A light guide structure of a flat panel display and a flat panel display with the light guide structure

A flat-panel display and flat-panel display technology, applied in the field of display screens, can solve problems such as affecting display effects, visual discomfort, and small light-emitting area, and achieve the effects of improving display contrast, improving light mixing effects, and expanding viewing angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

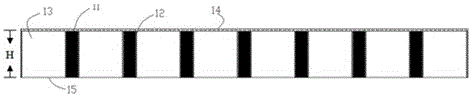

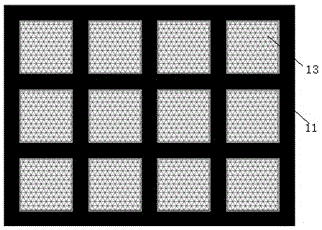

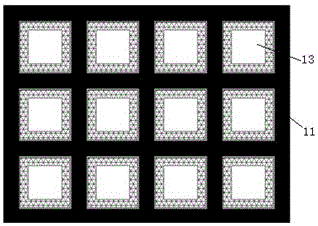

[0030] Such as figure 1 As shown, it is a structural schematic diagram of a specific embodiment of a light guide structure of a flat panel display according to the present invention. see figure 1 In this specific embodiment, a light guide structure of a flat panel display includes an incident surface 15 for introducing light emitted by a flat panel display panel and a light exit surface for emitting light, and several optical guides are arranged between the incident surface 15 and the light exit surface. The light part 13 is provided with a diffusion layer 14 on the light exit surface of the light guide structure, a partition 11 is provided between the optical light guide parts 13 , and a reflective layer 12 is also provided between the optical light guide part 13 and the partition 11 . In a specific application, the light guide structure is directly arranged on the surface of the flat panel display panel where the light exits, and the incident surface 15 of the light guide s...

Embodiment 2

[0039] According to the light guide structure of the flat-panel display in Embodiment 1 above, the present invention also provides a flat-panel display. A flat-panel display of the present invention includes a flat-panel display panel and the above-mentioned light-guiding structure of the flat-panel display, and the light-guiding structure is arranged on the surface of the flat-panel display panel where light is emitted. After the light of single or multiple display pixels on the flat panel display exits from the surface of the flat panel display panel and enters the optical light guide part from the incident surface of the light guide structure, it is reflected multiple times in the optical light guide part by the reflection of the reflective layer. After passing through the light-emitting surface of the light guide structure, it enters the diffusion layer, and finally exits from the diffusion layer. The light has a better light mixing effect due to multiple reflections in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com