Electric bicycle hub motor

A technology of electric bicycles and wheel hub motors, which is applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of small output torque, unsightly, complex appearance, etc., and achieve the effect of increasing output torque and large reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

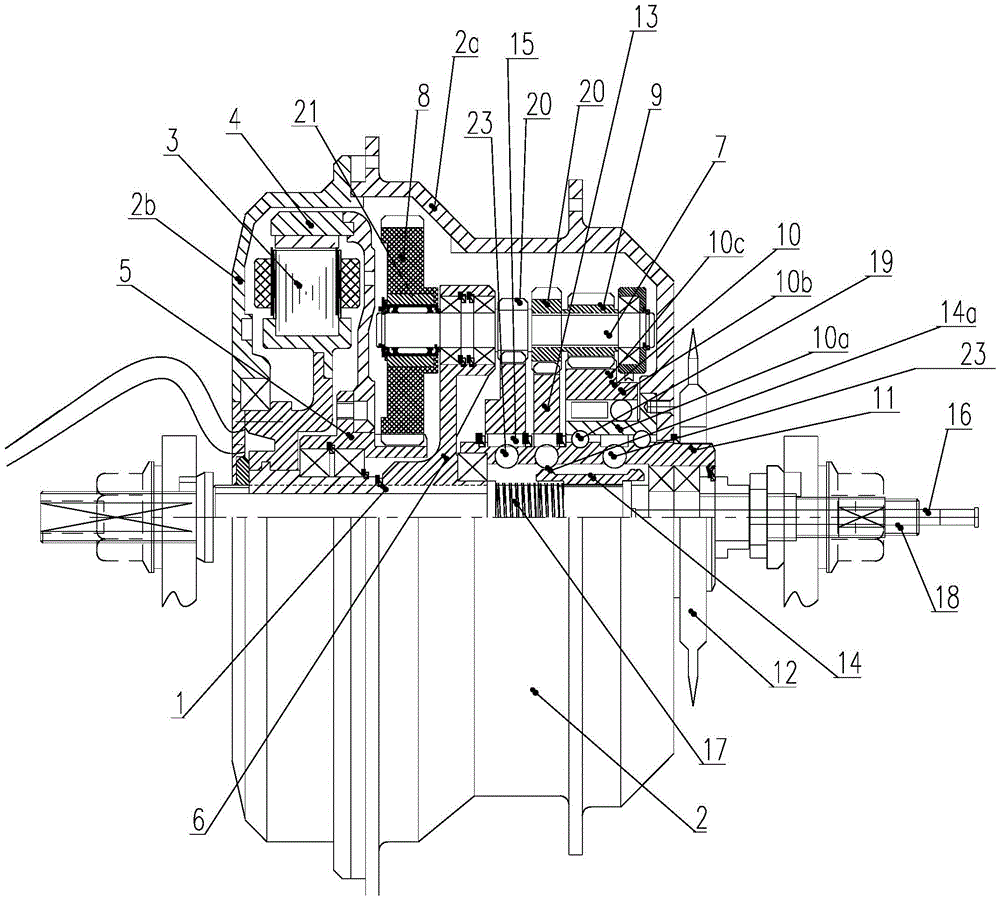

[0025] figure 1 A specific embodiment of the electric bicycle hub motor of the present invention is shown, which includes a horizontally arranged main shaft 1, on which a hub shell 2 that can rotate around the main shaft is installed through a bearing (not marked in the figure), the hub The housing 2 is composed of a housing body 2a and a housing end cover 2b which are fixed to each other. The hub shell 2 is provided with a stator 3, a rotor 4 and a gear reduction mechanism, wherein the stator is fixed on the main shaft 1, and this example adopts an outer rotor inner stator structure.

[0026] The first key improvement point of this embodiment is that the structure of the gear reduction mechanism is completely different from that of the traditional gear reduction mechanism, as follows:

