Colorful transferred lined paper

A lining paper, color technology, applied in the directions of wrapping paper, wrapping paper, flexible covering, etc., can solve the problems of too luxurious packaging, no high added value, fast smoke emission, etc., and achieve colorful, novel and economical appearance. The effect of energy and materials, process maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

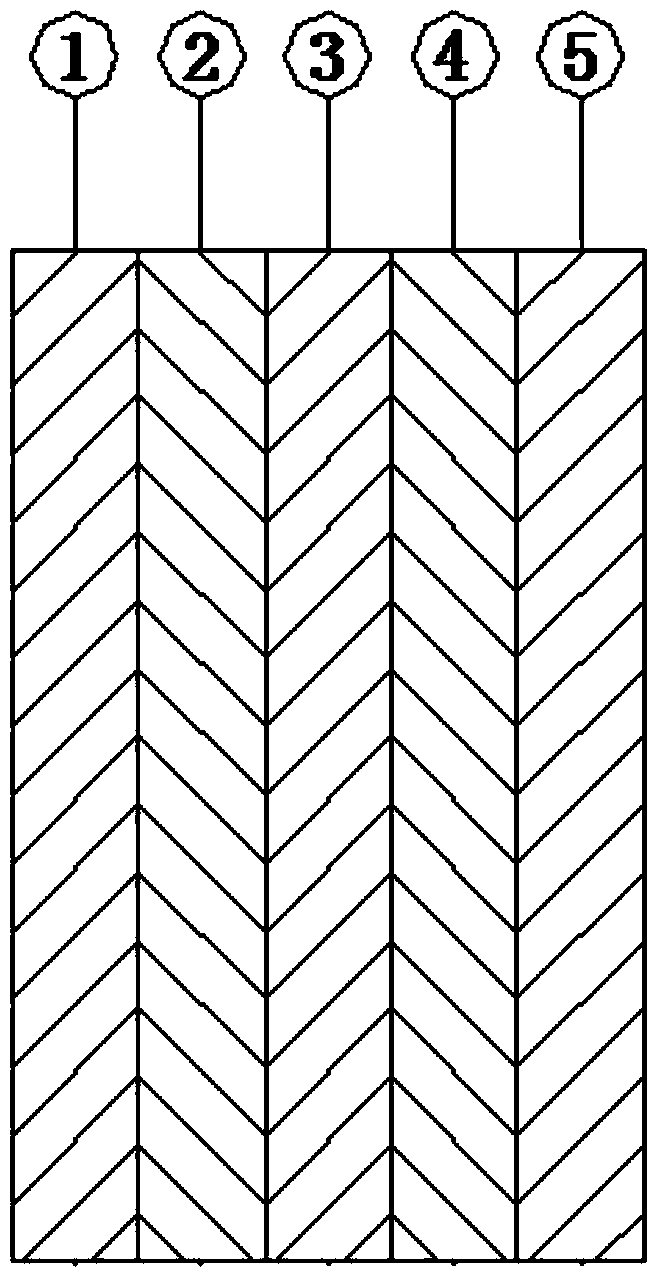

[0014] Such as figure 1 As shown, a color transfer inner lining paper includes an inner lining paper 1, a transfer adhesive layer 2, a non-ferrous metal layer 3, a release layer 4 and a PET film 5 from the inside to the outside.

[0015] Manufacturing principle:

[0016] Step 1: Coat the release layer on the surface of the PET film.

[0017] Step 2: Use advanced vacuum plating technology to coat the surface of the release layer with non-ferrous metals (melting point below 1500°C), so that the plated PET film is colored.

[0018] The third step: use the transfer glue to wet-laminate th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com