Fracturing fluid drag reducer, and preparation method and application thereof

A technology of drag reducing agent and fracturing fluid, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of inability to realize on-site liquid preparation, long dissolution time, etc., and achieve shortened dissolution time and good viscosity increasing effect. , the effect of small dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

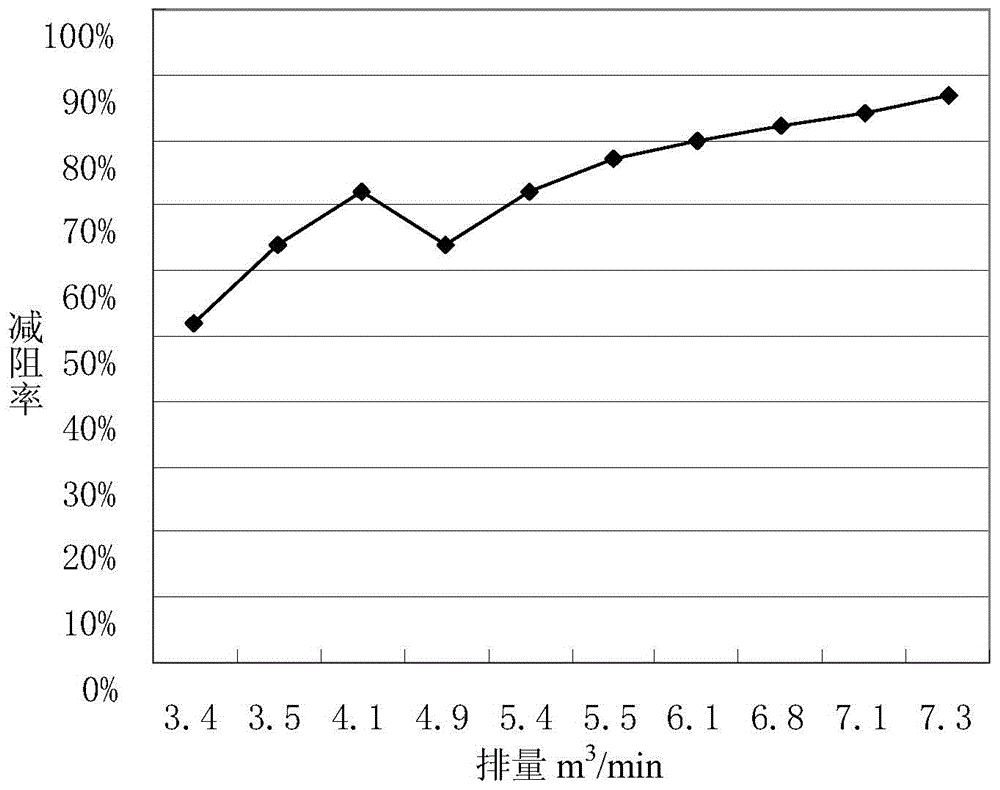

Image

Examples

Embodiment 1

[0045] Components:

[0046] 60g No. 24 white oil, 8g compound emulsifier, 4g co-emulsifier propanol, 10g acrylic acid, 2g2-methyl-2-allyl ammonium chloride, 2g2-acrylamido-2-methylpropanesulfonic acid, 4g Sodium bicarbonate, 20g of acrylamide, 4mL of 1% ammonium persulfate and sodium bisulfite solution, and water were added to a total of 200g.

[0047] Preparation:

[0048] (1) Add No. 24 white oil, compound emulsifier Span-80 and Tween-60 at a ratio of 22:3, and co-emulsifier propanol in a 500mL three-neck flask, stir until fully mixed, and the stirring speed is 1.2m / s (linear speed of the outer ring of the stirring paddle);

[0049] (2) Add water, acrylic acid, 2-methyl-2-allyl ammonium chloride and 2-acrylamido-2-methylpropanesulfonic acid into the beaker, add sodium bicarbonate while stirring, and stir until fully Dissolve, the stirring speed is 1.2m / s (linear speed of the outer ring of the stirring paddle);

[0050] (3) Add acrylamide to the beaker in step (2), stir ...

Embodiment 2

[0054]40g No. 24 white oil, 6g compound emulsifier, 3g co-emulsifier propanol, 20g acrylic acid, 4g2-methyl-2-allyl ammonium chloride, 3g2-acrylamido-2-methylpropanesulfonic acid, 8g Sodium bicarbonate, 30g of acrylamide, 8mL of 1% ammonium persulfate and sodium bisulfite solution, and water were added to a total of 200g.

[0055] (1) Add No. 24 white oil, compound emulsifier Span-80 and Tween-60 at a ratio of 22:3, and co-emulsifier propanol in a 500mL three-neck flask, stir until fully mixed, and the stirring speed is 1.2m / s (linear speed of the outer ring of the stirring paddle);

[0056] (2) Add water, acrylic acid, 2-methyl-2-allyl ammonium chloride and 2-acrylamido-2-methylpropanesulfonic acid into the beaker, add sodium bicarbonate while stirring, and stir until fully Dissolve, the stirring speed is 1.2m / s (the linear speed of the outer ring of the stirring paddle);

[0057] (3) Add acrylamide to the beaker in step (2), stir until fully dissolved, and the stirring sp...

Embodiment 3

[0061] 30g No. 24 white oil, 4g compound emulsifier, 2g co-emulsifier propanol, 30g acrylic acid, 6g 2-methyl-2-allyl ammonium chloride, 4g 2-acrylamido-2-methylpropanesulfonic acid, 12g Sodium bicarbonate, 40g of acrylamide, 14mL of 1% ammonium persulfate and sodium bisulfite solution, and water were added to a total of 200g.

[0062] (1) In a 500mL three-necked flask, add No. 24 white oil, the compound emulsifier is Span-80 and Tween-60 at a ratio of 22:3, and the co-emulsifier propanol, stir until fully mixed, and the stirring speed is 1.2m / s (linear speed of the outer ring of the stirring paddle);

[0063] (2) Add water, acrylic acid, 2-methyl-2-allyl ammonium chloride and 2-acrylamido-2-methylpropanesulfonic acid into the beaker, add sodium bicarbonate while stirring, and stir until fully Dissolve, the stirring speed is 1.2m / s (the linear speed of the outer ring of the stirring paddle);

[0064] (3) Add acrylamide to the beaker in step (2), stir until fully dissolved, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com