Flowing wet vapor humidity measurement probe based on microwave heating and measurement method thereof

A flow wet steam and humidity measurement technology, which is applied in the direction of material moisture content, can solve the problems of difficult accurate measurement of heating capacity, long heating section, and easy damage of heating elements, so as to reduce heat dissipation and thermal inertia, and improve Measurement accuracy, effect of reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

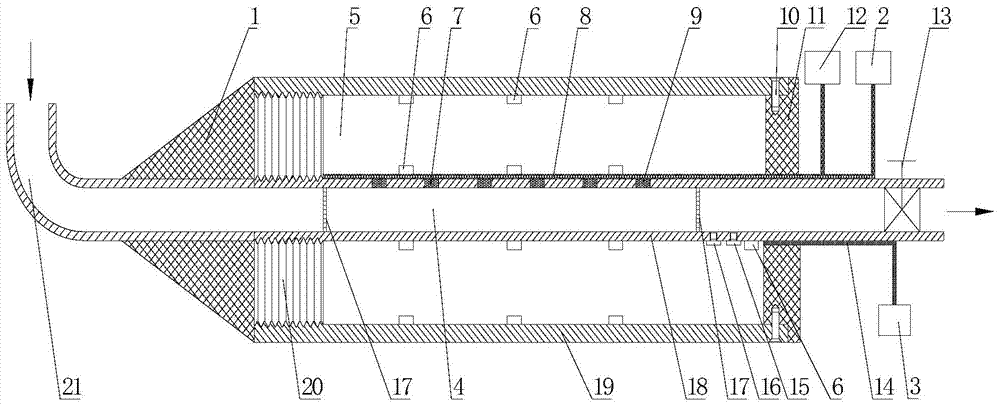

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] refer to figure 1 , the flow wet steam humidity measurement probe based on microwave heating according to the present invention includes a bracket 1, a sampling head 21, an inner tube 18, an outer tube 19, a rear end cover 11, a vacuuming device, a microwave power meter 12, and a microwave source 2 , coaxial line 8, microwave cavity 4 and data acquisition system 3;

[0024] The sampling head 21 is welded on the bracket 1, one end of the inner tube 18 is connected with the sampling head 21, one end of the outer sleeve 19 is fixed on the bracket 1, the other end of the outer sleeve 19 is sealed and connected with the rear end cover 11, and the inner tube The other end of 18 passes through the rear end cover 11 and is connected to the vacuuming equipment through the regulating valve 13, the inner tube 18 and the outer tube 19 are filled with thermal insulation mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com