Photovoltaic conversion element and method of manufacture thereof

A technology for photoelectric conversion components and manufacturing methods, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of insufficient practicability, photoelectric conversion efficiency, insufficient durability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

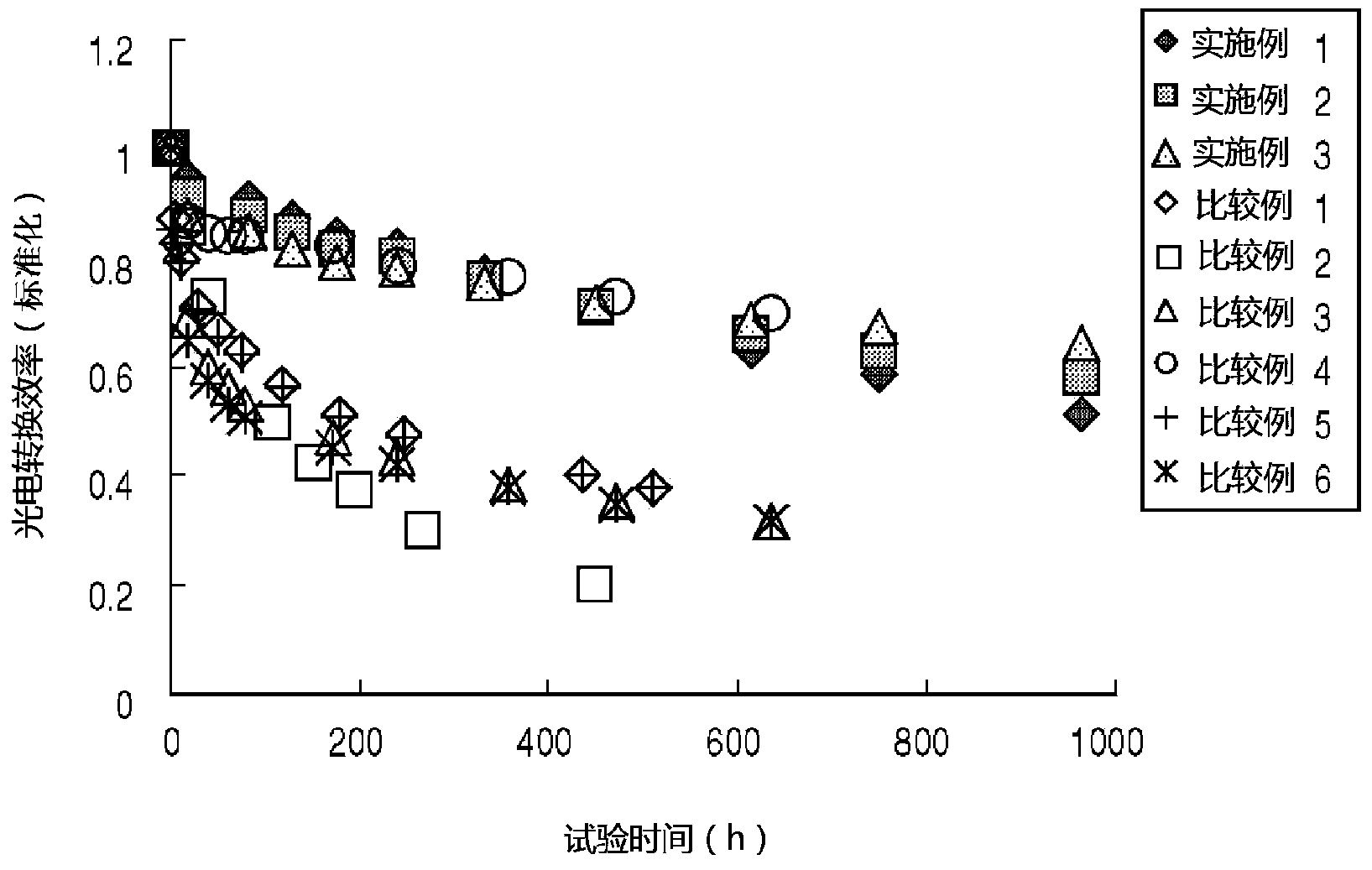

Embodiment 1

[0116]

[0117] The glass substrate (surface resistance value 15Ω / □) obtained by forming a film of ITO by a sputtering method was washed to form an electrode for a negative electrode (electron output electrode).

[0118]

[0119] (1) Formation of electron transport layer

[0120] The electron transport layer was produced by the solution coating method. Specifically, zinc acetate dihydrate (manufactured by Aldrich) was dissolved in 2-methoxyethanol at a concentration of 20 mg / ml, and then monoethanolamine (55 μl / ml) was added to prepare a solution. The solution was spin-coated on the ITO for the negative electrode at 2000 rpm (30 seconds), and the heat treatment was performed on a hot plate at 120° C. for 5 minutes to form an electron transport layer (see Table 1). The thickness of the electron transport layer after the heat treatment was 30 nm.

[0121] (2) Formation of the energy regulation layer at the lower end of the conduction belt

[0122] Cesium carbonate (manufactured by Ald...

