Method for quickly determining permeability of working surface front coal body of underground coal mine in lab

A permeability, working face technology, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., can solve problems such as deviation, poor operating environment, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention provides a method for quickly measuring the permeability of the coal body in front of the working face of a coal mine in the laboratory. The example of rate determination further illustrates the present invention.

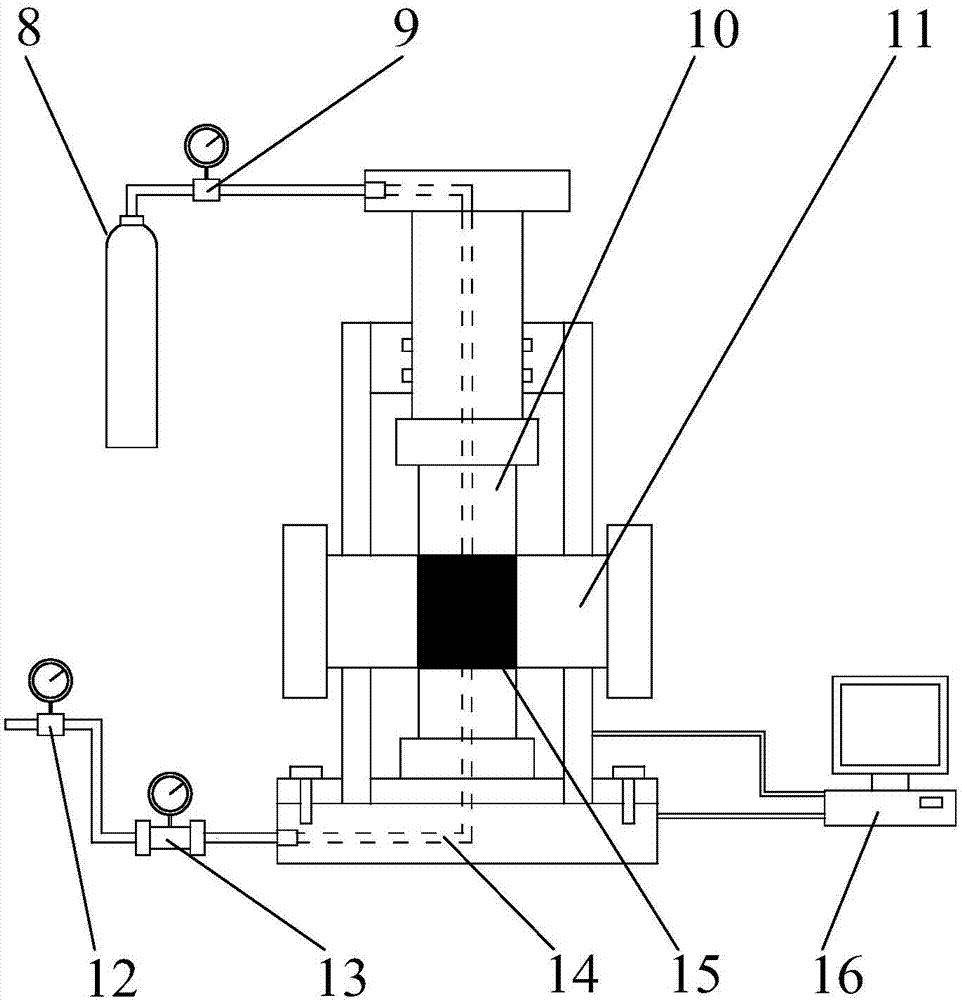

[0041] Firstly, the selected experimental hardware of the present invention: the mining stress monitoring system and the true triaxial permeability testing system are explained as follows:

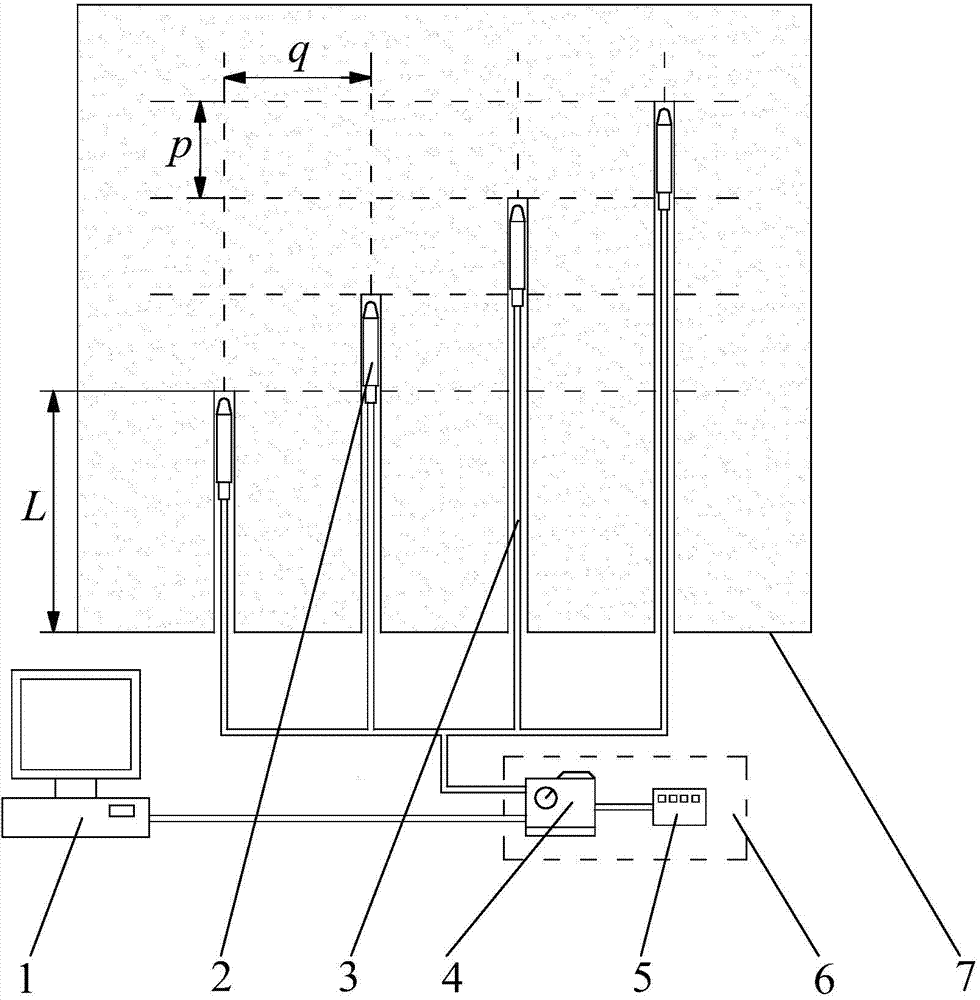

[0042] combine figure 1 As shown, the mining stress monitoring system includes a system host 1, a drilling stress gauge 2, a guide rod 3, a regulator 4 and a stabilized power supply 5, wherein the main function of the system host 1 is to collect monitoring data, and on the other hand, the data Carry out classification, processing, and display the data report with the man-machine dialogue interface; the guide rod 3 is used to send the drilling stress gauge 2 to the preset drilling position, and the drilling stress gauge 2 is connected to the input p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com