Lithium ion battery electrolyte solution

A lithium-ion battery, electrolyte technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., can solve the problems of low temperature performance of lithium batteries, and achieve high voltage resistance performance, high thermal decomposition temperature, and electrical conductivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

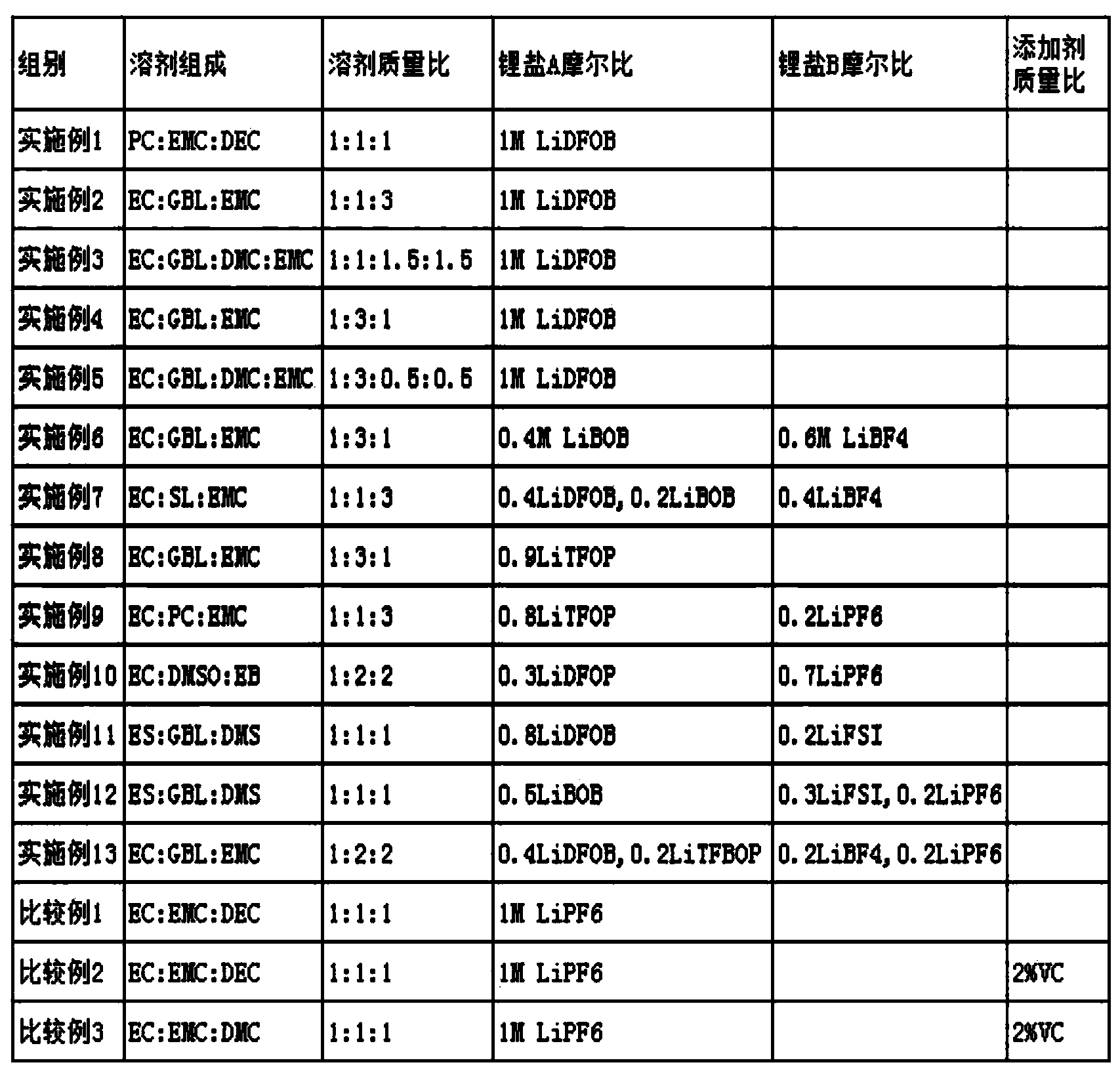

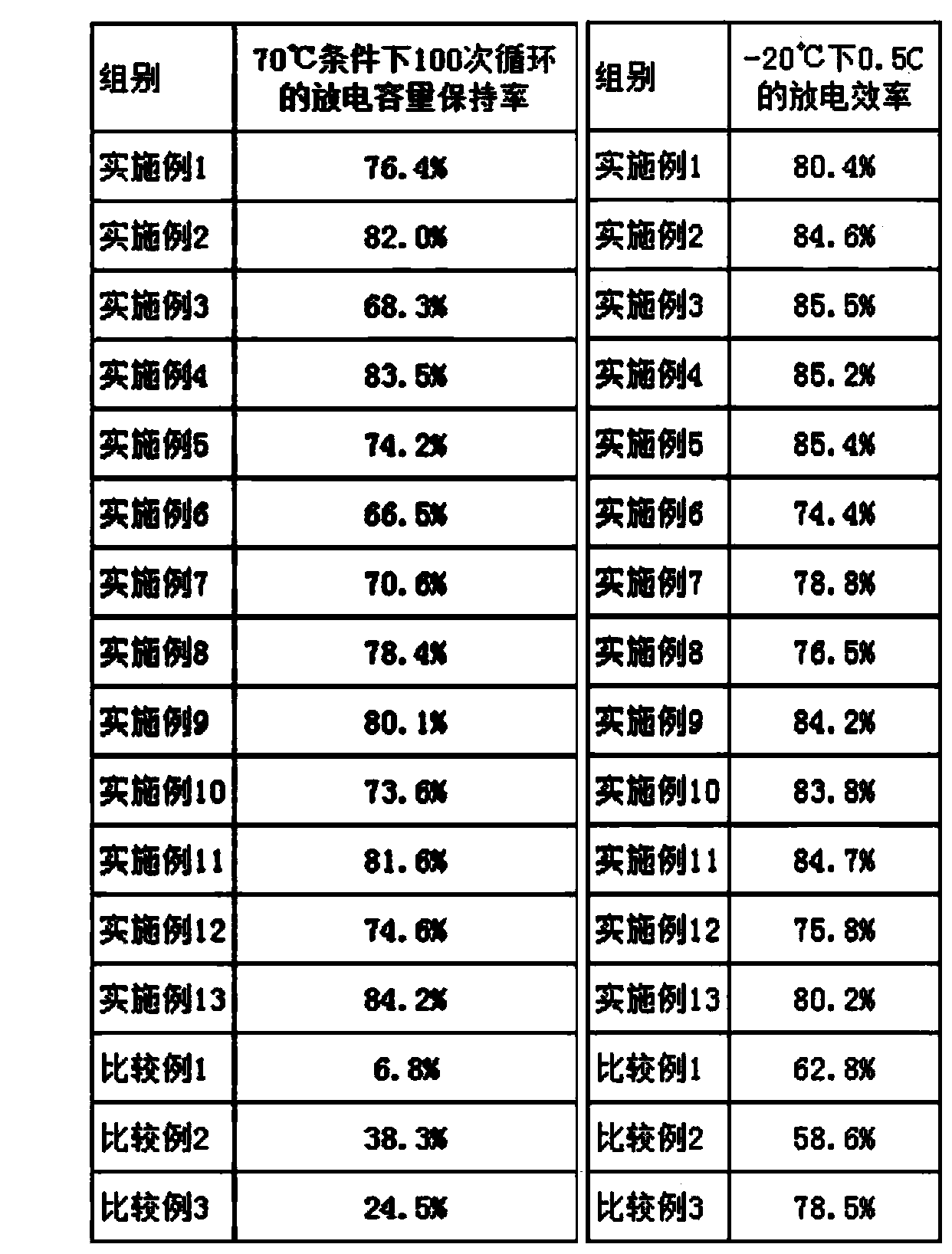

Examples

Embodiment 1

[0024] The production of lithium-ion battery positive electrode sheet: the active material lithium nickel cobalt manganese oxide LiNi 0.5 co 0.2 mn 0.3 o 2 , the conductive agent Super-P, and the binder PVDF were dispersed into N-methyl-2-pyrrolidone according to the mass ratio of 92:4:4, and stirred evenly to obtain the positive electrode slurry. The slurry is evenly coated on both sides of the current collector aluminum foil, dried, cold-pressed, stripped, then vacuum-dried, and the tabs are welded to make a positive electrode sheet of a lithium-ion battery that meets the requirements.

[0025] Production of lithium-ion battery negative plate:

[0026] The active material natural graphite, the conductive agent Super-P, the binder styrene-butadiene rubber SBR, and the binder carboxymethylcellulose sodium CMC are added to the solvent deionized water according to the mass ratio of 96:1.5:1.5:1, and stirred evenly to obtain Negative slurry. The slurry is evenly coated on bo...

Embodiment 2

[0032] A lithium-ion battery fabricated in the same manner as in Example 1 was used. The solvent in the electrolyte is ethylene carbonate (EC), γ-butyrolactone (GBL), and ethyl methyl carbonate (EMC) in a mass ratio of 1:1:3, and the lithium salt is lithium difluorooxalate borate (LiDFOB). The concentration is 0,9mol / L.

Embodiment 3

[0034] A lithium-ion battery fabricated in the same manner as in Example 1 was used. The solvent in the electrolyte is ethylene carbonate (EC), γ-butyrolactone (GBL), dimethyl carbonate (DMC), ethyl methyl carbonate (EMC) mixed in a mass ratio of 1:1:1.5:1.5, lithium salt Lithium difluorooxalate borate (LiDFOB), the concentration is 1mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com