Preparation of novel boric acid functionalized macroporous resin and application of novel boric acid functionalized macroporous resin in selective adsorption of stevioside

A technology of macroporous resin and stevioside, which is applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problem of limited effect of separating STV, and achieve improved separation and purification, high adsorption capacity, and high selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] see figure 1 Shown, the present invention is a kind of preparation method of stevioside selective adsorption material, comprises the following steps:

[0040] Step S01: preparing acrylic macroporous resin by suspension polymerization;

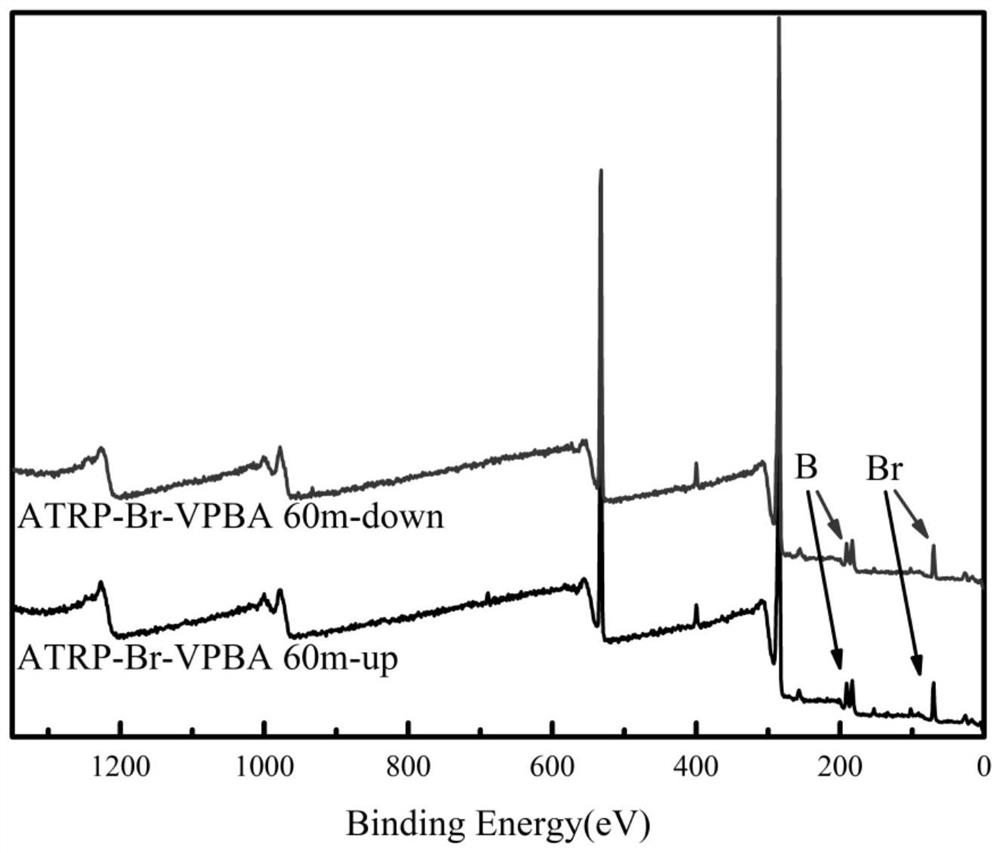

[0041] Step S02: introducing the acrylate macroporous resin into the initiator BIBB to form brominated active sites on the surface of the acrylate macroporous resin to obtain the initiator functionalized resin;

[0042] Step S03: adding the initiator functionalized resin into the polymerization solution, and grafting the brominated active sites on the surface of the acrylate macroporous resin to obtain a steviol glycoside selective adsorption material.

[0043] Preferably, in step S01, the composition of the acrylic macroporous resin includes by weight components: acrylic esters-1.072 parts, GDMA-5.555 parts, ethyl acetate-6.627 parts, AIBN-26.506 parts and HPMC-0.133 parts ; wherein acrylates are monomers, GDMA is a crosslinking agent...

Embodiment 1

[0063] This example provides the application of the above stevioside selective adsorption material in the adsorption of stevioside.

[0064] First weigh 0.1g of stevioside selective adsorption material and place it in the conical flask, then pipette 50ml of the prepared stevioside solution (STV: RA=1:1) with a concentration of 6g / L, and add it to the conical flask , the Erlenmeyer flask was sealed, and the Erlenmeyer flask was placed in a constant temperature shaking box, oscillating at a constant temperature of 30°C, and the equilibrium adsorption amount Qe of stevioside was calculated by the following formula:

[0065]

[0066] In the formula, Qe is the equilibrium adsorption capacity of selective adsorption material to stevioside, the unit is mg / g; V is the volume of stevioside solution, the unit is mL; C 0 is the initial concentration of stevioside solution, in g / L; Ct is the concentration of stevioside in the supernatant after adsorption equilibrium, in g / L; m is the m...

Embodiment 2

[0072] Such as figure 2 As shown, the infrared spectrum of the original hydroxyl-containing acrylate resin and the grafted resin microspheres obtained in this embodiment can be seen in the infrared spectrum, and in the boric acid functionalized grafted resin spectrum, 1350cm -1 A new B-O bond characteristic absorption peak appeared at , which proved that VPBA was successfully grafted to the surface of acrylic resin;

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com