A kind of enveloping heating small-scale urea hydrolysis reaction device and hydrolysis method

A technology of urea hydrolysis and reaction device, which is applied in the chemical industry to achieve the effects of good followability, stable system operation and small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

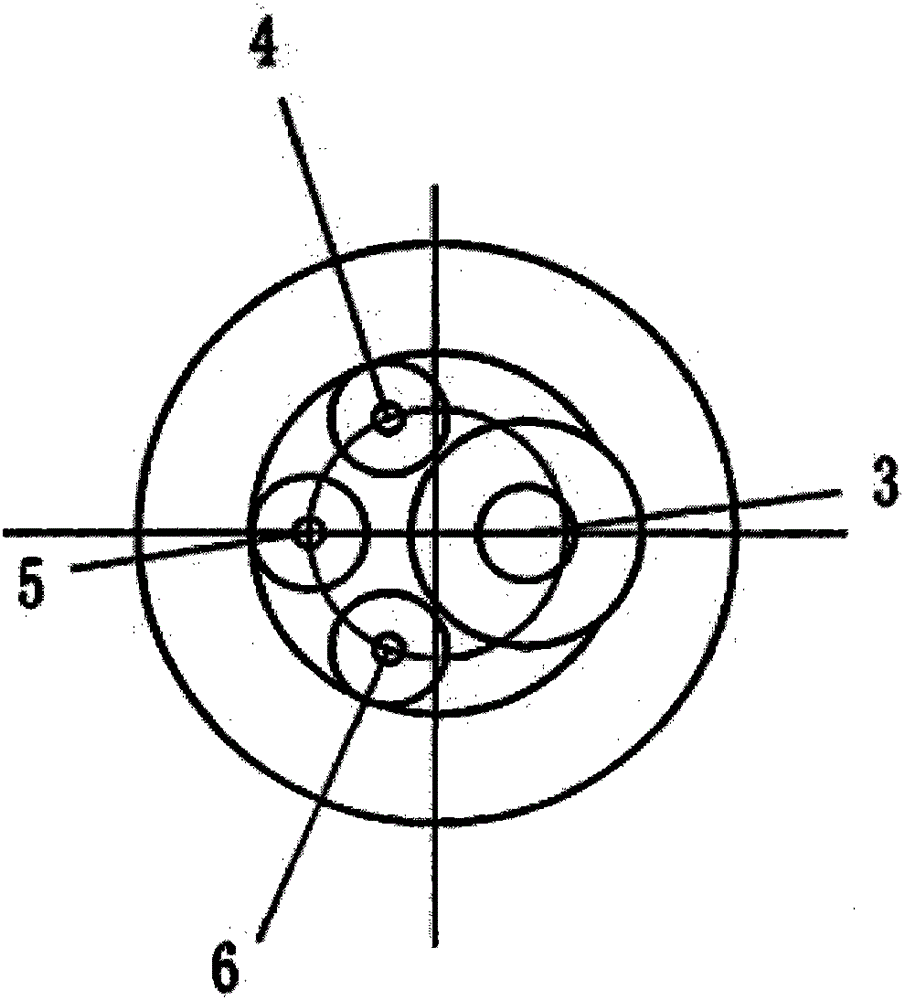

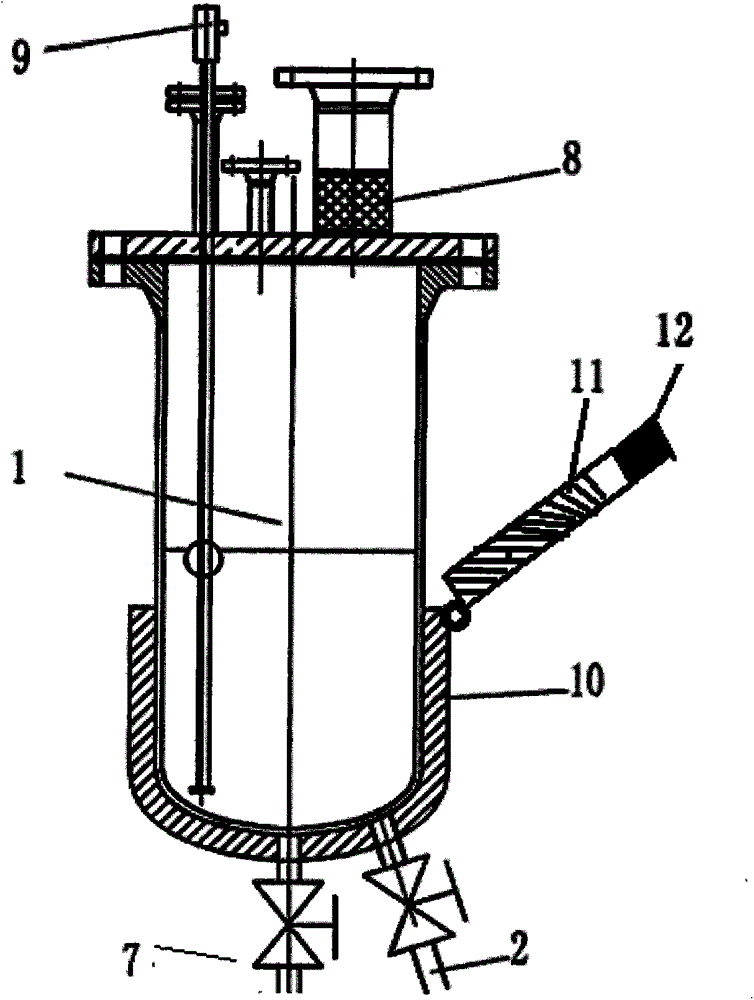

[0024] to combine figure 1 with figure 2 ;

[0025] 1. A small-scale urea hydrolysis reaction device with surrounding heating is characterized in that it comprises a reactor 1, and the bottom of the reactor 1 is surrounded by a heating mantle, and the heating mantle is steam heating or electric heating, and the heating mantle The sleeve fits the reactor 1, the reactor is supported by legs, the upper part of the reactor is provided with a reaction product outlet, and the bottom of the reactor is provided with a urea solution feed port and a sewage discharge port, and the feed port and the sewage discharge port penetrate the bottom of the reactor and Heating jacket; the heat required for urea hydrolysis reaction can be provided by steam heating or electric heating; the inner part of the reactor cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com