Preparation method of environment-friendly light-resistant and waterproof polyurethane coating and adhesive

A technology of polyurethane coating and water resistance, which is applied in the direction of polyurea/polyurethane adhesive, polyurea/polyurethane coating, adhesive type, etc. It can solve the problems of poor quality, large toxic side effects and carcinogenicity, and achieve improved waterproofing High performance, improved light fastness efficiency, waterproof and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

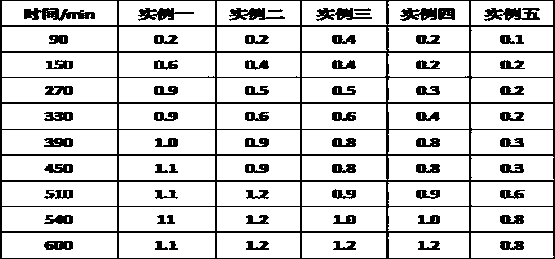

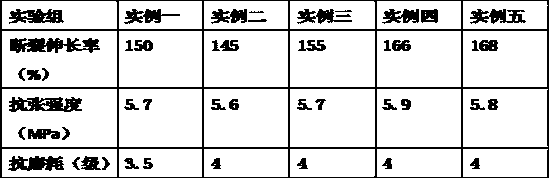

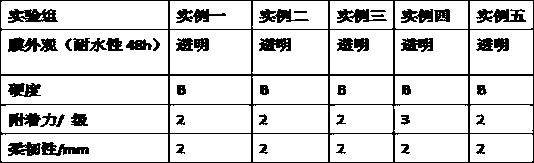

Examples

example 1

[0019] (1) In a 500ml four-necked flask equipped with a stirring blade, a thermometer and a condenser tube, mix 50g of polytetrahydrofuran ether glycol and 33.3g of isophorone diisocyanate in the presence of 0.17g of dibutyltin dilaurate catalyst Under the condition of 80 DEG C, react for 1 h, add 0.08 g of sphingomyelin, react for 1 h, and react at 80 DEG C to obtain 83 g of polyurethane prepolymer A;

[0020] (2) Add 1 g of gallic acid and 10 g of 1,1,2-trifluorotrichloroethane to prepolymer A, react at 65° C. for 1.5 h, add 0.42 g of tetrafluoropropanol, and react at a temperature of 75° C. After 1 hour, 8.3 g of triethylamine was added for neutralization reaction for 30 minutes, and water was added for emulsification to obtain an environmentally friendly light-resistant and waterproof polyurethane coating and adhesive.

example 2

[0022] (1) In a 500ml four-necked flask equipped with a stirring blade, a thermometer, and a condenser tube, mix 50g of polytetrahydrofuran ether glycol and 99.9g of isophorone diisocyanate, in the presence of dibutyltin dilaurate catalyst 0.75 Under the conditions, react at 100°C for 4h, add 0.60g of vincristine sulfate, react for 1h, and react at a temperature of 80°C to obtain 150g of polyurethane prepolymer A;

[0023] (2), 4.8g of epicatechin and 37.5g of 1,1,2-trifluorotrichloroethane added to prepolymer A, reacted at 85°C for 3.5h, added 1.8g of octafluoropentanol, and the reaction temperature 85°C, reaction time 2h, add 22.5g of triethylamine for neutralization reaction for 50min, add water for emulsification, and get environment-friendly lightfast and waterproof polyurethane coating and adhesive.

example 3

[0025] (1) In a 500ml four-necked flask equipped with a stirring blade, a thermometer and a condenser tube, mix 50g of polytetrahydrofuran ether glycol and 66.6g of isophorone diisocyanate in the presence of 0.40g of dibutyltin dilaurate catalyst Under the conditions of 90°C for 2.5h, 0.29g of dihydrosphingomyelin was added, the reaction time was 1h, and the reaction temperature was 80°C to obtain 116g of polyurethane prepolymer A;

[0026] (2) Add 2.6g Lycium barbarum polysaccharide and 20g 1,1,2-trifluorotrichloroethane to prepolymer A, react at 75°C for 2.5h, add 2,3,5,6-tetrafluoro 0.93g of benzyl alcohol, reaction temperature of 80°C, reaction time of 1.5h, adding 14.5g of triethylamine for neutralization reaction for 40min, adding water for emulsification, to obtain environment-friendly lightfast and waterproof polyurethane coating and adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com