Argon arc welding machine lower electrode

A technology of argon arc welding machine and electrode, which is applied in the direction of arc welding equipment, welding medium, electrode characteristics, etc., can solve the problems that are not involved in the structure of the lower electrode of argon arc welding machine, and are not suitable for argon arc welding machine, so as to eliminate the direct Effect of cooling and nozzle airflow on the weld seam, configuration and maintenance cost saving, low heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

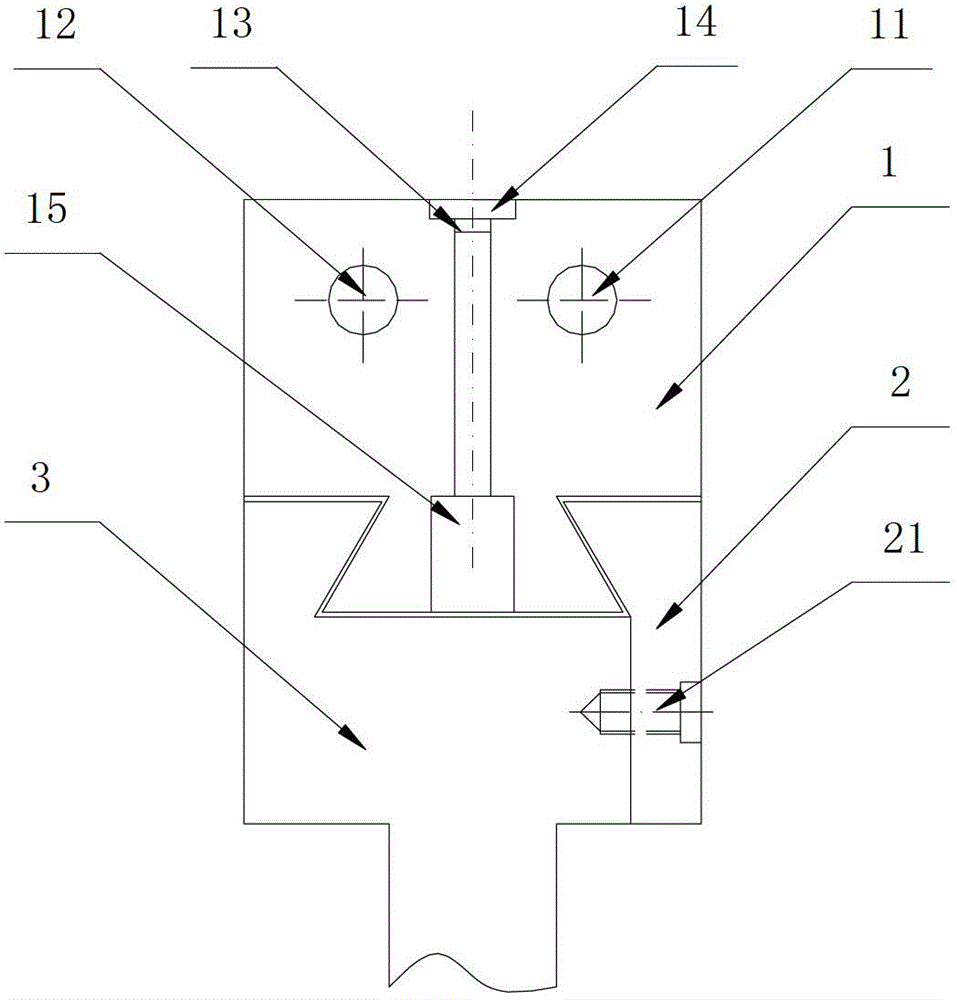

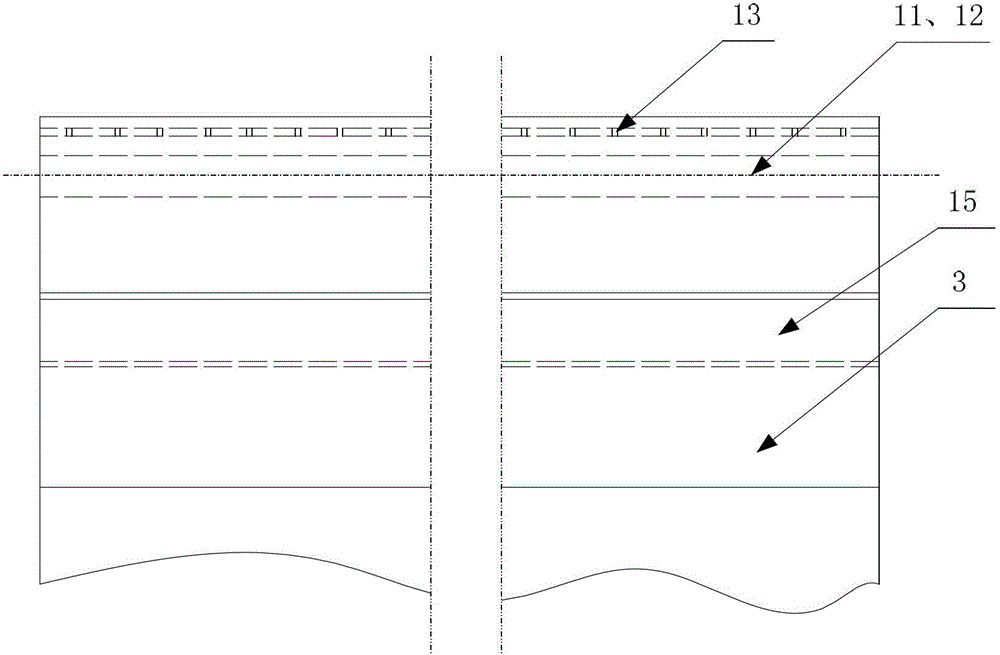

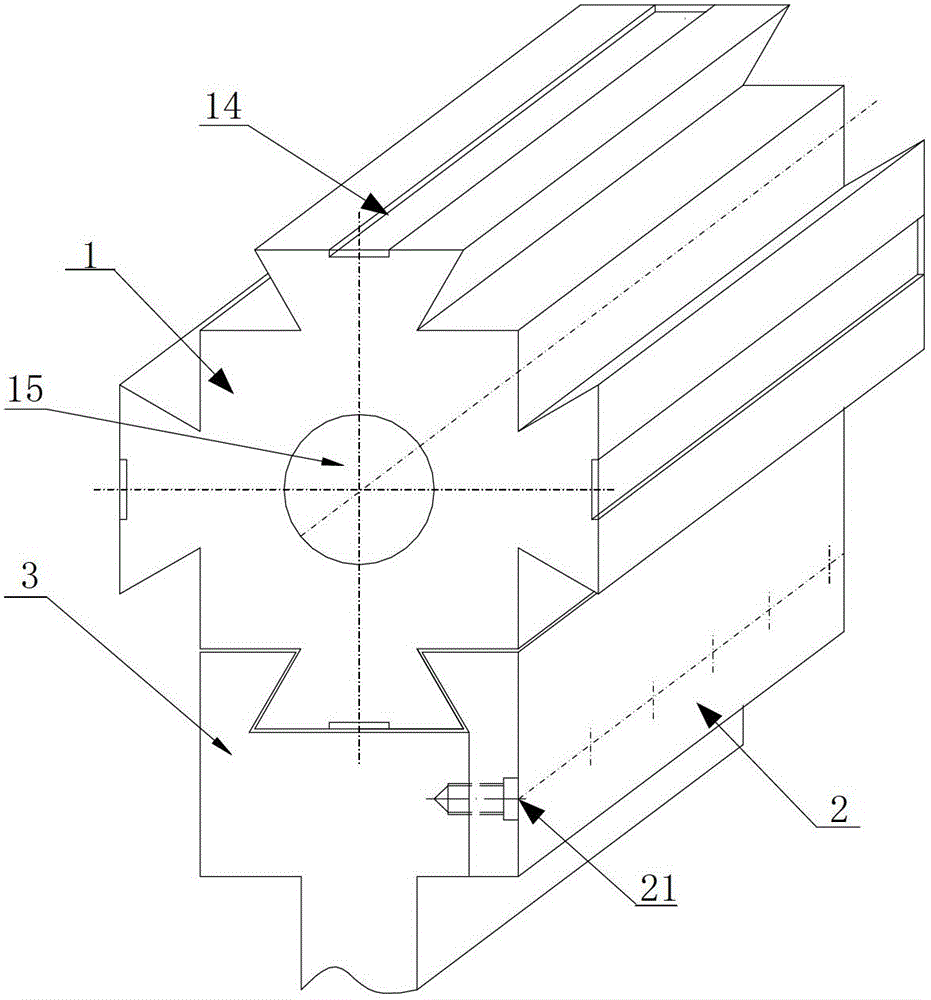

[0035] An embodiment of the lower electrode of the argon arc welding machine of the present invention is as image 3 and Figure 4 As shown, the lower electrode 1 is fixed on the wedge-shaped groove of the lifting seat 3 of the argon arc welding machine through the pressure plate 2 and the fastener 21, and the length of the lower electrode 1 is consistent with the length of the welding workpiece. exist image 3 and Figure 4 In the shown embodiment, the lower electrode 1 adopts a polygonal wedge-shaped structure with four working surfaces, and each working surface is processed into a wedge-shaped structure, which cooperates with the wedge-shaped groove of the lifting seat 3, and passes through the pressing plate 2 and the wedge-shaped structure. The fastener 21 is fixed on the wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com