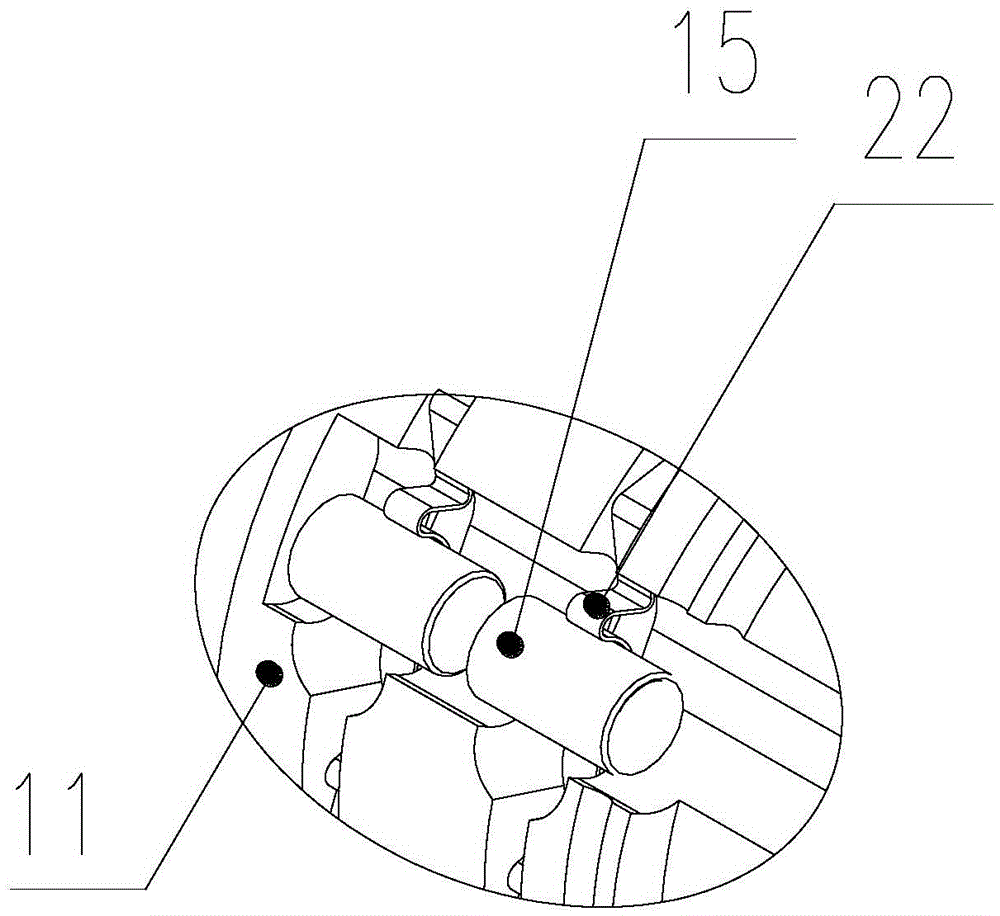

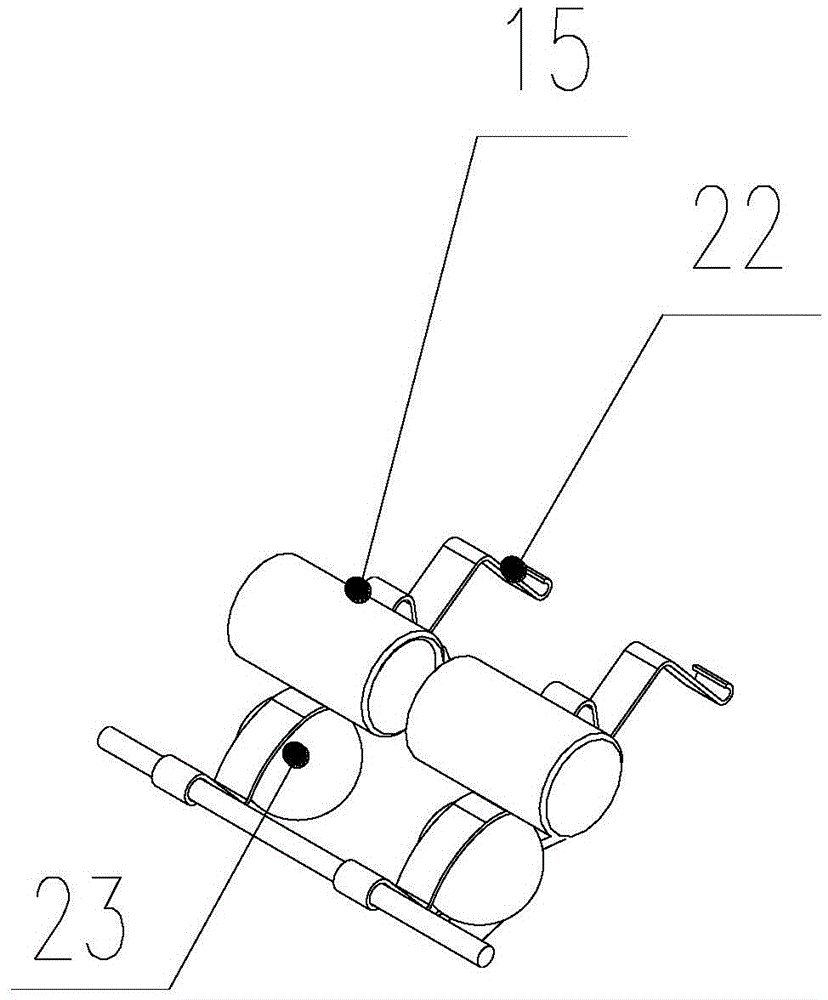

[0027] The gear reduction mechanism in this example is mainly composed of rotor gear 5 , planetary carrier 6 , planetary shaft 7 , left planetary gear 8 , right planetary gear 9 and sun gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com