Universal Vector Photography Camera Bracket

A camera bracket and vector technology, applied in the direction of machine/bracket, supporting machine, mechanical equipment, etc., can solve the problems of long adjustment time, troublesome operation, inability to work for a long time, etc., and achieve the effect of flexible angle change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

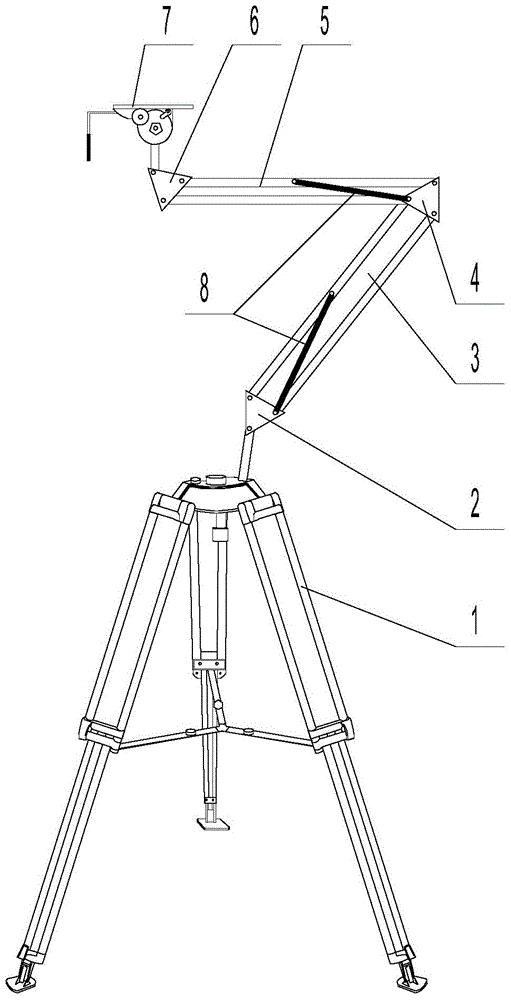

Embodiment 1

[0035] figure 1 Disclosed in is a kind of universal vector photographic camera bracket, comprising a shooting support device 1, a lower mechanical arm 3, an upper machine 5, and a pan-tilt tray 7. The shooting support device 1 is a tripod, and the top of the shooting support device 1 Connecting seat A2 is detachably connected by a fastener, and the bottom of the pan-tilt tray 7 is detachably connected to a connecting seat C6 by a fastener; the bottom end of the lower mechanical arm 3 is hinged with the connecting seat A2, and the lower mechanical arm The top of 3 is hinged with the bottom end of upper mechanical arm 5 through connecting seat B4, and the top of upper mechanical arm 5 is hinged with connecting seat C6.

[0036] The upper mechanical arm 3 and the lower mechanical arm 5 are both composed of two parallel pipe arms, and the two ends of the two parallel pipe arms of the lower mechanical arm 3 are respectively hinged with the connecting seat A2 and the connecting seat...

