Cable core automatic straightening device

A cable core, automatic technology, applied in the direction of connecting/terminating cable equipment, etc., can solve the problems of low, time-consuming and labor-intensive efficiency of the cable core, and achieve the effect of convenient and flexible operation, fast processing speed and good straightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

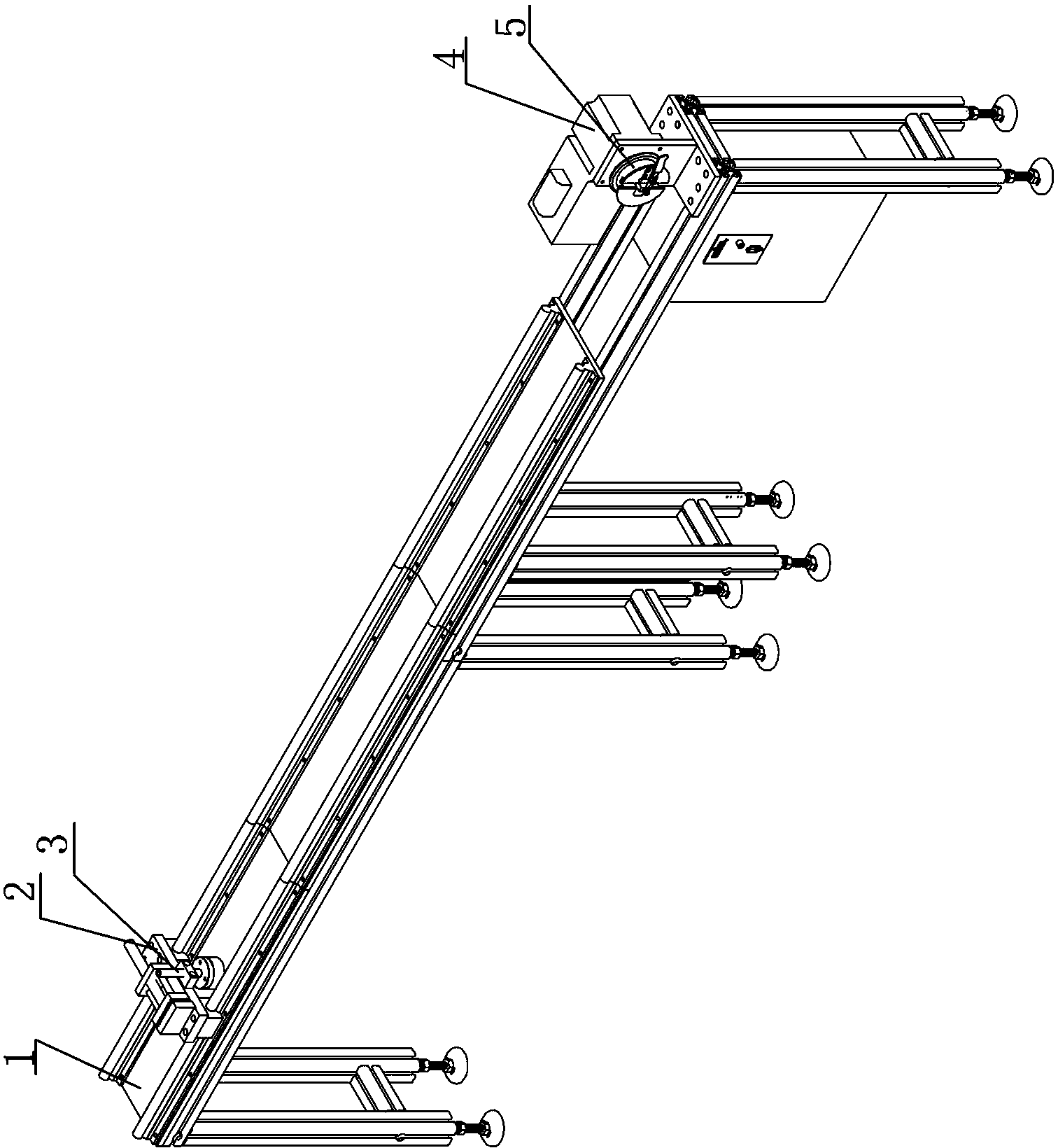

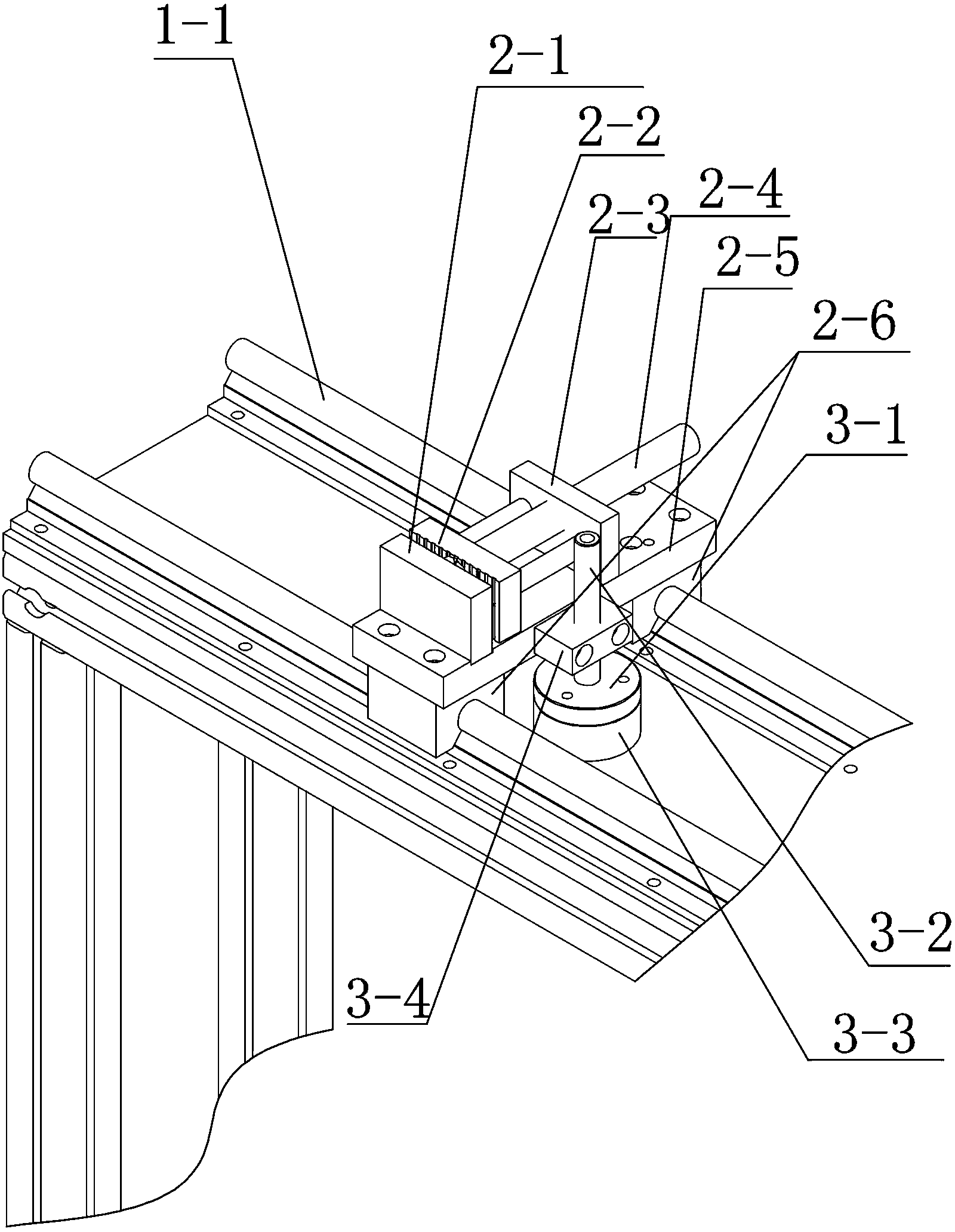

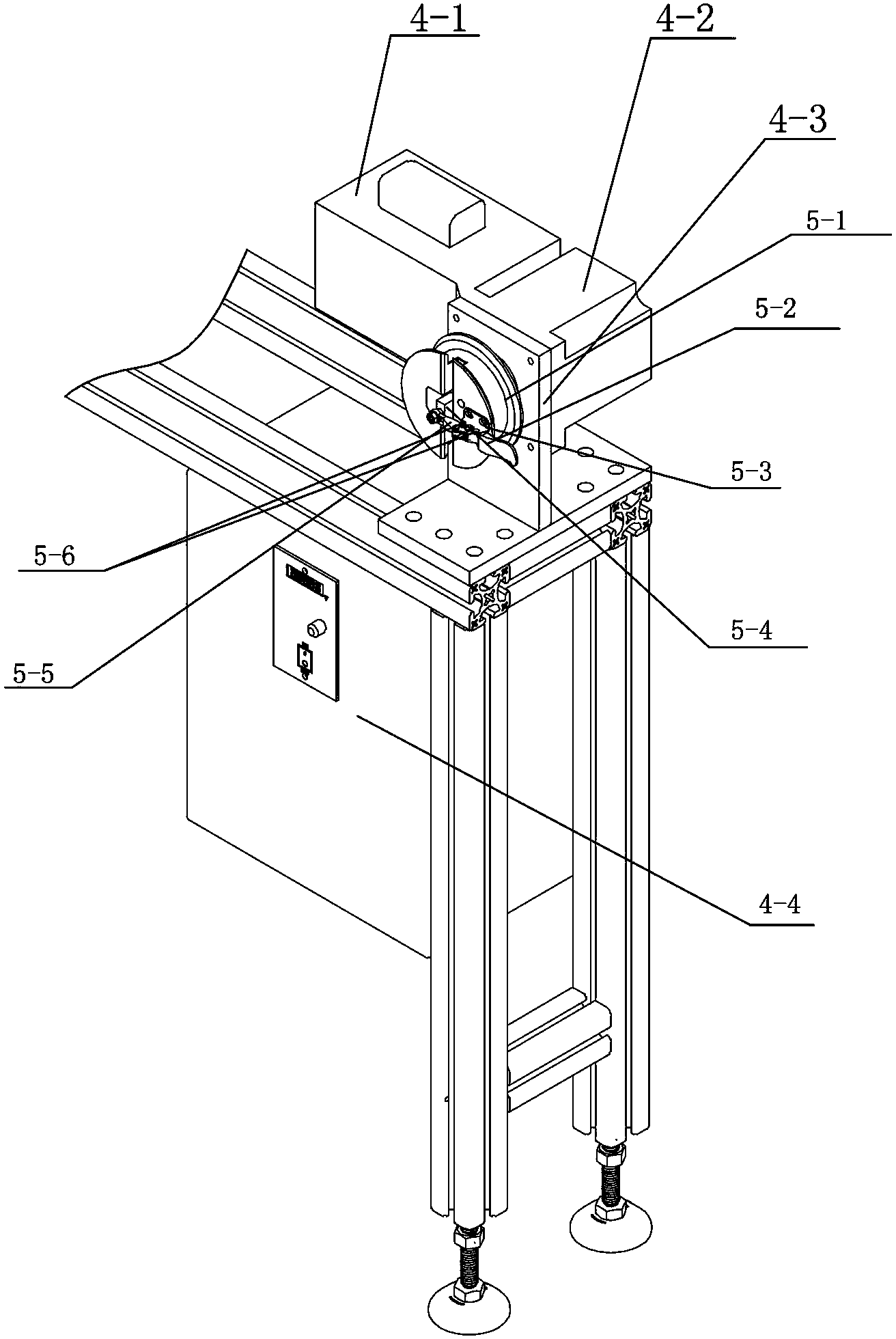

[0015] The following will be described in detail in conjunction with the accompanying drawings: as shown in the figure: the frame 1 is a rectangular frame structure that can be spliced in sections, and a linear guide rail 1-1 is arranged on the upper part of the frame 1; the sliding seat part 2 includes a sliding seat 2- 6, and the sliding plate 2-5 fixed on the sliding seat 2-6 and the cable head fixing device installed on the sliding plate 2-6; the cable head fixing device includes a fixed clamping plate 2-1 and a movable clamping plate 2-2 , fixed wire motherboard 2-3, leading screw 2-4, fixed clamping plate 2-1 and fixed wire motherboard 2-3 are fixed on the slide plate 2-5, fixed wire motherboard 2-3 and leading screw 2- 4 form a lead screw pair, one end of the lead screw 2-4 is fixed with a movable clamping plate 2-2; the power transmission part includes a torque motor 4-2, a right-angle reducer 4-2, a torque regulator controller 4-4, and a right-angle reducer 4-2 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com