CANON (Completely Autotrophic Nitrogen removal Over Nitrite) process starting method for MBR (Membrane Bioreactor)

A technology in the process and start-up stage, which is applied in the field of rapid start-up of the CANON process, can solve the problems of hard to obtain seed sludge, low removal load, and easy loss of sludge, so as to improve bacterial activity and treatment efficiency, prevent sludge loss, and be superior The effect of living conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

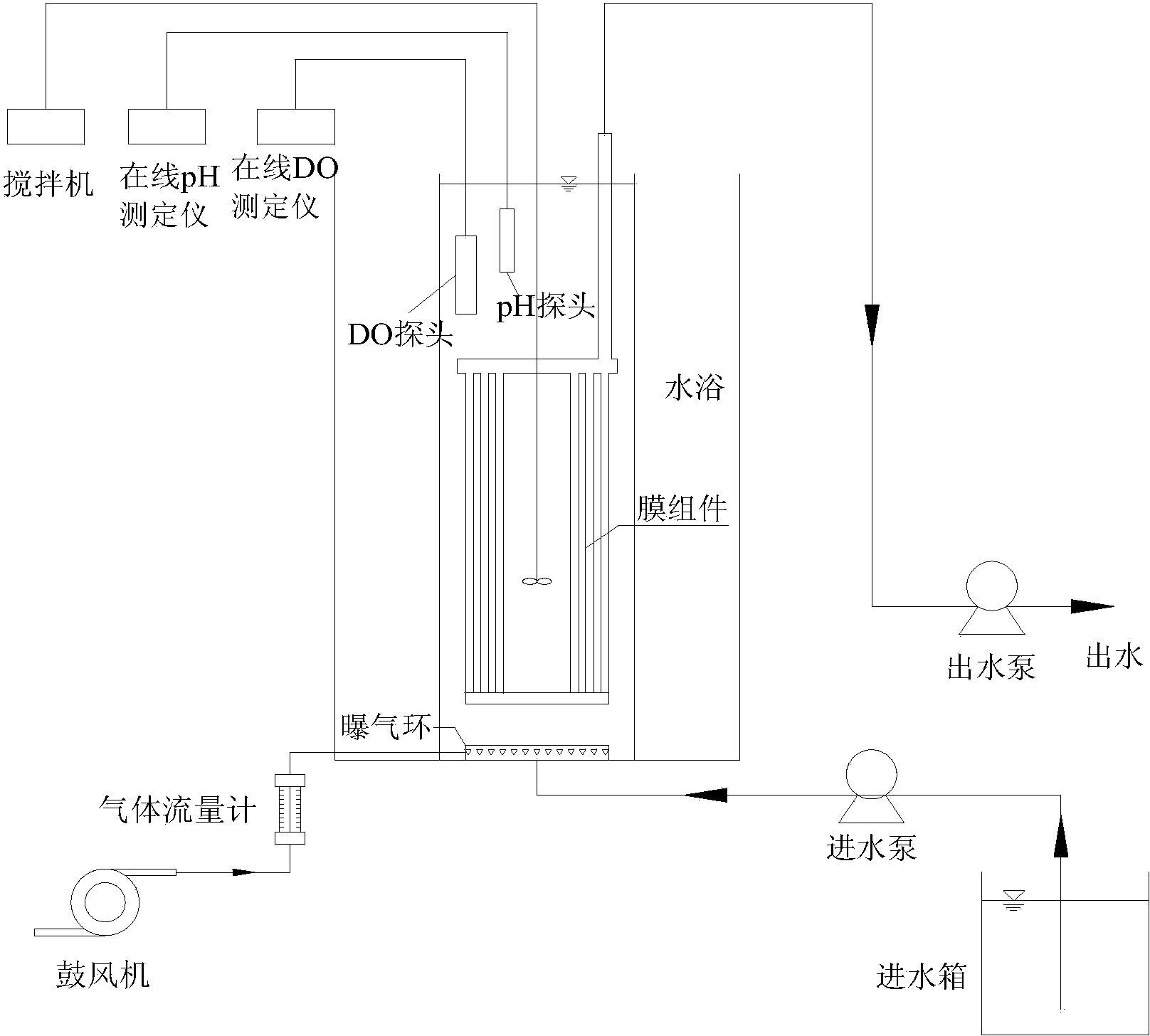