Embodiment 2

[0134] The manufacturing method of the photoelectric conversion element of Example 2 is the same as that of Example 1, except that the heat treatment temperature when forming the electron transport layer is 300°C. The manufacturing method of the photoelectric conversion element of Example 3 is the same as that of Example 1, except that ZnMgO is prepared as the electron transport layer as follows.

[0135]

[0136] Zinc acetate dihydrate (manufactured by Aldrich) and zinc acetate tetrahydrate (manufactured by Aldrich) were dissolved in 2-methoxyethanol at a concentration of 15mg / ml and 5mg / ml respectively, and then monoethanolamine (5.5μl / ml) was added. , Stir for 2 hours. The above-mentioned ITO for negative electrode was spin-coated with the above-mentioned solution at 2000 rpm (30 seconds) and heat-treated at 300°C for 5 minutes on a hot plate to form an electron transport layer. The thickness of the electron transport layer after the heat treatment was 30 nm.

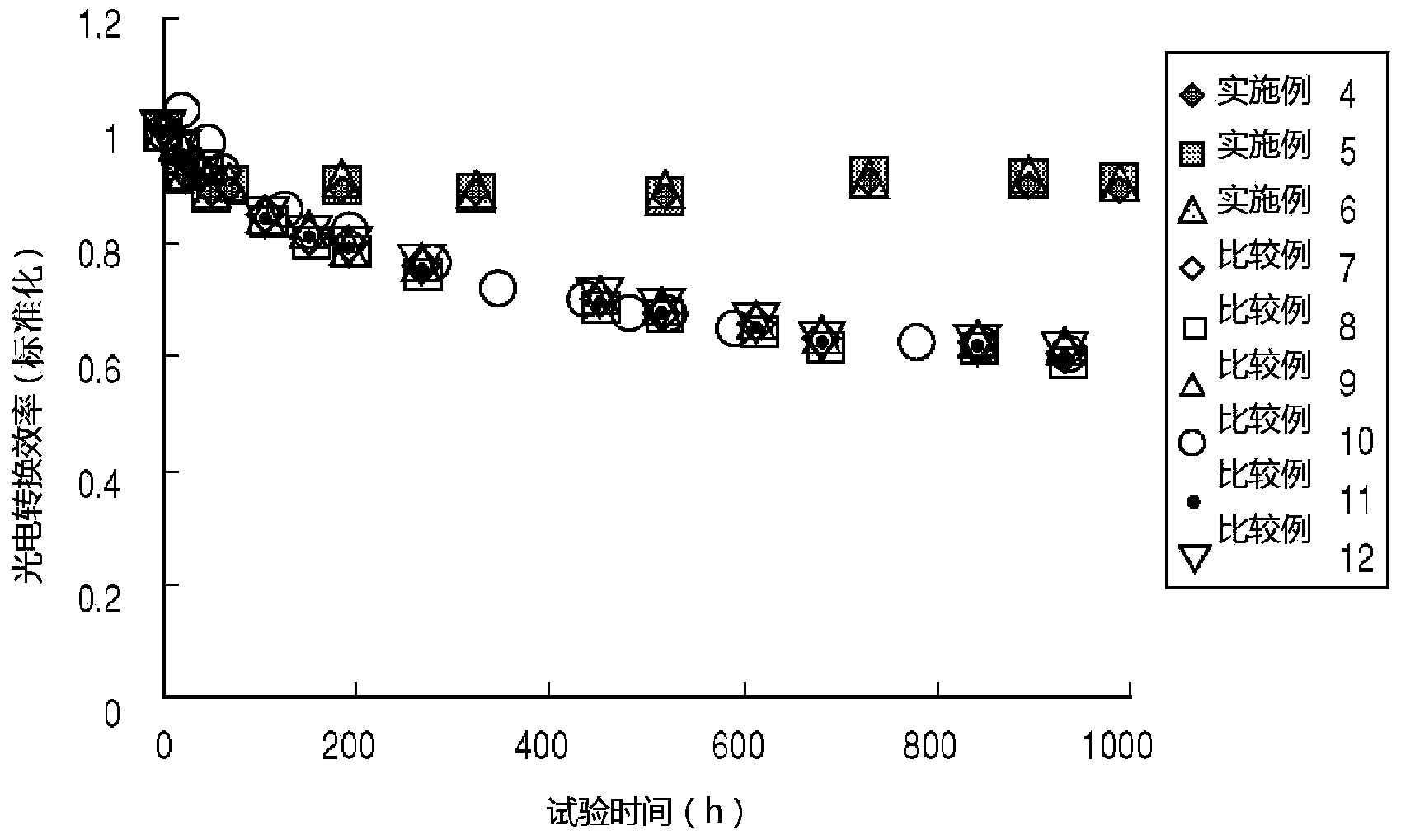

Embodiment 4~6

[0138] The UV blocking film (manufactured by King Works Co., Ltd., KU-1000100, with a transmittance of 1% or less in the wavelength range of 370 nm or less) was pasted on the negative glass substrate, except that it was the same as Examples 1 to 3, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com