Automatic testing machine of gas cylinder hydrostatic test

An automatic testing machine and hydrostatic test technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and using liquid/vacuum to measure liquid tightness, etc., which can solve the problems of bottle deformation, high labor intensity, and labor-intensive operation. High strength and other problems, to achieve the effect of improving measurement accuracy, high degree of automation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

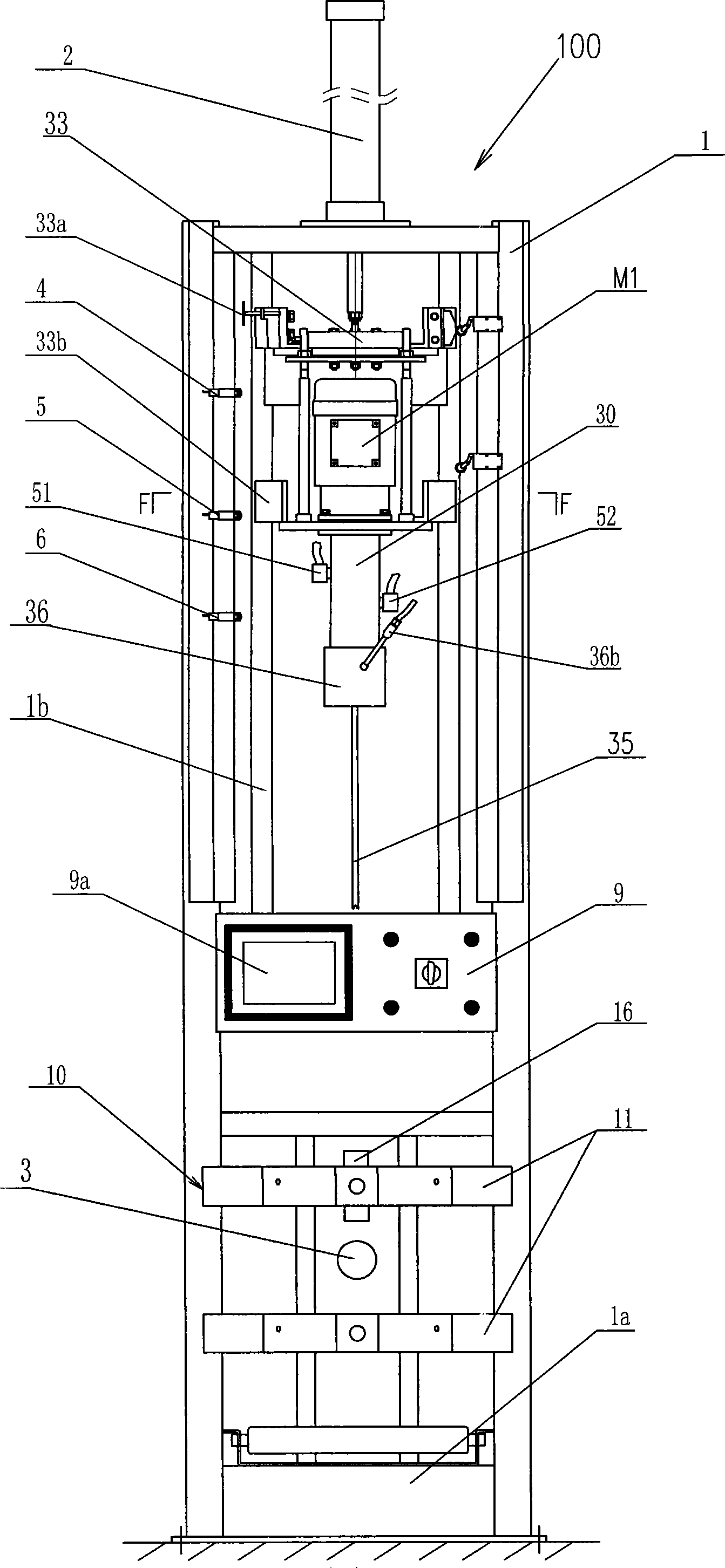

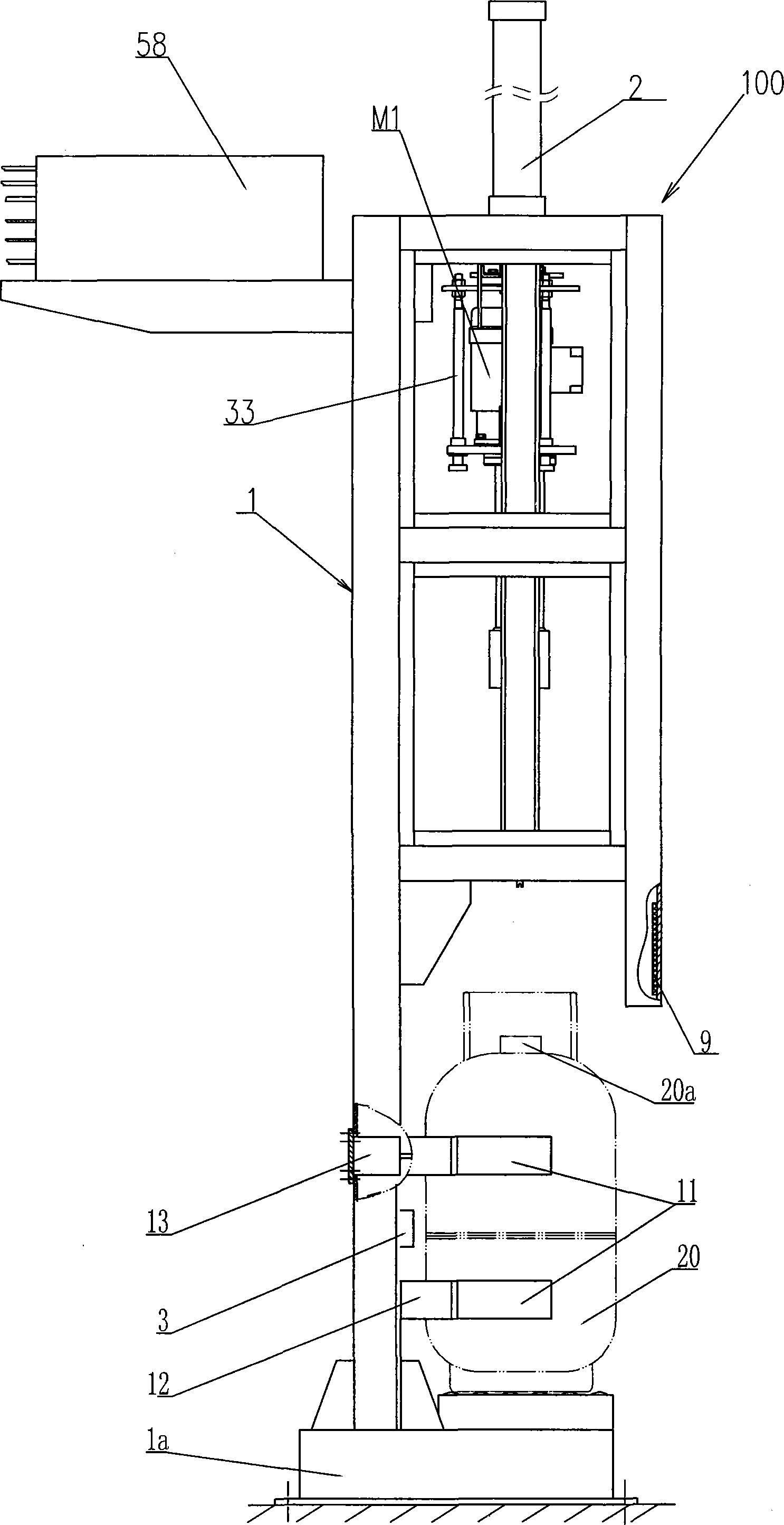

[0037]As shown in the figure, the present invention provides a gas cylinder hydrostatic test automatic test machine, the gas cylinder hydrostatic test automatic test machine 100 includes: a frame 1, a gas cylinder 20 is supported on a base 1a at the bottom of the frame 1, and The frame 1 on one side of the base 1a is equipped with an automatic bottle clamping device 10 and a first proximity switch 3 for sensing that the gas cylinder 20 is put in place. When the gas cylinder 20 is placed on the base 1a, it contacts the first proximity switch 3, the first proximity switch 3 is connected to the PLC program control circuit, and the control circuit starts the automatic bottle clamping device 10 to clamp the gas cylinder 20 for subsequent procedures.

