Assembly method for LED lamp

A technology of LED lamps and assembly methods, which is applied to lighting devices, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of high cost and low assembly efficiency, and achieve low cost, high installation efficiency, and no welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

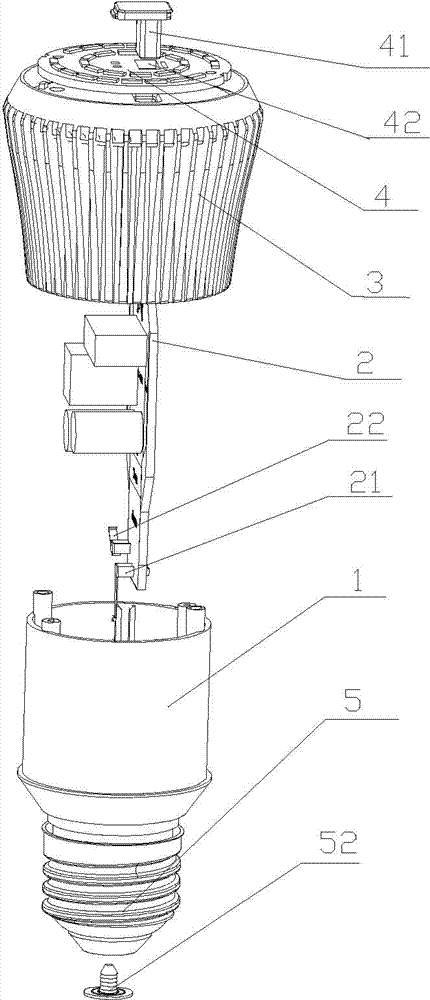

[0028] The efficient LED lamp assembly method of the present invention comprises the following steps:

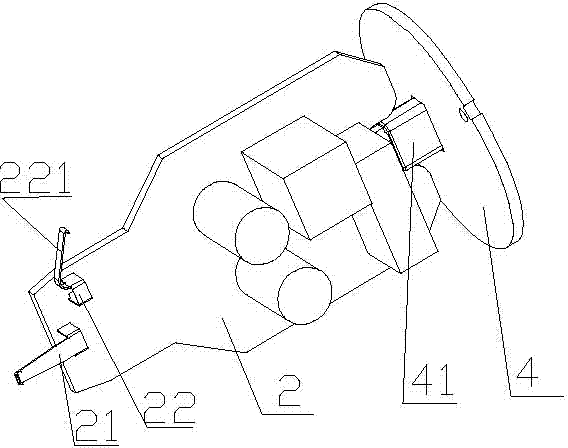

[0029] The P pole piece 21 and the N pole piece 22 are respectively electrically connected (welded) to the power drive board 2 of the LED lamp. Both the P pole piece 21 and the N pole piece 22 are made of beryllium copper material, which has certain elasticity. , can be more convenient to install. The P pole piece 21 is processed in the middle of the end of the power drive board 2 so as to be combined with the lamp head, and the N pole piece 22 is processed on the side of the power drive board 2 so as to be combined with the lamp housing 1. Please refer to the attached product for the product. figure 2 .

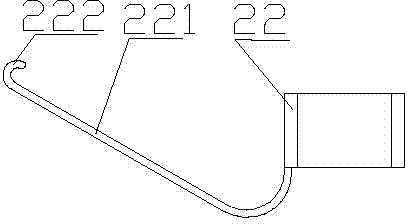

[0030] And the N pole piece 22 is processed with a bent part 221, the bent part 221 faces the side direction of the power drive board 2, and a hook part 222 can also be processed at the end of the bent part 221. For the product, refer to the attached image 3 .

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com