Preparation method of natural marine compound polypeptide moisturizing agent

A technology of moisturizing agent and compound enzyme preparation, which is applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problem that hydrolase cannot be recycled, achieve a wide range of products, improve transdermal absorption effect, no The effect of three industrial wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

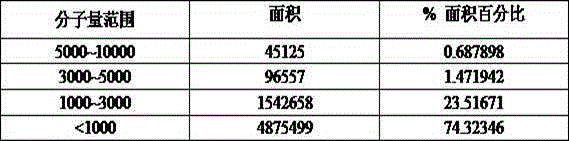

[0026] Preparation of marine animal and plant protein powder: wash, pulverize and enzymolyze the crab scraps (the compound enzyme preparation is alkaline protease and neutral protease, the ratio by weight is 1:0.5. The addition amount of the compound enzyme preparation is 1.5%, hydrolysis The temperature is 40°C, the pH is 6.5, the hydrolysis time is 4h), the centrifugal speed is 3000rpm, the pH is adjusted to 5, filtered, decolorized, and finally spray-dried.

[0027] Weigh 100kg of marine animal and plant protein powder, mix it with 2500kg of 50°C warm water in a reaction kettle, adjust the pH to 6.5, and then add compound protease preparations (alkaline protease, neutral protease, papain, flavor protease (all purchased from Novi Xin (China) Biotechnology Co., Ltd.) with a mass ratio of 1:0.3:0.2:0.2), so that its mass percentage concentration in the solution is 1.5%, hydrolyzed at a temperature of 40 ° C for 4 hours, and then the fixed Decolorization, filtration, and decolo...

Embodiment 2

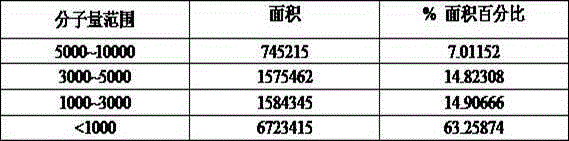

[0035] Preparation of marine animal and plant protein powder: wash, crush and enzymatically hydrolyze the leftovers of crab and fish (mixed according to the mass fraction of 1:1) (the compound enzyme preparation is alkaline protease and neutral protease, and the weight ratio is 1:1 The addition of compound enzyme preparation is 1.5%, the hydrolysis temperature is 40°C, the pH is 6.5, and the hydrolysis time is 4h), centrifuged (speed 4000rpm), adjusted to pH 6, filtered, decolorized, and finally spray-dried.

[0036]Weigh 100kg of marine animal and plant protein powder, mix it with 3000kg of 40°C warm water in a reaction kettle, adjust the pH to 8.0, and then add compound protease preparations (alkaline protease, neutral protease, papain, flavor protease (all purchased from Novi Xin (China) Biotechnology Co., Ltd.) with a mass ratio of 1:0.5:0.1:0.1), so that its mass percentage concentration in the solution is 0.5%, hydrolyzed at a temperature of 40°C for 6 hours, and then the...

Embodiment 3

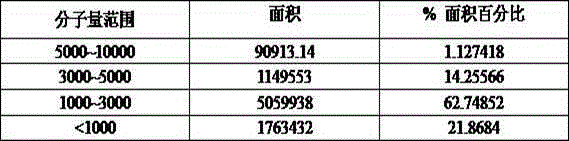

[0044] Preparation of marine animal and plant protein powder: wash, pulverize and enzymatically hydrolyze crab scraps (the compound enzyme preparation is alkaline protease and neutral protease, the ratio by weight is 1:0.8. The addition of compound enzyme preparation is 1.5%, hydrolysis Temperature 40°C, pH 6.5, hydrolysis time 4h), centrifugation (speed 5000rpm), adjust pH to 7, filter, decolorize, and finally spray dry.

[0045] Weigh 100kg of marine animal and plant protein powder, mix it with 4200kg of warm water at 50°C in a reaction kettle, adjust the pH to 7.0, and then add compound protease preparations (alkaline protease, neutral protease, papain, flavor protease (all purchased from Nuo Weixin (China) Biotechnology Co., Ltd.) was compounded at a mass ratio of 1:0.3:0.2:0.2), so that its mass percentage concentration in the solution was 0.5%, hydrolyzed at a temperature of 50°C for 8 hours, and then separated Immobilized enzyme, filtration, decolorization (activated ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com