology, applied in the field of clean utilization of waste resources, can solve the problems of short residence time, flue blockage, high tar content, etc., and achieve the effect of high quality, simple structure and prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

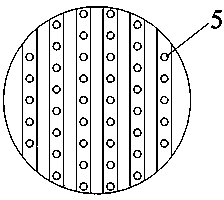

[0011] refer to figure 1 , the downdraft gasifier with tar degradation function of the present invention comprises a hearth 1, the lower part of the hearth has an annular neck, a feed port 12 is arranged at the top of the hearth, an ash outlet 7 is arranged at the bottom, and an annular neck is arranged at the hearth On the furnace wall above, there are upper, middle and lower tangential primary air distribution ports 2, 3 and 4 along the axial direction, and each level has four tangential air distribution ports along the furnace circumference (such as figure 2 example shown), the primary gasification air can be tangentially injected into the furnace from the top, middle and bottom of the furnace wall, forming a swirl area in the furnace, which is conducive to good mixing of the gasification medium and materials, and prolongs the The residence time of materials in the high temperature zone. A tubular grate 6 is placed between the annular constriction at the lower part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com