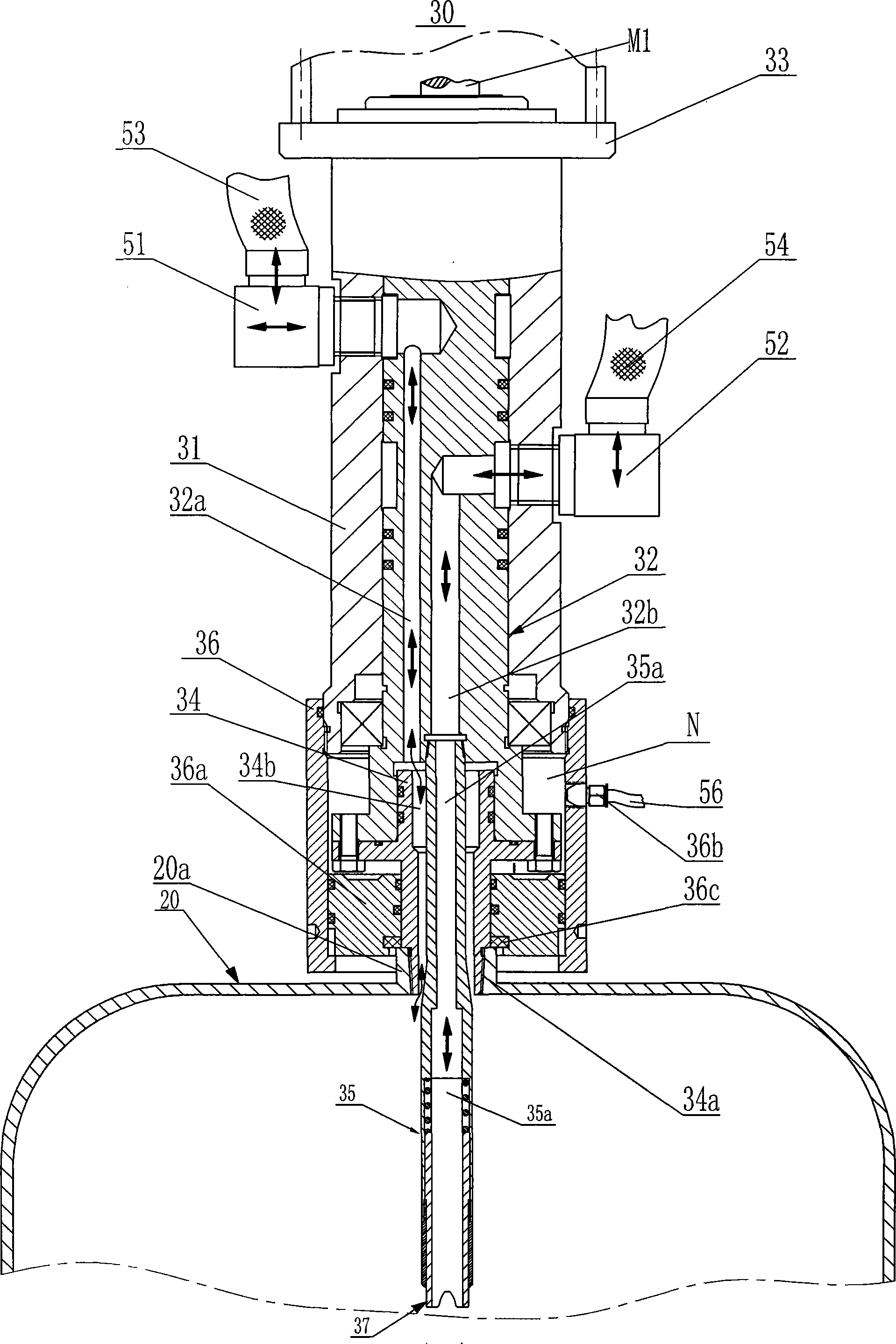

[0038] On the frame 1 on the valve seat 20a top of the gas cylinder 20, the sealing rod 30 connecting the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com