Method for treating high-concentration ammonia nitrogen wastewater

A technology of ammonia nitrogen wastewater and treatment method, which is applied in the field of high concentration ammonia nitrogen wastewater treatment, can solve the problems that high ammonia nitrogen wastewater cannot be effectively removed, ammonia nitrogen wastewater has not been further studied, and the proportion of activated sludge is low, so as to reduce excess sludge The effect of high volume, high value-added products, and low sludge disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

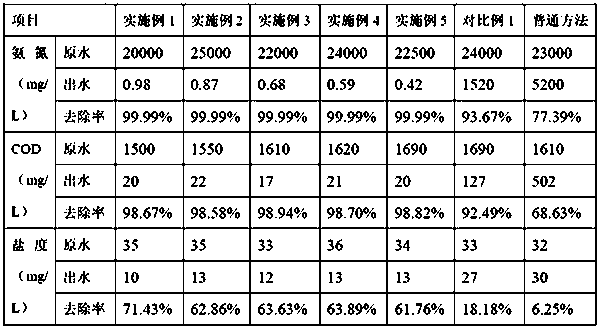

Examples

Embodiment 1

[0032] A treatment method for high-concentration ammonia nitrogen wastewater, comprising the following steps:

[0033] S1. Filtration: pass high-concentration ammonia nitrogen wastewater through a sieve, the sieve is a 100-mesh sieve, to obtain particle-free wastewater, and the ammonia nitrogen value of the wastewater is 20000mg / L;

[0034] S2. Salinization: heat the particle-free wastewater in step S1 to 70°C, add hydrochloric acid at a volume ratio of 1:1.2, the concentration of hydrochloric acid is 40g / L, stir and react at a stirring speed of 500r / min, and drop to room temperature. Precipitate ammonium chloride crystals, filter, and retain the solids, which can be used as agricultural fertilizers, and the filtrate is medium-concentration ammonia nitrogen wastewater;

[0035]S3. Impurity removal: Heat the medium-concentration ammonia nitrogen wastewater in step S2 to 70°C-80°C, add NaOH to adjust the pH to 7.8, produce a large amount of precipitation, filter, the solid is me...

Embodiment 2

[0039] A treatment method for high-concentration ammonia nitrogen wastewater, comprising the following steps:

[0040] S1. Filtration: pass high-concentration ammonia nitrogen wastewater through a sieve, the sieve is 100 mesh or 150 mesh, to obtain particle-free wastewater, the ammonia nitrogen value of the wastewater is 25000mg / L;

[0041] S2. Salinization: heat the particle-free wastewater in step S1 to 80°C, add hydrochloric acid at a volume ratio of 1:1.2, the concentration of hydrochloric acid is 40-50g / L, stir and react, and the stirring speed is 700r / min, down to At room temperature, ammonium chloride crystals are precipitated, filtered, and the solids are retained for use as agricultural fertilizers. The filtrate is medium-concentration ammonia nitrogen wastewater;

[0042] S3. Impurity removal: Heat the medium-concentration ammonia-nitrogen wastewater in step S2 to 80°C, add NaOH to adjust the pH to 8.5, produce a large amount of precipitation, filter, the solid is me...

Embodiment 3

[0046] A treatment method for high-concentration ammonia nitrogen wastewater, comprising the following steps:

[0047] S1. Filtration: pass high-concentration ammonia nitrogen wastewater through a sieve, the sieve is a 150-mesh sieve, to obtain particle-free wastewater, and the ammonia nitrogen value of the wastewater is 22000mg / L;

[0048] S2. Salinization: heat the particle-free wastewater in step S1 to 72°C, add hydrochloric acid at a volume ratio of 1:1.2, the concentration of hydrochloric acid is 42g / L, stir and react at a stirring speed of 550r / min, and drop to room temperature. Precipitate ammonium chloride crystals, filter, and retain the solids, which can be used as agricultural fertilizers, and the filtrate is medium-concentration ammonia nitrogen wastewater;

[0049] S3. Impurity removal: Heat the medium-concentration ammonia nitrogen wastewater in step S2 to 72°C, add NaOH to adjust the pH to 7.8-8.5, produce a large amount of precipitation, filter, the solid is me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com