Reinforced concrete pole

A technology of reinforced concrete and concrete layers, applied in wind power generation, building types, buildings, etc., can solve the problems of pole body damage, shorten the service life of poles, and easily cause pole collapse, etc., and achieve good corrosion resistance, high strength, and structure simple effect design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below we describe in further detail the specific implementation cases of the present invention in conjunction with the accompanying drawings:

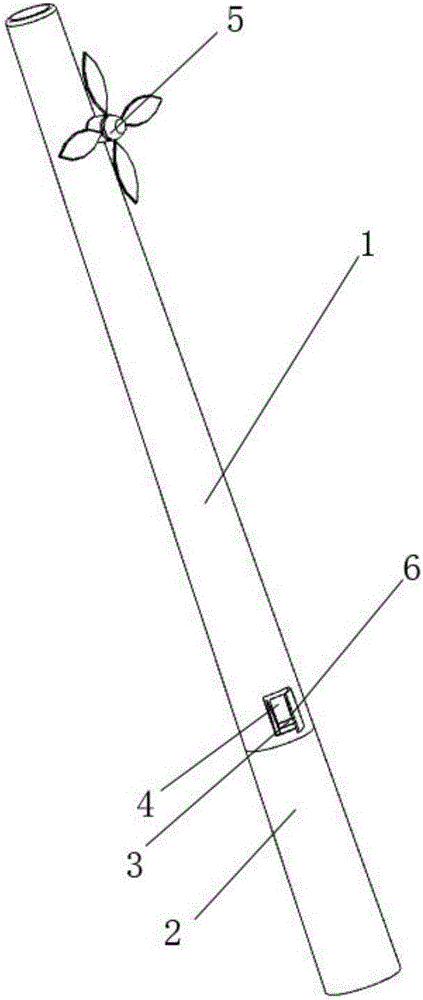

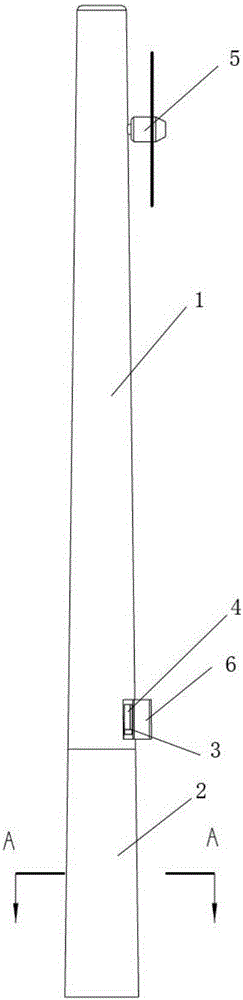

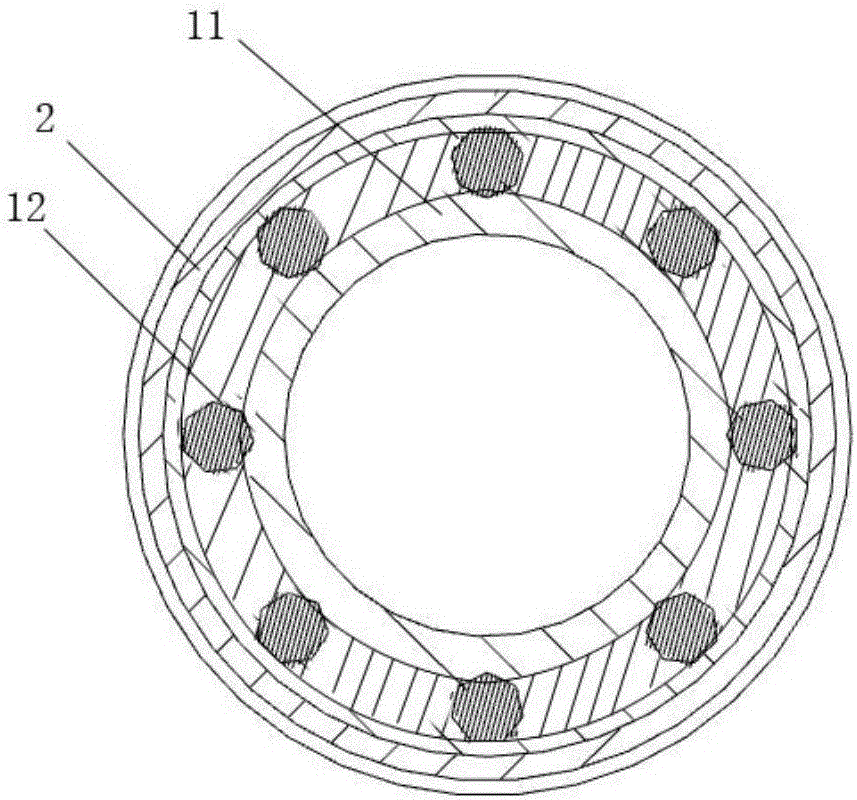

[0018] Such as figure 1 As shown, a reinforced concrete pole includes a pole body 1, a detection and alarm system and a ceramic layer 2, and the detection and alarm system is arranged on the pole body 1; as image 3 As shown, the rod body 1 includes a hollow concrete layer 11 and a reinforcing steel structure layer 12, the concrete layer 11 is internally provided with a reinforcing steel structure layer 12; the lower part of the rod body 1 is wrapped with a layer of ceramic layer 2; Such as Figure 4 As shown, the circular array inside the ceramic layer 2 is provided with engaging parts 21, and there are 12 engaging parts 21 in three rows; the height of the ceramic layer 2 is 1.0m-2.0m. The detection and alarm system includes an angle sensor 3, an alarm device 4, and a wind power generation device 5. The angle sensor 3 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com