Efficient cutting gas synergist, preparation method thereof as well as special adding equipment and method of efficient cutting gas synergist

A technology of special equipment and synergist, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems that need to be further clarified and improved, and cannot achieve the cutting effect of acetylene gas, and achieve stable properties and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

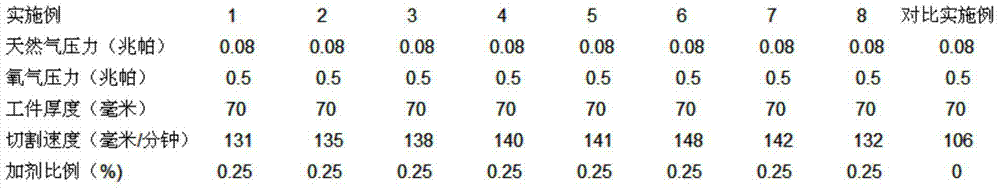

Examples

Embodiment 1

[0049] A high-efficiency cutting gas synergist, consisting of component A, component B and component C, wherein:

[0050] Component A: prepared from 25 parts by weight of isooctyl nitrate, 10 parts by weight of cyclohexyl nitrate and 8 parts by weight of dicumyl peroxide;

[0051] Component B: prepared from 40 parts by weight of di-tert-butyl peroxide and 15 parts by weight of di-t-amyl peroxide;

[0052] Component C: 2 parts by weight of ferrocene.

[0053] The preparation method of this embodiment is:

[0054] (1) Preparation of component A: add isooctyl nitrate, cyclohexyl nitrate, and dicumyl peroxide into the explosion-proof glass-lined reaction kettle in sequence in proportion, start stirring at a speed of 80 rpm, and stop stirring for 2 minutes Stir and stop for a while to pack in a 25kg plastic bucket;

[0055] (2) Preparation of component B: Add di-tert-amyl peroxide and di-tert-butyl peroxide in sequence in proportion to the explosion-proof glass-lined reaction ke...

Embodiment 2

[0059] A high-efficiency cutting gas synergist, consisting of component A, component B and component C, wherein:

[0060] Component A: prepared from 25 parts by weight of isooctyl nitrate, 10 parts by weight of cyclohexyl nitrate and 5 parts by weight of dicumyl peroxide;

[0061] Component B: prepared from 40 parts by weight of di-tert-butyl peroxide and 15 parts by weight of di-t-amyl peroxide;

[0062] Component C: 5 parts by weight of ferrocene.

[0063] The preparation method of the present embodiment is as follows:

[0064] (1) Preparation of component A: add isooctyl nitrate, cyclohexyl nitrate, and dicumyl peroxide into the explosion-proof glass-lined reaction kettle in sequence in proportion, start stirring at a speed of 80 rpm, and stop stirring for 2 minutes Stir and stop for a while to pack in a 25kg plastic bucket;

[0065] (2) Preparation of Component B: add di-tert-amyl peroxide and di-tert-butyl peroxide into the explosion-proof glass-lined reaction kettle i...

Embodiment 3

[0069] A high-efficiency cutting gas synergist, consisting of component A, component B and component C, wherein:

[0070] Component A: prepared from 25 parts by weight of isooctyl nitrate, 10 parts by weight of cyclohexyl nitrate and 5 parts by weight of dicumyl peroxide;

[0071] Component B: prepared from 37 parts by weight of di-tert-butyl peroxide and 15 parts by weight of di-t-amyl peroxide;

[0072] Component C: 8 parts by weight of ferrocene.

[0073] The preparation method of the present embodiment is as follows:

[0074] (1) Preparation of component A: add isooctyl nitrate, cyclohexyl nitrate, and dicumyl peroxide into the explosion-proof glass-lined reaction kettle in sequence in proportion, start stirring at a speed of 98 rpm, and stop stirring for 8 minutes Stir and stop for a while to pack in a 25kg plastic bucket;

[0075] (2) Preparation of component B: Add di-tert-amyl peroxide and di-tert-butyl peroxide in sequence in proportion to the explosion-proof glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com