White granulated sugar production technology

A production process, white granulated sugar technology, applied in sucrose production, sugar production, sugar juice purification, etc., can solve the problems of large amount of waste water, small adsorption amount, slow process flow, etc., to reduce waste water discharge and quantity , The effect of reducing evaporation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

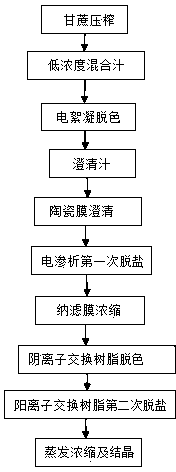

Method used

Image

Examples

Embodiment

[0026] Step 1: Take organic sugarcane and squeeze it to get mixed juice, prelime the mixed juice to pH6.5, heat it once to 60-65°C, add lime milk to adjust pH=5.5-6.5, and enter the electrocoagulation equipment; the electrocoagulation Equipment condition:

[0027] Aluminum electrode: use 400mmx260mm electrode sheet;

[0028] Electrolyzer: Rectangular plexiglass electrolyzer, size 270mmx120mmx420mm;

[0029] Power supply: WYJ30-3-I high stability DC power supply, voltage 1-30V, current 0-3A;

[0030] The electrolysis time is 15 minutes, the temperature is maintained above 30°C, and the voltage is 20V.

[0031] Add polyacrylamide of 1‰ polyacrylamide to the electrocoagulation effluent, stir, and stir for 20 minutes, and the color of the precipitation and precipitation process will be reduced from 3000IU to 1000IU;

