Blade positioning apparatus capable of optimizing optical-fiber cutting quality

A technology of positioning device and cutting device, which is applied to the coupling of optical waveguides, glass manufacturing equipment, metal processing, etc., can solve the problems of reducing work efficiency, reducing cutting quality, and complicated operation, and achieves cost saving and optimization of fiber cutting quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

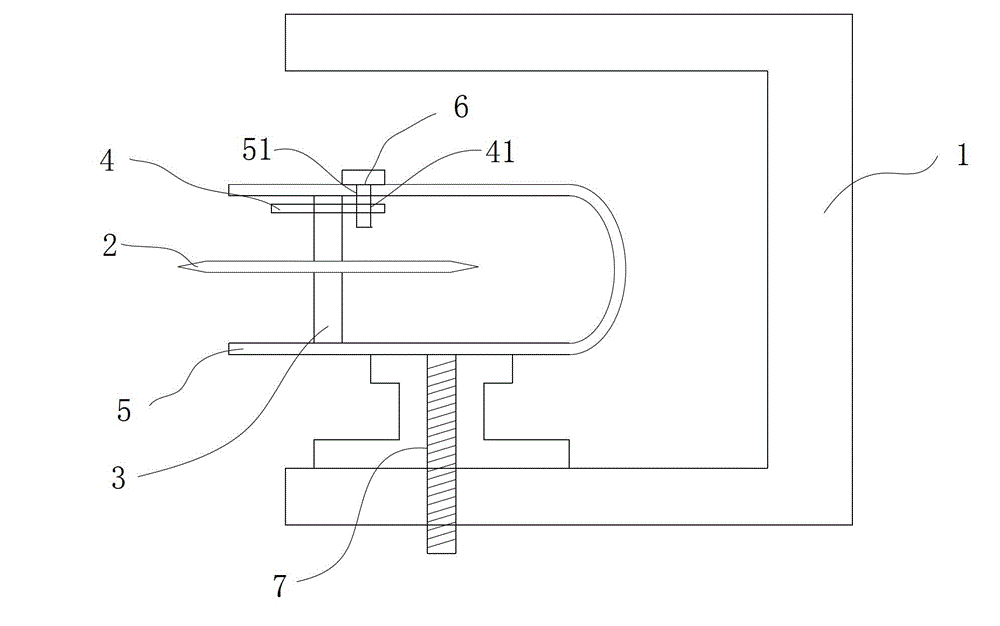

[0013] A blade positioning device that can optimize the quality of optical fiber cutting, the device is installed on the cutting device 1 of the optical fiber cutting tool, the circular blade 2 of the optical fiber cutting tool is positioned and installed through the blade positioning device, and the blade positioning device includes a height adjustment mechanism 7 and the cutting surface conversion mechanism, its specific structure is as figure 1 shown.

[0014] The height adjustment mechanism 7 is directly arranged on the cutting device 1, and adopts an Acme screw or a ball screw to easily adjust the positioning height of the blade, effectively preventing the unevenness of the cutting surface of the optical fiber from affecting the welding quality. The cutting surface conversion mechanism includes a blade positioning shaft 3, a positioning pin 6, and a U-shaped positioning block 5 arranged laterally on the height adjustment mechanism 7. The blade positioning shaft 3 passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com