a dispersion

A technology of dispersion and aqueous dispersion, applied in the field of dispersion, can solve the problems of not involving the yield and particle size of fluorine-containing polymer, refractory degradation, and no substantial improvement in production efficiency, so as to be suitable for wide popularization and use. , the effect of increased degradation performance and not easy to enrich

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

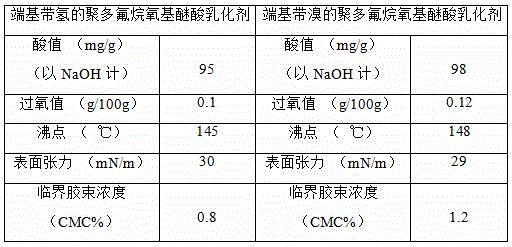

[0094] Polytetrafluoroethylene is prepared from the gaseous fluorinated monomer-tetrafluoroethylene through aqueous emulsion polymerization, and 1-bromo-polyfluoroalkoxyether acid is added to the aqueous emulsion polymerization as a fluorine-containing emulsifier. The specific implementation steps as follows:

[0095] A: Prepare the aqueous solution of the salt of 1-bromo-polyfluoroalkoxycarboxy ether acid: add 700ml of deionized water and 100ml of 25% ammonia water to a 2000ml glass beaker, and then pour it into the deionized water slowly and uniformly through the glass dropping funnel Add dropwise the 1-bromo-polyfluoroalkyl carboxylic acid of 200g, stir while dripping, the stirring speed is 80 rpm, then, obtain polyfluoroalkoxy ether acid ammonium aqueous solution for subsequent use, wherein, 1-bromo -The weight ratio of ammonium polyfluoroalkoxy carboxy etherate to water is 20:100;

[0096] B: Polymerization preparation: Replace the high-pressure polymerization kettle wit...

Embodiment 2

[0112] Polychlorotrifluoroethylene is prepared from gaseous fluorinated monomer—chlorotrifluoroethylene through aqueous emulsion polymerization, and 1-bromo-polyfluoroalkoxy carboxylether acid is added in the aqueous emulsion polymerization as a fluorine-containing emulsifier. The specific implementation steps are as follows:

[0113] A: Prepare the aqueous solution of the salt of 1-bromo-polyfluoroalkoxycarboxy ether acid: add 2800ml of deionized water and 400ml of 25% ammonia water in a 5000ml glass beaker, and then slowly and uniformly pour into the deionized water through the glass dropping funnel Add dropwise the 1-bromo-polyfluoroalkyl carboxylic acid of 800g, stir while dripping, the stirring speed is 80 rpm, then, obtain polyfluoroalkoxy ether acid ammonium aqueous solution for subsequent use, wherein, 1-bromo - The weight ratio of poly(polyfluoroalkoxy carboxy ether ammonium acid) to water is 20:100;

[0114] B: Polymerization preparation: replace the high-pressure p...

Embodiment 3

[0123] Vinylidene fluoride-chlorotrifluoroethylene is produced by aqueous emulsion polymerization of vinylidene fluoride and chlorotrifluoroethylene, and 1-chloro-polyfluoroalkoxyether-ammonium p-benzenesulfonate is added to the aqueous emulsion polymerization as the Fluorine emulsifier, the specific implementation steps are as follows:

[0124] A: Prepare the aqueous solution of the salt of 1-chloro-polyfluoroalkoxyether-p-benzenesulfonic acid: add 700ml deionized water and 100ml 25% ammonia water in a 2000ml glass beaker, then pour the deionized water through the glass dropping funnel Slowly add 200g of 1-chloro-polyfluoroalkoxyether-p-benzenesulfonic acid dropwise at a uniform speed in water, stir while adding dropwise, the stirring speed is 80 rpm, and then, obtain ammonium polyfluoroalkoxyether acid An aqueous solution, wherein the weight ratio of 1-chloro-polyfluoroalkoxy ether-ammonium p-benzenesulfonate to water is 20:100;

[0125] B: Polymerization preparation: repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com