Fluorine-containing polymer free of perfluoro-octanoic acid or perfluoro-octylsulfonic acid

A technology of perfluorooctane sulfonic acid and perfluorooctanoic acid, applied in the field of fluoropolymer synthesis, can solve the problem that the production efficiency has not made any substantial improvement, the yield and particle size of the fluoropolymer are not involved, and there is no way to achieve large-scale production and other problems, to achieve the effect of being suitable for widespread use, not easy to enrich, and increasing the yield of a single kettle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

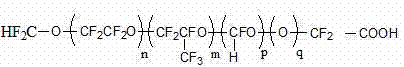

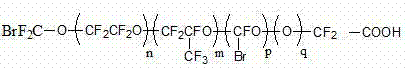

[0091] The liquid-phase polymerization involved in the present invention is a conventional preparation method of fluorine-containing polymers. In the present invention, the liquid-phase polymerization refers to aqueous emulsion polymerization, and the aqueous emulsion polymerization system in the polymerization process mainly includes fluorinated monomers Body, initiator, water, emulsifier four basic components, known, we found a new fluorine-containing emulsifier (ie: polyfluoroalkoxy ether acid emulsifier) to replace PFOA / PFOS, And the fluorine-containing polymer that makes can be solid, and does not contain perfluorooctanoic acid or perfluorooctanoic acid, certainly, in order to better realize the present invention, we also need to fluorine-containing monomer, initiator, polyfluoroalkoxy The ratio of base ether acid emulsifier to water is selected, and both are indispensable. In the invention, there are mainly two types of initiators: inorganic peroxides (such as persulfa...

Embodiment 1

[0098] Polytetrafluoroethylene is prepared from the gaseous fluorinated monomer-tetrafluoroethylene through aqueous emulsion polymerization, and 1-bromo-polyfluoroalkoxyether acid is added to the aqueous emulsion polymerization as a fluorine-containing emulsifier. The specific implementation steps as follows:

[0099] A: Prepare the aqueous solution of the salt of 1-bromo-polyfluoroalkoxycarboxy ether acid: add 700ml of deionized water and 100ml of 25% ammonia water to a 2000ml glass beaker, and then pour it into the deionized water slowly and uniformly through the glass dropping funnel Add dropwise the 1-bromo-polyfluoroalkyl carboxylic acid of 200g, stir while dripping, the stirring speed is 80 rpm, then, obtain polyfluoroalkoxy ether acid ammonium aqueous solution for subsequent use, wherein, 1-bromo -The weight ratio of ammonium polyfluoroalkoxy carboxy etherate to water is 20:100;

[0100] B: Polymerization preparation: Replace the high-pressure polymerization kettle wit...

Embodiment 2

[0112] Polychlorotrifluoroethylene is prepared from gaseous fluorinated monomer—chlorotrifluoroethylene through aqueous emulsion polymerization, and 1-bromo-polyfluoroalkoxy carboxylether acid is added in the aqueous emulsion polymerization as a fluorine-containing emulsifier. The specific implementation steps are as follows:

[0113] A: Prepare the aqueous solution of the salt of 1-bromo-polyfluoroalkoxycarboxy ether acid: add 2800ml of deionized water and 400ml of 25% ammonia water in a 5000ml glass beaker, and then slowly and uniformly pour into the deionized water through the glass dropping funnel Add dropwise the 1-bromo-polyfluoroalkyl carboxylic acid of 800g, stir while dripping, the stirring speed is 80 rpm, then, obtain polyfluoroalkoxy ether acid ammonium aqueous solution for subsequent use, wherein, 1-bromo - The weight ratio of poly(polyfluoroalkoxy carboxy ether ammonium acid) to water is 20:100;

[0114] B: Polymerization preparation: replace the high-pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com