Electric vehicle power battery pack temperature control system based on heat pipes

A technology for power battery packs and electric vehicles, applied in battery pack components, batteries, secondary batteries, etc., can solve the effect of battery pack temperature distribution uniformity, air short-circuit, the number of single cells, and thermal management effect limitations, etc. problem, to achieve the effect of obvious heating and cooling effect, good ability to protect the battery pack, and good thermal management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

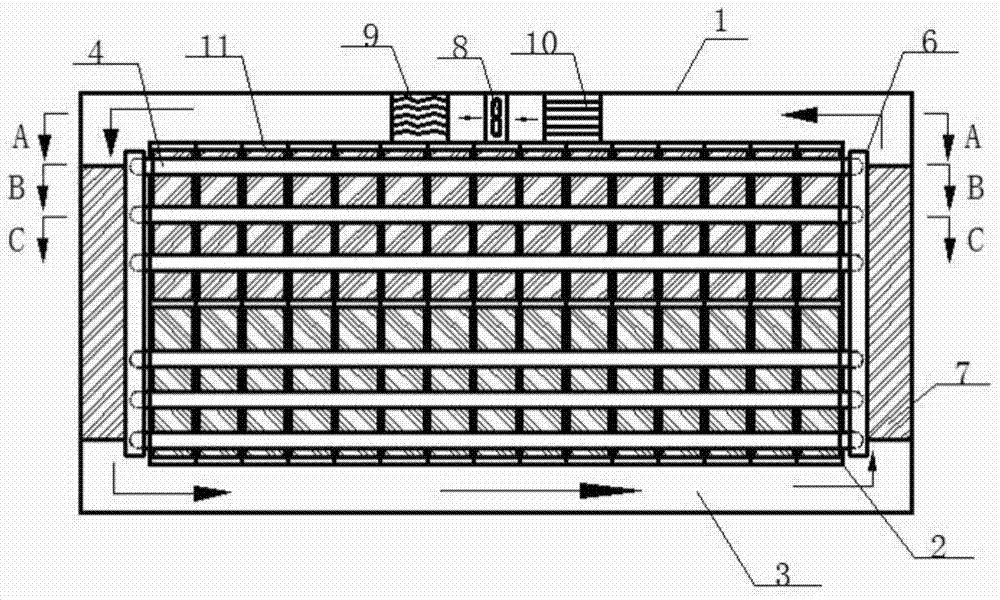

[0045] See figure, figure 2 , image 3 , Figure 4 with Figure 5 , the main cross-sectional view of the electric vehicle power battery pack temperature control system in this embodiment is as follows figure 1 As shown, the battery pack temperature control box 1 is an airtight box, which contains a closed battery group compartment 2 inside. The length and height of the battery pack compartment 2 are smaller than the battery pack box 1, but the width and temperature The width of the control box 1 is the same, and there is an annular heat exchange compartment 3 between the battery group compartment 2 and the battery pack temperature control box 1, and the annular heat exchange compartment 3 is formed on the top and bottom surfaces of the battery group compartment 2 , and along the two end faces of the battery group warehouse 2 in the length direction, there is a circulating heat transfer medium in the annular heat exchange warehouse 3 .

[0046] Such as figure 1 , figure 2...

Embodiment 2

[0055] see Image 6 In this embodiment, the heat transfer medium in the annular heat exchange chamber 3 is liquid, and the heater 10, the electromagnetic pump 13 and the evaporator 9 are arranged in series along the flow direction of the fluid. see Figure 7 In this embodiment, the back of the heat dissipation substrate 6 is arranged with staggered heat dissipation studs 14 . In this embodiment, 10×10 heat dissipation studs 14 are arranged in a staggered manner on the back of the heat dissipation substrate 6 .

[0056] The rest of the structure is the same as in Embodiment 1, and the working principle is consistent.