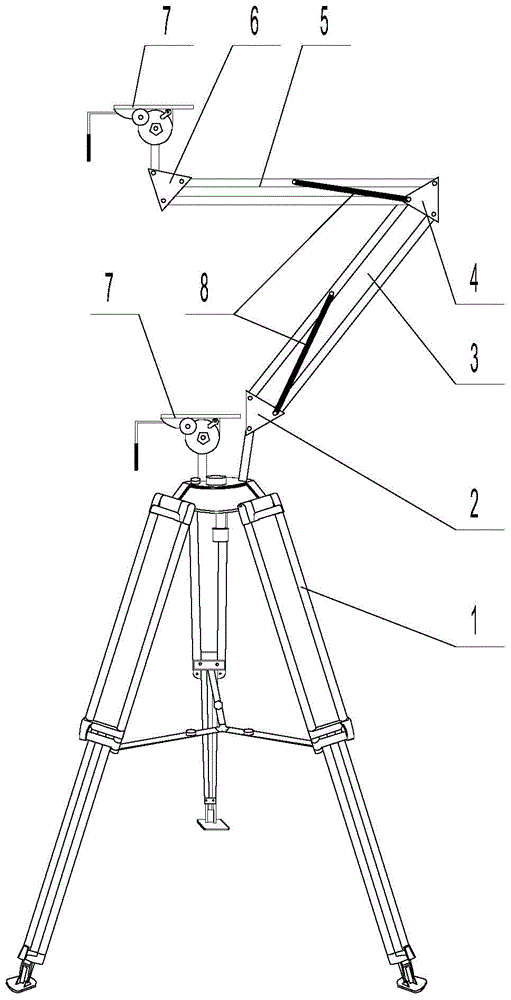

Embodiment 2

[0040] figure 2 What is disclosed in is a universal vector photography camera bracket with two camera positions. The basic structure of the bracket is the same as that of Embodiment 1, the difference is that: the top of the tripod used as the shooting support device 1 is also connected with a cloud platform Tray 7, the structure of this universal vector photography camera bracket is as follows:

[0041] A kind of universal vector photographic camera bracket, comprising a shooting support device 1, a lower mechanical arm 3, an upper machine 5, and a pan-tilt tray 7. The shooting support device 1 is a tripod, and the top of the shooting support device 1 is passed through a fastener The connecting seat A2 is detachably connected, and the bottom of the pan-tilt tray 7 is detachably connected with the connecting seat C6 through fasteners; the bottom end of the lower mechanical arm 3 is hinged with the connecting seat A2, and the top end of the lower mechanical arm 3 is The connec...

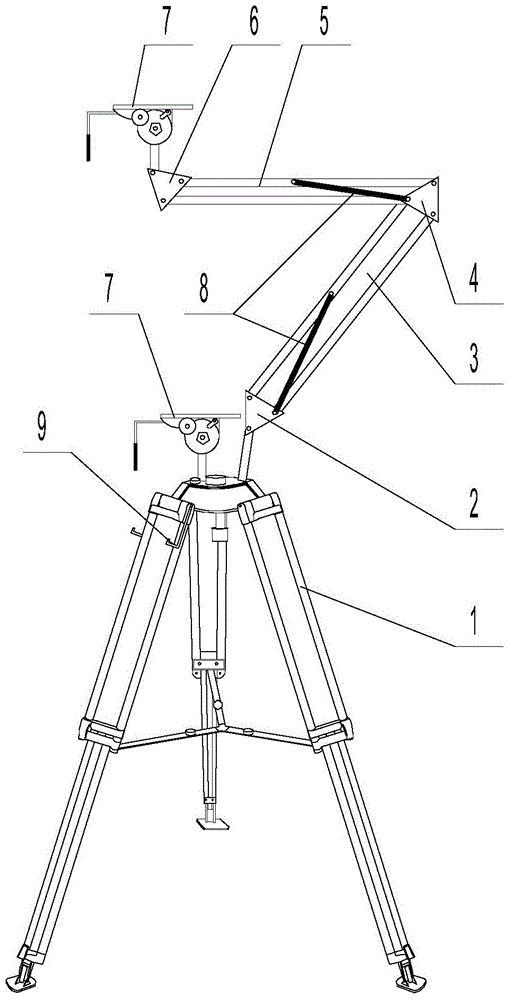

Embodiment 3

[0045] image 3 Disclosed in is another kind of universal vector photographic camera bracket, the basic structure of this bracket is the same as that of Embodiment 2, the difference is that: the top of the tripod as the shooting support device 1 is also connected with a viewfinder placement platform 9 , the structure of the universal vector photography camera bracket is as follows:

[0046] A kind of universal vector photographic camera bracket, comprising a shooting support device 1, a lower mechanical arm 3, an upper machine 5, and a pan-tilt tray 7. The shooting support device 1 is a tripod, and the top of the shooting support device 1 is passed through a fastener The connecting seat A2 is detachably connected, and the bottom of the pan-tilt tray 7 is detachably connected with the connecting seat C6 through fasteners; the bottom end of the lower mechanical arm 3 is hinged with the connecting seat A2, and the top end of the lower mechanical arm 3 is The connecting seat B4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com