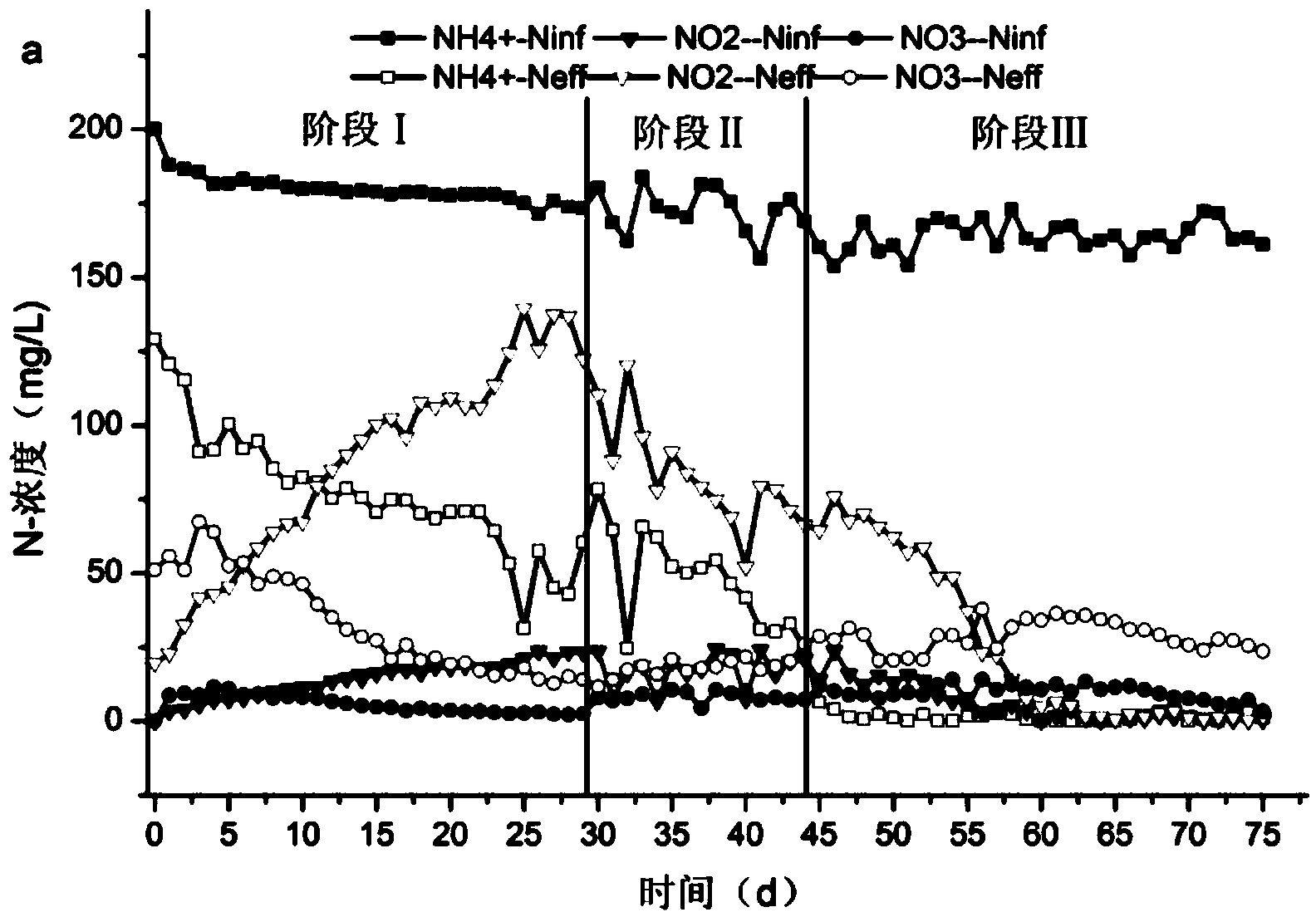

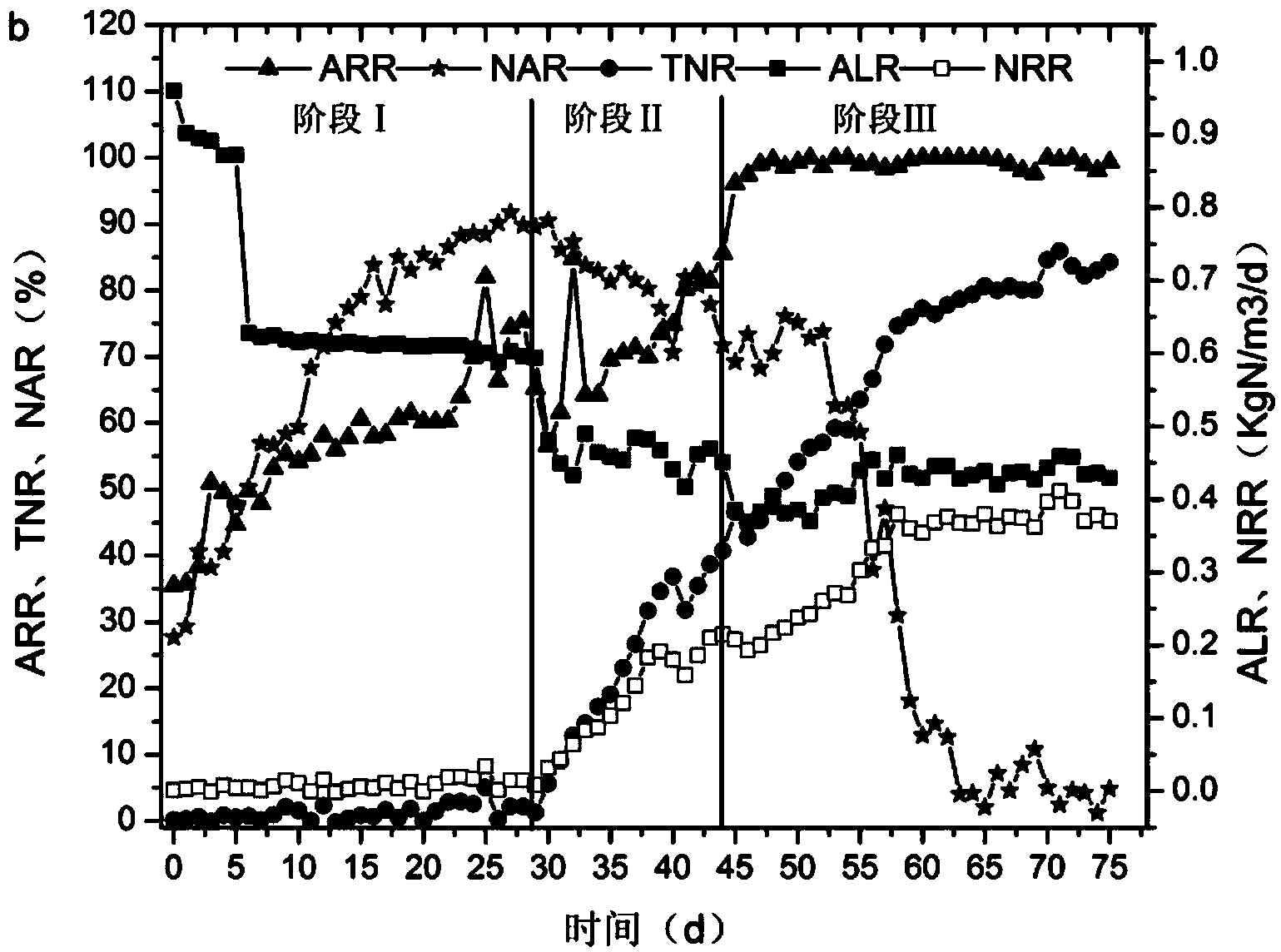

[0031] The reactor is a cylindrical MBR reactor made of plexiglass. The inner diameter of the cylinder is 13cm, the height is 40cm, the effective volume is 3L, and the built-in polyvinylidene fluoride (PVDF) hollow fiber membrane module, the membrane pore diameter is 0.1μm, and the membrane flux is 36L / h. The bottom of the reactor is equipped with an aeration plate, which adopts blower aeration, and the aeration volume is controlled by a rotameter, and there is a stirrer in the middle for substrate and O 2 Uniform diffusion, a water bath sleeve is set outside, and the temperature inside the reactor is controlled by a temperature controller. The test was inoculated with ordinary activated sludge from a sewage treatment plant, and artificially distributed water with ammonia nitrogen = 190-210 mg / L was used as the basic water, and heated by a water bath to control the temperature in the reactor to 23. From ℃ to 2 experiments at 5℃, intermittent operation is adopted. Each cycle i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com