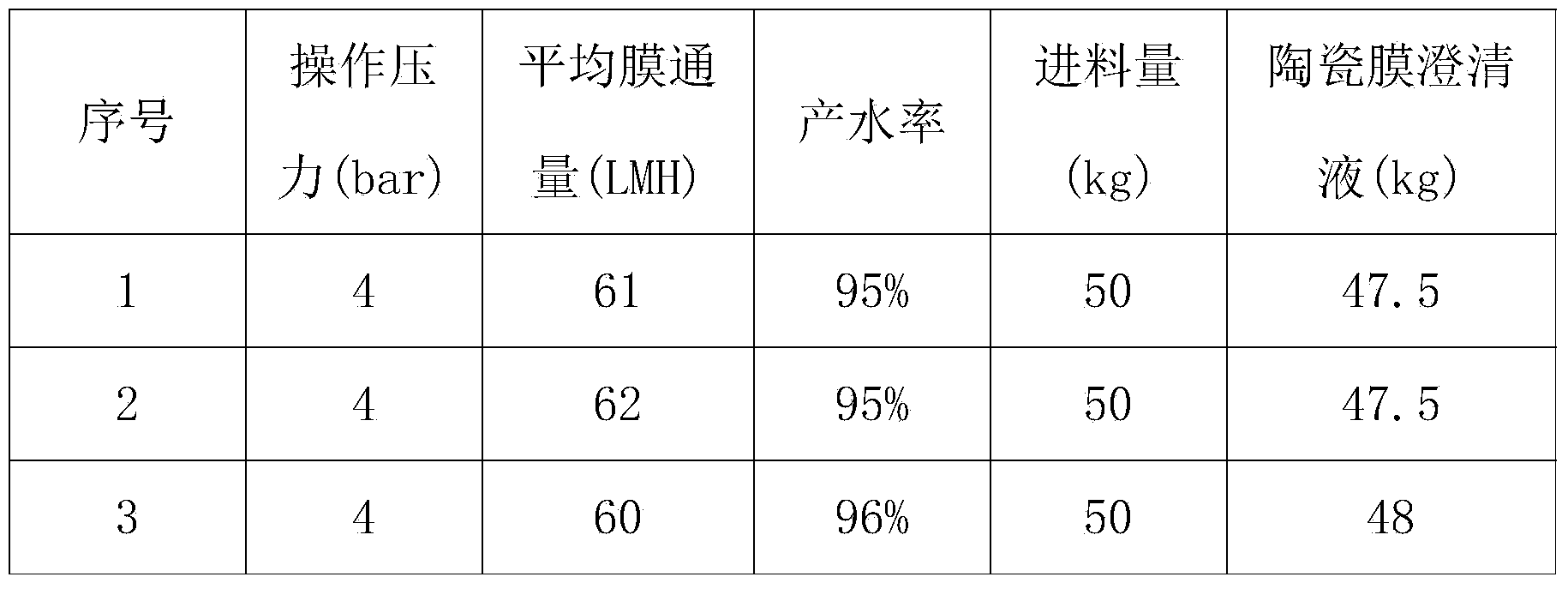

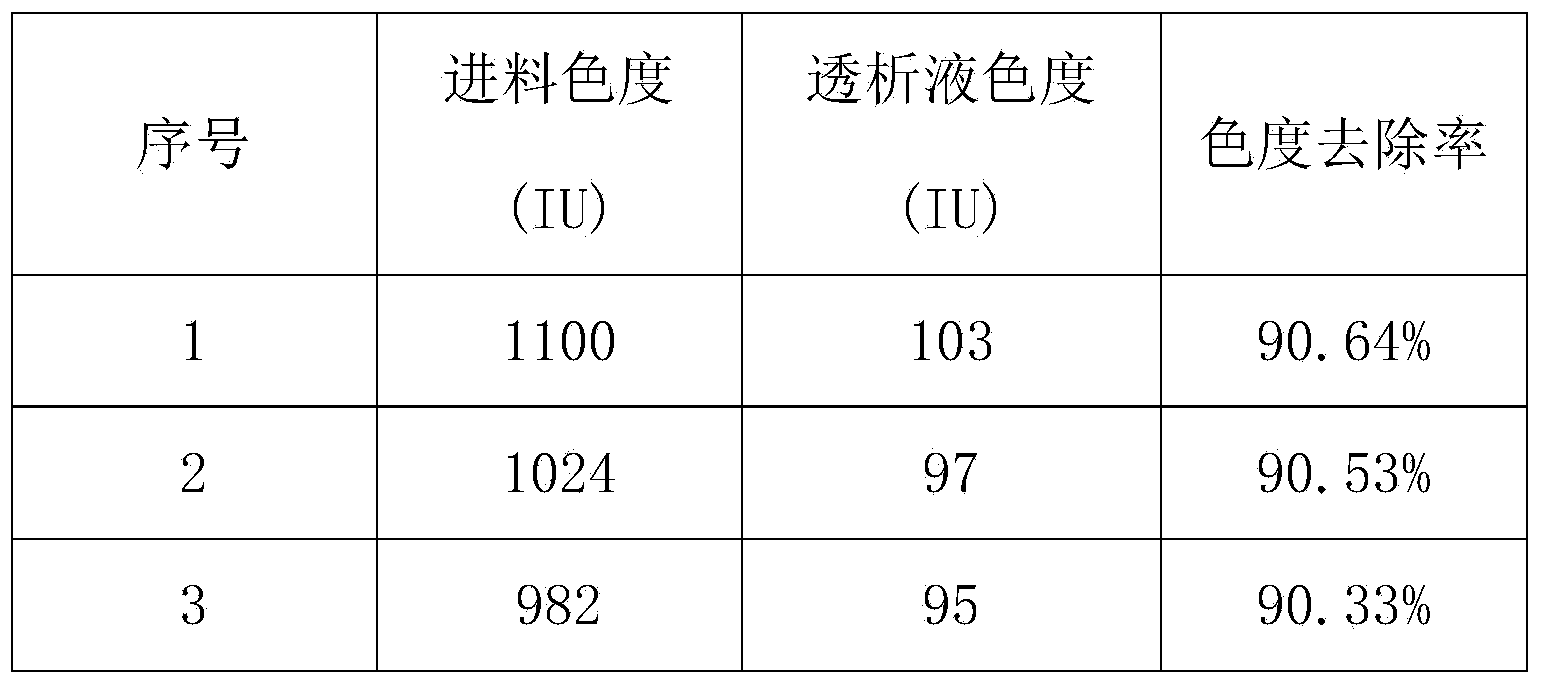

[0032] Step 2: Take 50KG of the supernatant and enter the ceramic membrane separation system. The water production rate of the ceramic membrane is 95%, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com