Highly-efficient corrosion inhibitor for coal-fired boiler

A technology of coal-fired boilers and corrosion inhibitors, applied in the field of energy chemistry, can solve the problems of reduced service life of heating surfaces, explosion and leakage of boiler tubes, corrosion, etc., and achieve the effect of prolonging service life and reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of high-efficiency coal-fired boiler corrosion inhibitor, its composition and weight percentage are as follows:

[0018]

[0019] Wherein, each component weight percentage that forms emulsifying agent is:

[0020] Span 80 20%-60%

[0021] Tween 80 20%-60%

[0022] Carboxylated starch 20%-60%

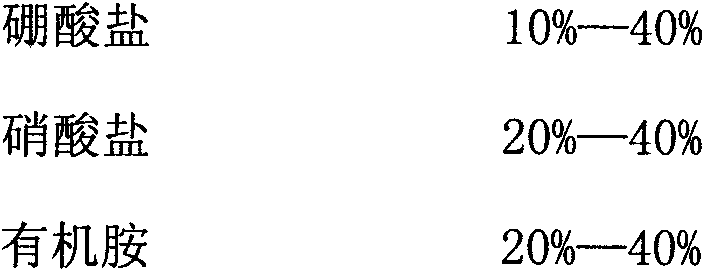

[0023] Wherein, each component and weight percent of composition chemical agent are:

[0024]

[0025] A kind of efficient coal-fired boiler corrosion inhibitor of the present invention, its preparation method is:

[0026] 1. First prepare the emulsifier: add Span 80 to a stirred tank, then add Tween 80 and carboxylated starch respectively, stir well, and prepare 100 grams of emulsifier for use as a spare.

[0027] 2. Preparation of chemical medicament: Add powdered chemical medicaments such as sodium silicate, potassium nitrate, sodium borate, triethanolamine, etc. in another stirred tank, stir evenly, and prepare 100 grams of chemical medicament for subsequent u...

Embodiment 2

[0030] A kind of high-efficiency coal-fired boiler corrosion inhibitor, its composition and weight percentage are as follows:

[0031]

[0032] Wherein, above 2 gram emulsifiers are taken out from the standby emulsifier of embodiment one, and the chemical agent of 15 grams is also taken out from the standby chemical agent of embodiment one, and its each component and weight percent are the same as embodiment one The spare emulsifier and spare chemical agent in it are exactly the same.

[0033] A high-efficiency coal-fired boiler corrosion inhibitor, the preparation method of which is consistent with that described in Example 1.

Embodiment 3

[0035] A kind of high-efficiency coal-fired boiler corrosion inhibitor, its composition and weight percentage are as follows:

[0036]

[0037] Wherein, above 1 gram of emulsifier is taken out from the standby emulsifier of embodiment one, and the chemical agent of 12 grams is also taken out from the standby chemical agent of embodiment one, and its each component and percentage by weight are the same as those in embodiment one The spare emulsifiers and spare chemicals are exactly the same.

[0038] A high-efficiency coal-fired boiler corrosion inhibitor, the preparation method of which is consistent with that described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com