Constipation-relieving drink granules and preparation method thereof

A beverage and granule technology, which is applied in the field of beverage granules for relieving constipation and its preparation, can solve the problems of destroying body balance, disease breeding, and aggravation of the disease, and achieve the effects of reducing residence time, promoting intestinal peristalsis, and relieving constipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

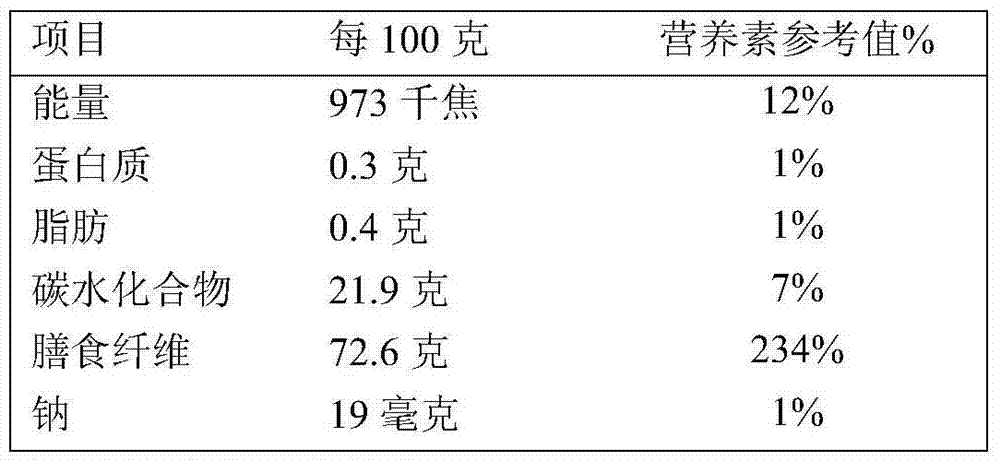

Image

Examples

Embodiment 1

[0026] Embodiment 1: Weigh each raw material component according to the following mass ratio.

[0027] 15 parts polydextrose;

[0028] 15 parts of fructooligosaccharides;

[0029] 18 parts of inulin;

[0030] 6 parts pineapple juice powder;

[0031] 8 servings of mango juice powder;

[0032] 7 parts of pumpkin pulp powder;

[0033] 0.5 parts of xanthan gum;

[0034] 2.5 parts of konjac gum;

[0035] 5 parts of erythritol;

[0036] Mannitol 3 parts.

[0037] Fully dissolve the above-mentioned raw material components that have been weighed in water to form a 25wt% solution, and then use a buffer of sodium hydrogen phosphate, sodium dihydrogen phosphate and sodium hydroxide (the mass ratio of the three is 0.5:0.5:99) The solution was adjusted to pH 4. Then, use three-effect concentration to concentrate the solution to 68wt%. It is carried out at a vacuum degree of -0.08MP; the three-effect concentration is carried out at a temperature of 42°C and a vacuum degree of not ...

Embodiment 2

[0038] Embodiment 2: Weigh each raw material component according to the following mass ratio.

[0039] 22 parts of polydextrose;

[0040] 15 parts of fructooligosaccharides;

[0041] 21 parts of inulin;

[0042] 8 parts of pineapple juice powder;

[0043] 6 parts of mango juice powder;

[0044] 7 parts of pumpkin pulp powder;

[0045] 1.5 parts of xanthan gum;

[0046] Konjac gum 2 parts;

[0047] 7 parts of erythritol;

[0048] Mannitol 2 parts.

[0049] Fully dissolve the above-mentioned raw material components that have been weighed in water to form a 30wt% solution, and then use a buffer of sodium hydrogen phosphate, sodium dihydrogen phosphate and sodium hydroxide (the mass ratio of the three is 0.5:0.5:99) The pH of the solution was adjusted to 4.5. Then, use three-effect concentration to concentrate the solution to 73wt%. The concentration conditions are as follows: the first-effect concentration is carried out at a temperature of 81°C and a vacuum not lower th...

Embodiment 3

[0050] Embodiment 3: Weigh each raw material component according to the following mass ratio.

[0051] 18 parts of polydextrose;

[0052] 18 fructooligosaccharides;

[0053] 25 servings of inulin;

[0054] 6 servings of pineapple juice powder;

[0055] 10 servings of mango juice powder;

[0056] 9 parts of pumpkin pulp powder;

[0057] 1 part xanthan gum;

[0058] 3 parts of konjac gum;

[0059] 7 parts of erythritol;

[0060] 3 servings of mannitol.

[0061] The above-mentioned raw material components that have been weighed are fully dissolved in water to form a solution of 27 wt %. The solution was adjusted to pH 5. Then, the solution was concentrated to 70wt% by three-effect concentration, and the concentration conditions were: the first-effect concentration was carried out at a temperature of 78°C and a vacuum degree not lower than -0.06MP; the second-effect concentration was carried out at a temperature of 63°C and not lower than It is carried out under the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com