Abrasive belt grinding device for crankshaft

A technology of abrasive belt grinding and abrasive belt grinding, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding machines, etc., to achieve the effect of saving complex process and operation skills and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

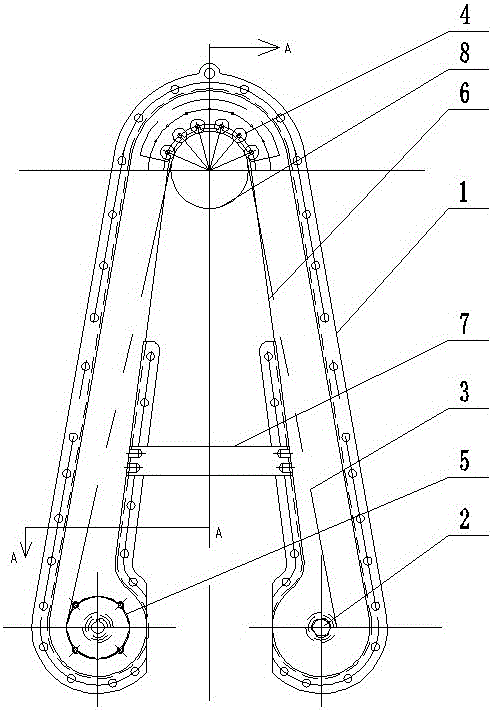

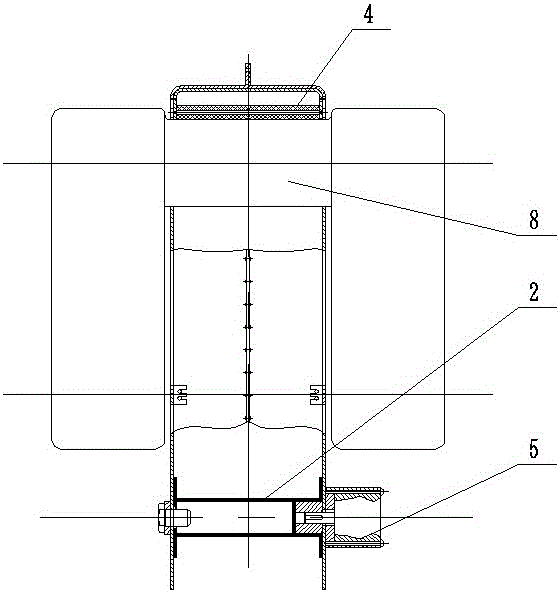

[0023] Such as Figure 1-2 The abrasive belt grinding device for the crankshaft of the present embodiment shown includes an inverted U-shaped housing 1, and an abrasive belt grinder is installed inside the inverted U-shaped housing, and the abrasive belt grinder includes respectively installed in the inverted U-shaped housing. The abrasive belt reels 2 on both sides of the lower part of the U-shaped housing, the abrasive belt 3 is wound on the abrasive belt reels on both sides of the lower part of the inverted U-shaped housing, and each of the The abrasive belt reel is connected with the drive motor 5 .

[0024] The abrasive belt grinding device for the crankshaft has an opening 6 under the upper part of the inverted U-shaped housing, and the abrasive belt passes through the inverted U-shaped housing at the opening, and the pressing wheel is installed Compress the abrasive belt at the opening of the upper part of the inverted U-shaped housing and above the abrasive belt.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com