Embodiment 3

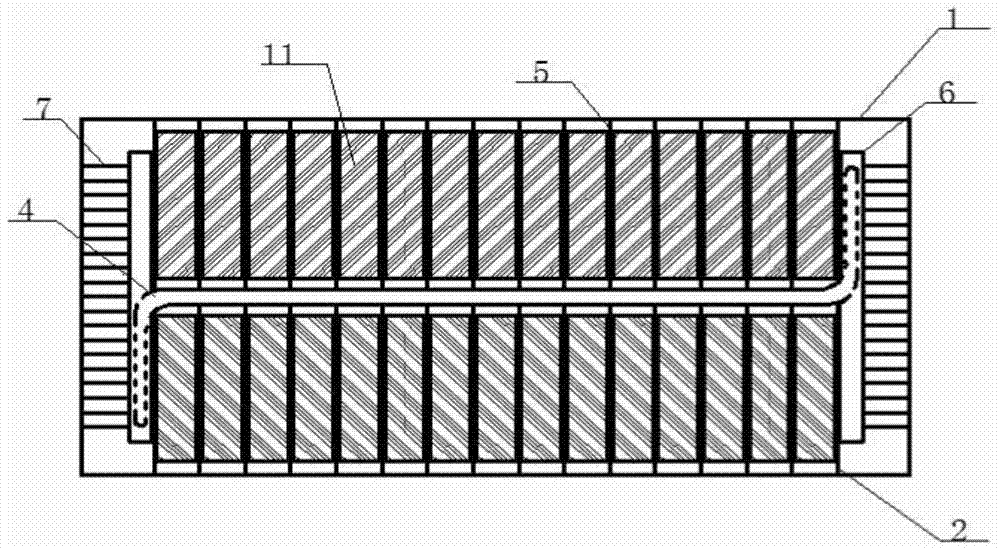

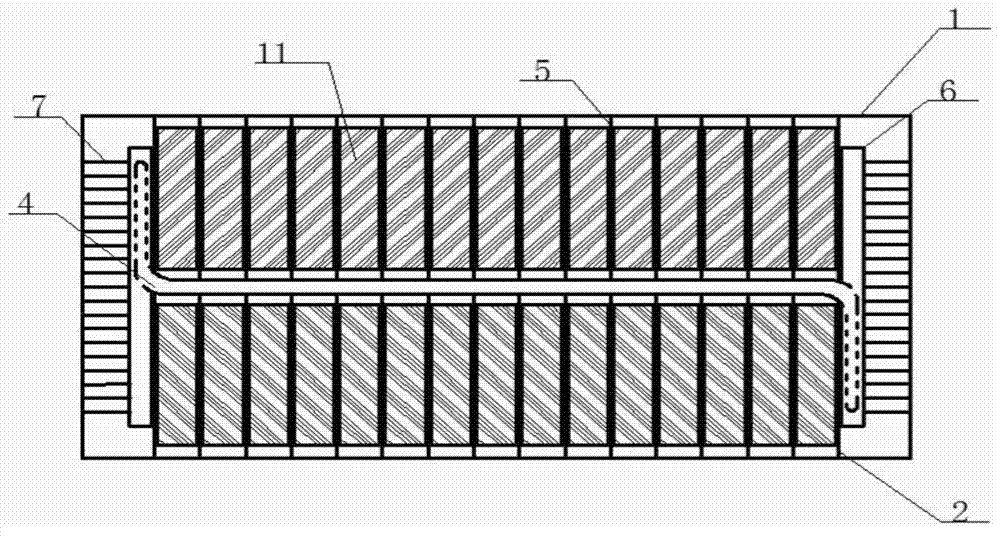

[0058] see Figure 8 with Figure 9 In this embodiment, a cylindrical single battery 11 is used, and the single battery 11 is installed horizontally between the insulating heat sinks 5 , and the insulating heat sink 5 is bonded to the two terminal surfaces of the single battery 11 . In this embodiment, 14 layers of single cells are arranged between two adjacent insulating fins 5 , each layer has 12 single cells 11 , and the distance between the single cells 11 is 2 mm.

[0059] The rest of the structural design is the same as in Embodiment 1, and the working principle is consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com