Ship efficient self-cooling method free of sea water pump

A self-cooling and high-efficiency technology, applied in the direction of ships, ship propulsion, ship parts, etc., can solve the problems of not easy to use, low grade, loss, etc., and achieve the effect of improving endurance, reducing energy consumption and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

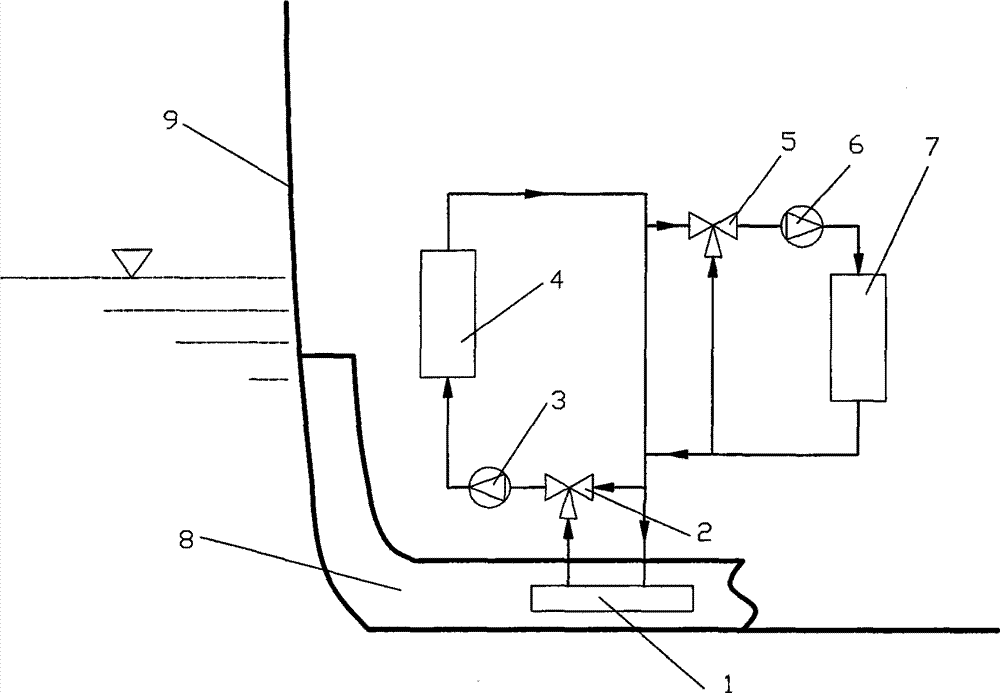

Method used

Image

Examples

Embodiment Construction

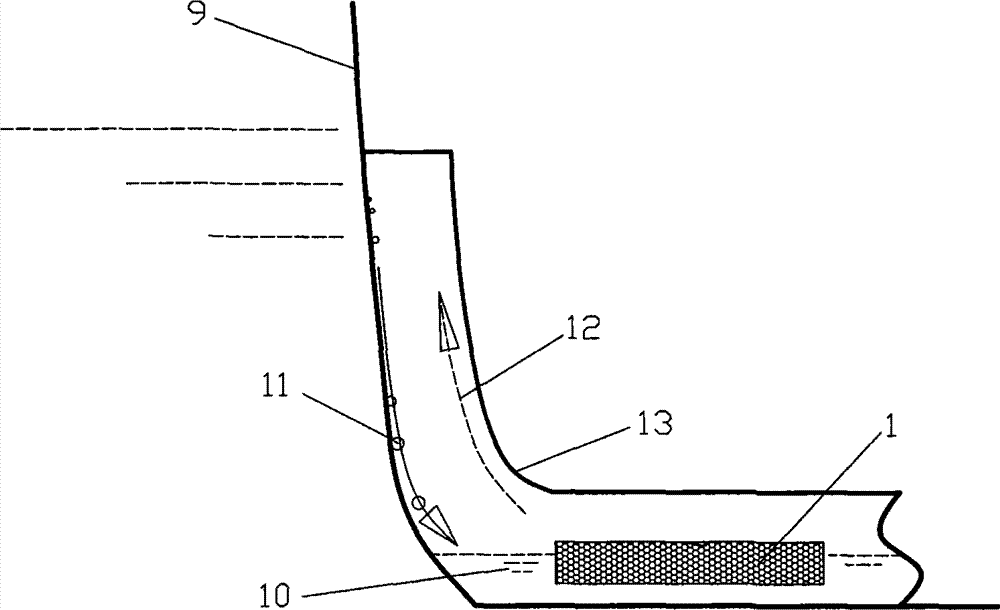

[0018] as attached figure 2 As shown, according to the actual calorific value of the ship system, the outboard seawater temperature is 32°C and the ship speed is 5m / s. The required heat exchange area of the hull; water and nanofluids and other low-boiling point fluids are selected as the working medium 10, and the amount of the required working medium 10 is calculated according to the heat transfer. The evaporative heat exchanger 1; the surface of the high-efficiency evaporative heat exchanger 1 in contact with the working medium 10 is processed into a hydrophilic surface with a capillary microstructure, and the inner surface of the hull 9 used for heat exchange is processed into a superhydrophobic surface with a microstructure . Make full use of the ship's double bottom and side chords, select materials with poor thermal conductivity as the heat insulation cover plate 13, place the working fluid 10 and the high-efficiency evaporative heat exchanger 1 at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com