Method for breaking barrel to make barreled solidified waste oil go out

A technology of waste oil and barrel breaking, applied in packaging, transportation and packaging, unsealing of objects, etc., can solve the problems of increasing oil-water separation, breaking through the bottom of the barrel, hurting people, and being easily burned by steam, so as to meet production requirements and improve purification. The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

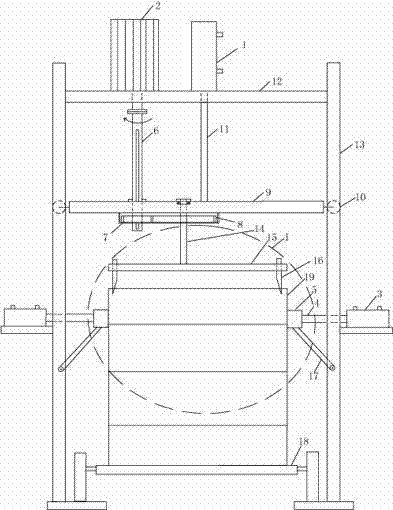

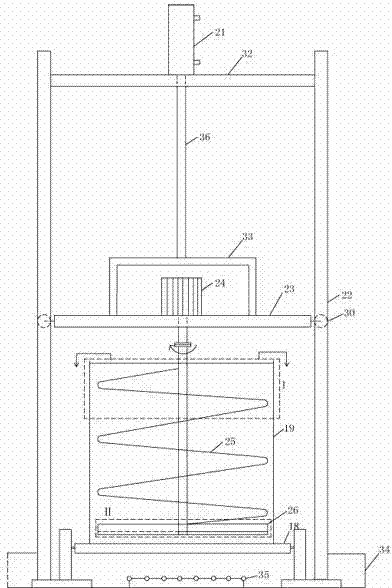

[0023] In the following, the barrel-broken oil extraction method of coagulated solid waste oil in barrels of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0024] The barrel-broken solidified waste oil extraction method of the present invention first uses a barrel breaker to completely break the barrel cover along the edge of the barrel cover, and after removing the barrel cover, the oil barrel is sent to the barrel discharge machine, and the oil barrel is removed by a spiral twister with a scraper. Dragon discharges most of the condensed waste oil, and then transports the oil drum to the turning machine, flips it to the vibrating machine and dumps it, and then sends the poured oil drum to the drying room to make the oil adhered to the wall of the drum through indirect steam heating. A small amount of waste oil is melted and recycled, and finally the empty barrel is sent to the yard; the specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com