Preparation method for oxygen evolution electrode based on graphene oxide reduction

A technology of graphene oxide and oxygen evolution electrode, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems that hinder the commercial development of metal-air batteries, high oxygen evolution overpotential, and expensive electrodes, etc., and achieve excellent The effect of oxygen evolution catalytic performance, simple preparation method and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the oxygen evolution electrode based on reduced graphene oxide of the present embodiment comprises the following steps:

[0028] 1) Use concentrated sulfuric acid, sodium nitrate and potassium permanganate to oxidize graphite powder to prepare graphite oxide;

[0029] 2) The graphite oxide prepared in step 1) was ultrasonically treated at 10°C for 10 hours to prepare graphene oxide;

[0030] 3) Dilute the graphene oxide prepared in step 2) with water to a concentration of 0.5 mg / ml;

[0031] 4) The diluted graphene oxide solution obtained in step 3) was subjected to a hydrothermal reduction reaction at 180° C. for 12 hours, and the obtained product was an oxygen evolution electrode based on reduced graphene oxide.

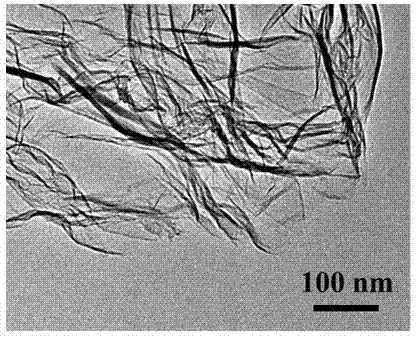

[0032] figure 1 The transmission electron microscope image of the reduced graphene oxide electrode prepared for Example 1; the flaky reduced graphene oxide structure can be clearly seen from the figure.

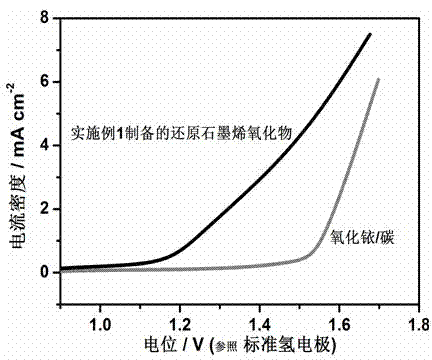

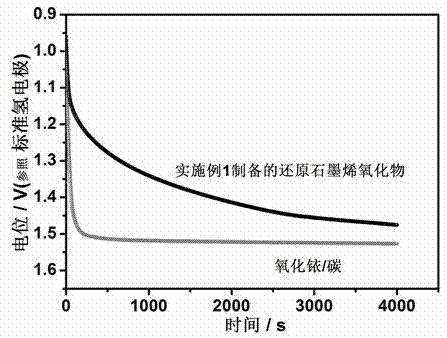

[0033] figure 2 The c...

Embodiment 2

[0037] The preparation method of the oxygen evolution electrode based on reduced graphene oxide of the present embodiment comprises the following steps:

[0038] 1) Use concentrated sulfuric acid, sodium nitrate and potassium permanganate to oxidize graphite powder to prepare graphite oxide;

[0039] 2) The graphite oxide prepared in step 1) was ultrasonically treated at 15°C for 12 hours to prepare graphene oxide;

[0040] 3) Dilute the graphene oxide prepared in step 2) with water to a concentration of 1.0 mg / ml;

[0041] 4) The diluted graphene oxide solution obtained in step 3) was subjected to a hydrothermal reduction reaction at 200° C. for 10 h, and the obtained product was an oxygen evolution electrode based on reduced graphene oxide.

[0042] Figure 4 The transmission electron microscope image of the reduced graphene oxide electrode prepared for Example 2; the flaky reduced graphene oxide structure can be clearly seen from the figure.

[0043] Figure 5 The compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com