Optical fiber on-line surface plasmon Airy light beam generator

A surface plasmon and beam generator technology, applied in the optical field, can solve the problems of low precision, large size, low laser damage threshold, etc., and achieve the effects of small size, flexible production and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

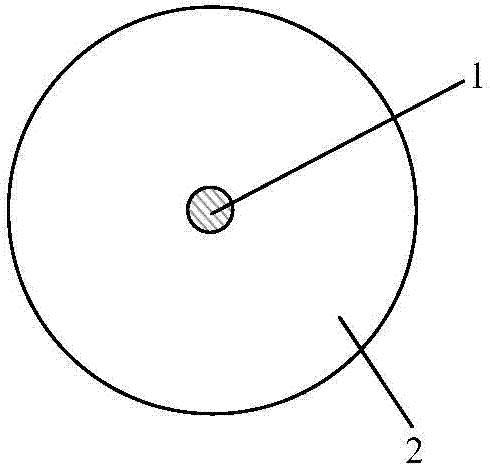

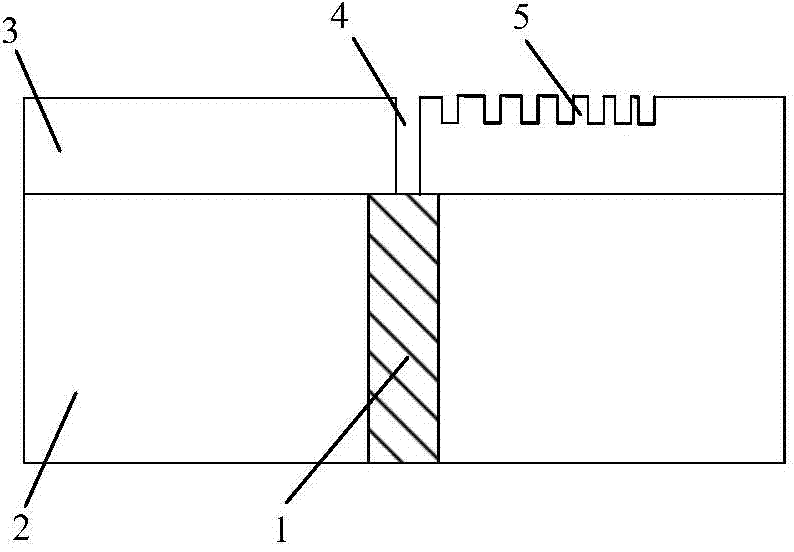

[0030] Fiber-optic online surface plasmon dual Airy beam generator (Fig. 1 and Figure 5 ), the end face of the optical fiber is coated with a 200nm thick gold film 3, and then a single slit 4 with a depth of 200nm, a width of 130nm and a length of 3 microns is carved on the central axis of the fiber core 1 by using focused ion beam technology. Then engrave an array of microgrooves 5 on the right side of the fiber core, the interval between adjacent grooves is a gradient change, and the spatial position of each groove from a single slit is determined by the formula φ 0 + k spp x + 2 nπ = 2 3 ( x x 0 ) 3 / 2 + ...

Embodiment 2

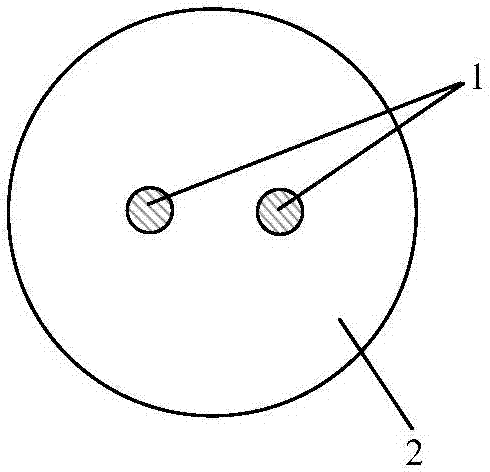

[0032] Online surface plasmon dual Airy beam generator based on dual-core fiber (Fig. 2 and Figure 6 ), the two core materials of the dual-core fiber are exactly the same size, symmetrically distributed, and the spacing is 50 microns. First, make a mark on the side of the fiber to facilitate micromachining to find the position of the fiber core. A gold film 3 with a thickness of 200 nanometers is plated on the end face of the dual-core optical fiber, and then a single slit 4-1 and 4 with a depth of 200 nanometers, a width of 130 nanometers, and a length of 3 microns is respectively carved on the central axis of the two fiber cores 1 by using focused ion beam technology. -2. Then engrave array microgrooves 5-1 and 5-2 of the same structure on the right side of the fiber core 1-1 and the left side of the fiber core 1-2, the interval between adjacent grooves is a gradient change, and each groove distance is one The spatial position of the seam is given by the formula ...

Embodiment 3

[0034] On-line surface plasmon dual Airy beam generator based on dual-core fiber ( image 3 ), the two core materials of the dual-core fiber are exactly the same size, symmetrically distributed, and the spacing is 50 microns. First, make a mark on the side of the fiber to facilitate micromachining to find the position of the fiber core. A gold film 3 with a thickness of 200 nanometers is plated on the end face of the dual-core optical fiber, and then a single slit 4-1 and 4 with a depth of 200 nanometers, a width of 130 nanometers, and a length of 3 microns is respectively carved on the central axis of the two fiber cores 1 by using focused ion beam technology. -2. Then engrave array microgrooves 5-1 and 5-2 of the same structure on the right side of the fiber core 1-1 and the left side of the fiber core 1-2, the interval between adjacent grooves is a gradient change, and each groove distance is one The spatial position of the seam is given by the formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com