Test bed device for tunnel excavating and grouting model and application method of device

A test bench and tunnel excavation technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of no geological disasters, etc., and achieve the effect of satisfying repeatability, convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below in conjunction with accompanying drawing:

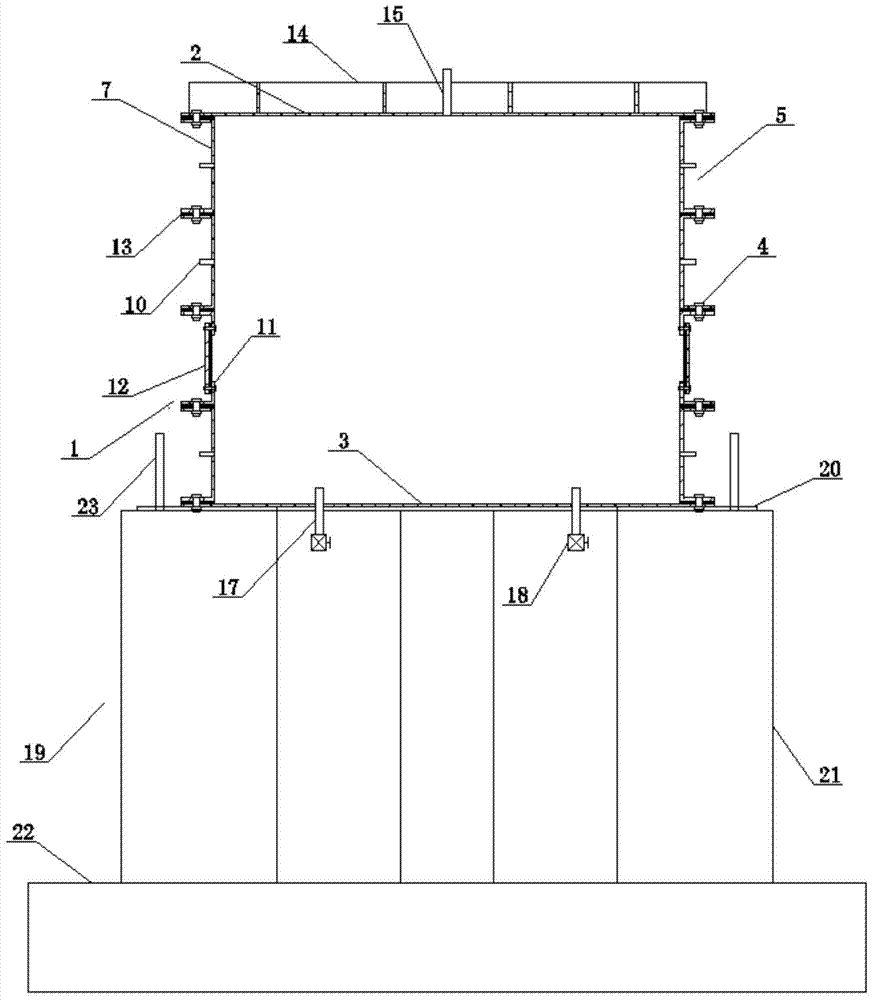

[0046] A tunnel excavation and grouting model test bench device, which can continuously and systematically simulate the occurrence of geological disasters during tunnel excavation and the subsequent grouting reinforcement process. The device includes a bottom plate 3, a side wall 1, and a top cover 2 and 19 reinforced concrete support frames.

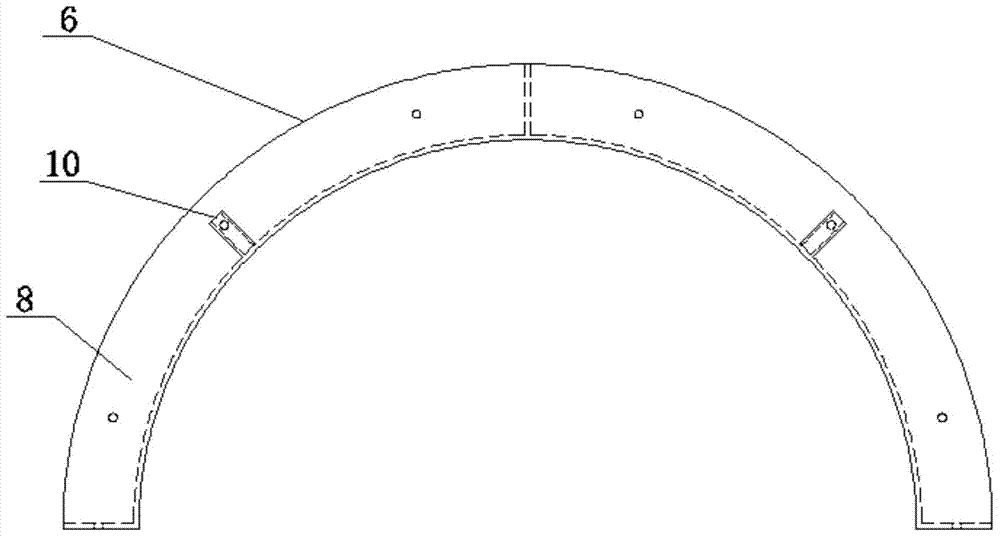

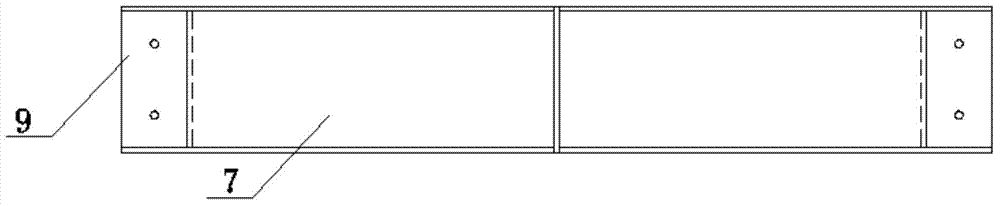

[0047] The side wall 1 in the test bench is formed by connecting a model ring unit 5 with a height of 300 mm through high-strength bolts 4 . The model ring unit 5 is composed of two semi-arc units 6, and the semi-arc unit 6 is composed of an arc plate 7, a semi-circular rib plate 8, and a vertical rib plate 9. The arc plate 7 is 10mm thick and 1500mm in diameter. The top and bottom of the arc plate 7 are welded along the edge with a 100mm wide and 10mm thick semi-circular rib plate 8. Both ends and the middle are welded with a vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com