Prefabricated concrete bearing platform with reserved foundation ring hole and reserved pile nest holes and fabricated multi-pile foundation installation method based on prefabricated concrete bearing platform with reserved foundation ring hole and reserved pile nest holes

A technology of prefabricated concrete and installation method, which is applied in the direction of basic structure engineering and construction, and can solve problems such as long period, strict foundation flatness requirements, and complicated construction process, so as to save construction time, save formwork removal procedures, and reduce construction costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

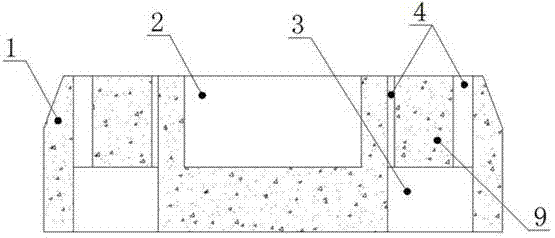

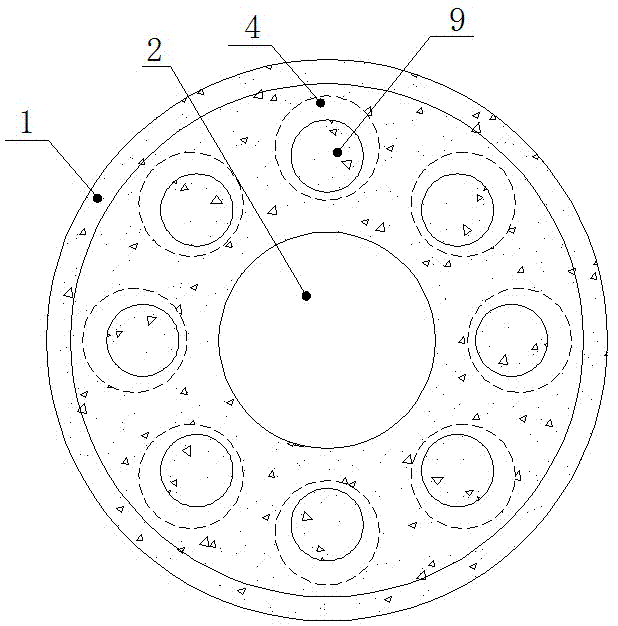

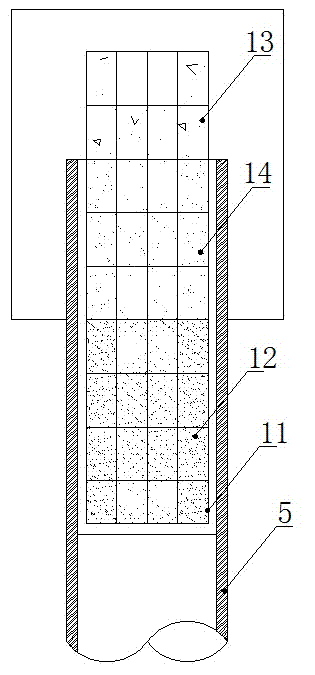

[0042] figure 1 , 2 Shown is a prefabricated concrete cap with reserved foundation ring holes and pile socket holes, including a concrete body 1, and a reserved foundation ring hole 2 coaxial with the concrete body 1 is provided at the center of the top surface of the concrete body 1, The bottom of the concrete body 1 corresponds to the position of the pile foundation 5, and the reserved pile holes 3 are arranged circularly (evenly setting is the best), and the top of each reserved pile hole 3 is provided with grouting that penetrates the top surface of the concrete body 1 The tunnel 4; a plurality of lifting lugs are uniformly arranged on the circumferential side of the concrete body 1 . ( figure 1 , 2 The concrete body 1 shown in is a circular concrete body).

[0043] Depend on figure 2 It can be seen that the grouting channel 4 involved in this embodiment is an eccentric annular channel (circular), that is, the distance from the outer side of the ring wall of the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com