A test method for low-voltage control mode of converter valve control equipment

A technology for controlling equipment and control modes, applied in the direction of electronic circuit testing, etc., can solve the problems of inaccurate testing, inability to directly control triggering and monitoring, complicated testing process, etc., and achieve the effect of early detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

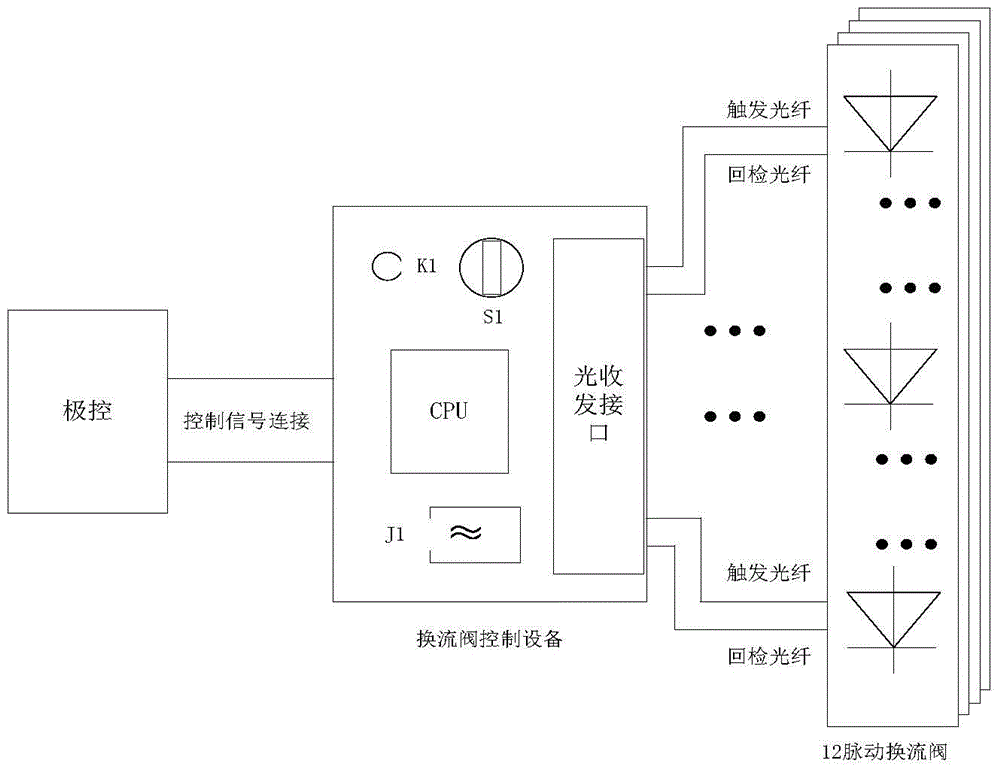

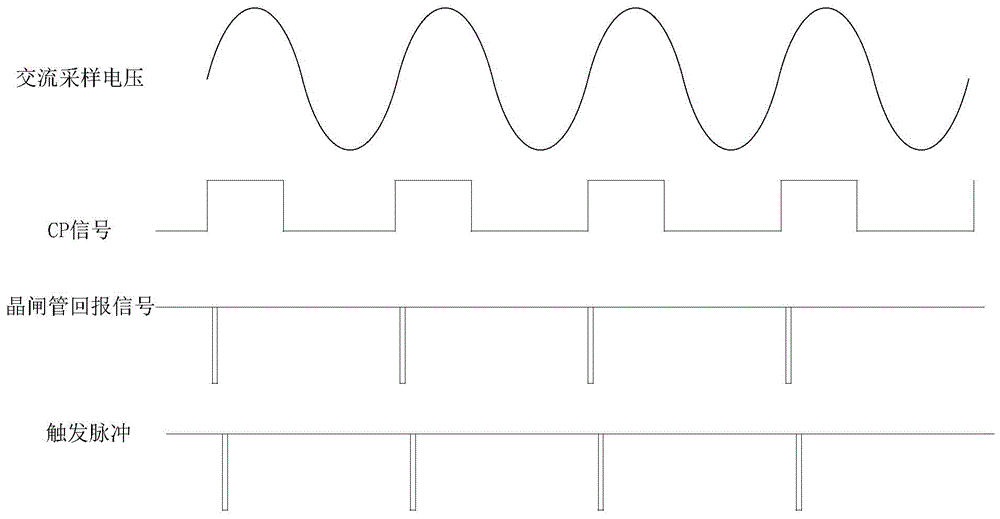

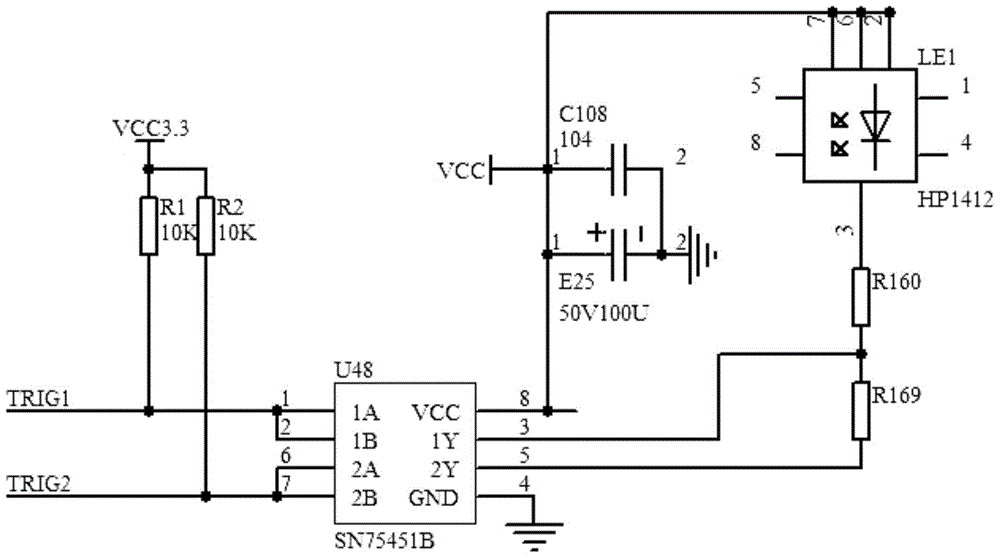

[0020] When the normal mode is running, when the valve control system receives the unlocking signal of the extreme control and is valid, the control enters the unlocking state. In the unlocked state, two conditions need to be met for the valve control device to send trigger pulses to the thyristor control board. One is to receive the CP signal (trigger control pulse signal) from the extreme control, and the other is to receive the thyristor forward voltage establishment signal from the thyristor control board. According to different voltage levels, the number of thyristors in a single valve is different. The valve control system generally receives a return signal from more than 70% of the thyristors in a single valve (specific projects, different parameters), and then determines that the forward voltage of the valve is established. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com