Gas chromatography/mass spectrometry (GC/MS) method for detecting dimethyl fumarate in food additive

A technology of dimethyl fumarate and food additives, applied in the field of food additives, can solve problems such as damage to the intestinal tract, visceral allergies, etc., and achieve the effects of easy operation, simple pretreatment, and short time-consuming method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A gas chromatography / mass spectrometry detection method for dimethyl fumarate in a food additive, comprising the following steps:

[0038] 1) Accurately weigh 0.2 g of the food additive sample, place it in a 25 mL Erlenmeyer flask, add 15 mL of dichloromethane extract with an internal standard concentration of 2 μg / mL, and perform ultrasonic extraction at room temperature for 15 min;

[0039] 2) The extract is filtered through an organic phase filter membrane with a pore size of 0.45 μm, and then detected by gas chromatography / mass spectrometry.

[0040] Gas chromatography / mass spectrometry analysis conditions: use DB-5MS (30m×0.25mm×0.25μm) capillary column for separation, inlet temperature: 250°C, injection volume: 1μL, split ratio: 1:10, column flow: 1mL / min, heating program: hold at 80°C for 2min, rise to 200°C at 5°C / min, hold for 2min; mass spectrometry conditions: electron ionization source (EI), ionization voltage: 70eV, ion source temperature: 230°C; quadrupole...

Embodiment 2

[0044] Same as Example 1, except that 0.1 g of the sample was weighed into a 10 mL Erlenmeyer flask, 5 mL of the extract was added and ultrasonicated for 15 min, and the extract was filtered through a 0.22 μm organic phase membrane for measurement. To obtain the content of dimethyl fumarate in the sample, add a standard sample of dimethyl fumarate to a certain food additive sample with known content, and measure the content of dimethyl fumarate in three levels of low, medium and high. Methyl ester content value. Three samples were measured in parallel for each level, and the average value was used to calculate the recovery rate of standard addition. The test results are shown in Table 1:

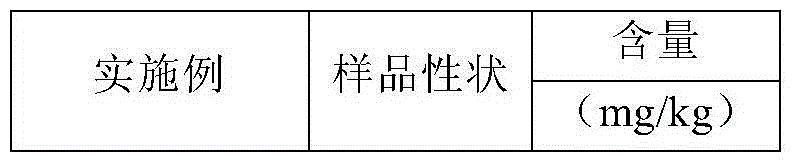

[0045] The recovery rate result of table 1 method

[0046]

[0047]The results in Table 1 show that the recovery rate of dimethyl fumarate is 95.86%-102.46%, indicating that the recovery rate of the method of the present invention is relatively high and meets the requirements of quantit...

Embodiment 3

[0050] A gas chromatography / mass spectrometry detection method for dimethyl fumarate in a food additive, comprising the following steps:

[0051] According to the sample processing, extraction, and analysis methods in Example 1, weigh 0.3g extract-like food additive sample into a 25mL Erlenmeyer flask, add 15mL extract and sonicate for 15min, and then filter the extract through a 0.45 μm organic phase membrane for determination.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com