Process device for treatment of salt coagulation of fractionating column top circulation system

A technology of process equipment and fractionation tower, which is applied in the fields of processing hydrocarbon oil, processing equipment corrosion/fouling suppression, and petroleum industry, and can solve problems such as increased operating severity, impact on downstream devices, and greater impact on the quality of coked diesel products. The effect of preventing salt formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

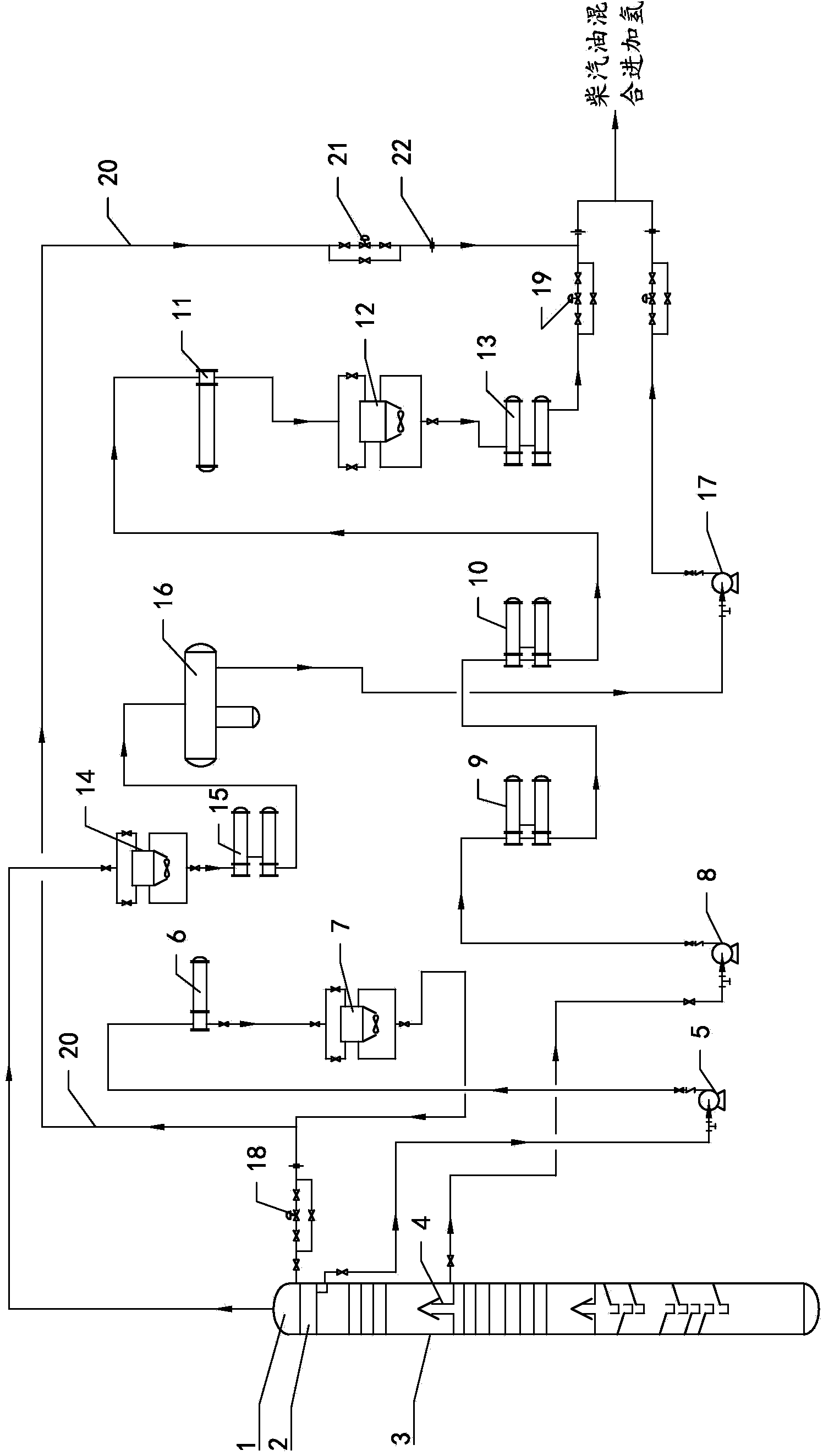

[0025] Combine below figure 1 The present invention will be described in detail with specific embodiments. This patent example selects Shandong Jincheng Petrochemical Group Co., Ltd. 40×10 4 T / a delayed coker.

[0026] Diesel oil is drawn out from fractionation tower oil collecting tank 4 by diesel pump 8, goes to diesel air cooler 12 and cools to After 55°C, go to the diesel oil water cooler 13 to cool down to 40°C, and after the flow is controlled by the regulating valve 19 of the diesel output unit, it is mixed with gasoline and sent to the hydrogenation unit.

[0027] The oil gas at the top of the fractionation tower is cooled to 40°C by the air cooler 14 and the water cooler 15 at the top of the fractionation tower, and then flows into the oil-gas separation tank 16 at the top of the fractionation tower. device.

[0028] The circulating oil at the top of the fractionating tower is extracted from the second tray 2 in the fractionating tower 3 by the circulating reflux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com