Method for desulfurating and regenerating waste rubber by using microbes

A technology for regenerating waste rubber and microbial bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of high energy consumption, waste gas and waste water, and secondary pollution in the regeneration process, and achieve low equipment requirements , the process is simple and controllable, and the effect of mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Strains: Gordonia friendly, purchased from China Industrial Microorganism Culture Collection and Management Center.

[0024] Rubber: self-made isoprene rubber vulcanized rubber filled with 50 parts by weight of carbon black, self-crushed into isoprene rubber powder with a diameter of 50-200 microns.

[0025] Medium: Glucose 2g, NH 4 Cl2g, KH 2 PO 4 2.44g, Na 2 HPO 4 5.57g, MgCl 2 0.2g, CaCl 2 0.04g, FeCl 3 ·7H 2 O0.04g, MnCl 2 4H 2 O0.008g, ZnCl 2 0.001g, CoCl 2 ·6H 2 O0.004g, AlCl 3 ·6H 2 O0.001g, CuCl 2 2H 2 O0.001g, H 3 BO 3 0.001g, NaMoO 4 2H 2 O0.001g, deionized water 1000mL.

[0026] Co-cultivation-regeneration process: use 75% ethanol to soak the isoprene rubber powder for 24 hours for detoxification; add 50mL medium to a 250mL shake flask with an initial pH of 6, and sterilize at 115°C for 20 minutes; After the temperature of the culture medium dropped to 25°C, 10% (v / v) of Gordonia friendly strains were added and cultivated for 48 hours; d...

Embodiment 2

[0029] Strains: Gordonia friendly, purchased from China Industrial Microorganism Culture Collection and Management Center.

[0030] Rubber: self-made natural rubber vulcanizate, self-crushed into natural rubber powder with a diameter of 50-200 microns.

[0031] Medium: Glucose 4g, NH 4 Cl2g, KH 2 PO 4 2.44g, Na 2 HPO 4 5.57g, MgCl 2 0.2g, CaCl 2 0.04g, FeCl 3 ·7H 2 O0.04g, MnCl 2 4H 2 O0.008g, ZnCl 2 0.001g, CoCl 2 ·6H 2 O0.004g, AlCl 3 ·6H 2 O0.001g, CuCl 2 2H 2 O0.001g, H 3 BO 3 0.001g, NaMoO 4 2H 2 O0.001g, deionized water 1000mL.

[0032]Co-cultivation-regeneration process: use ethanol with a concentration of 75% by volume to soak natural rubber powder for 24 hours for detoxification; add 50mL medium to a 250mL shake flask with an initial pH of 7.0, and sterilize at 115°C for 20 minutes; After the base temperature dropped to 30°C, 10% (v / v) of Gordonia friendly strains were added and cultivated for 48 hours; detoxified natural rubber powder was added,...

Embodiment 3

[0035] Strains: Gordonia friendly, purchased from China Industrial Microorganism Culture Collection and Management Center.

[0036] Rubber: self-made styrene-butadiene rubber vulcanized rubber filled with 30 parts by weight of carbon black, self-crushed into styrene-butadiene rubber powder with a diameter of 50-200 microns.

[0037] Medium: Glucose 4g, NH 4 Cl2g, KH 2 PO 4 2.44g, Na 2 HPO 4 5.57g, MgCl 2 0.2g, CaCl 2 0.04g, FeCl 3 ·7H 2 O0.04g, MnCl 2 4H 2 O0.008g, ZnCl 2 0.001g, CoCl 2 ·6H 2 O0.004g, AlCl 3 ·6H 2 O0.001g, CuCl 2 2H 2 O0.001g, H 3 BO 3 0.001g, NaMoO 4 2H 2 O0.001g, deionized water 1000mL.

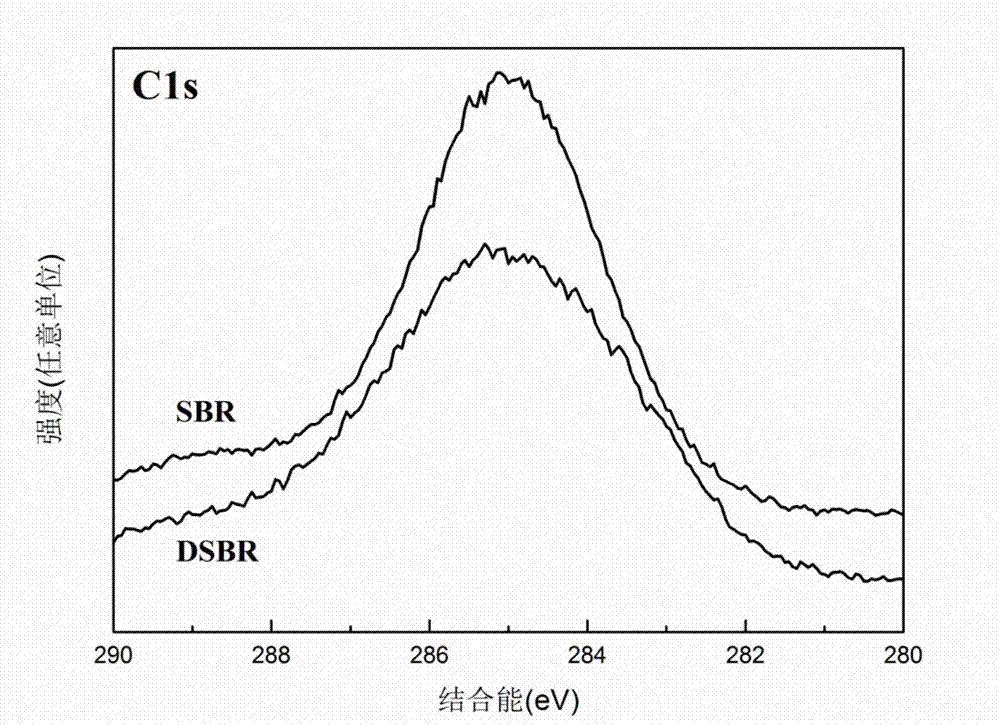

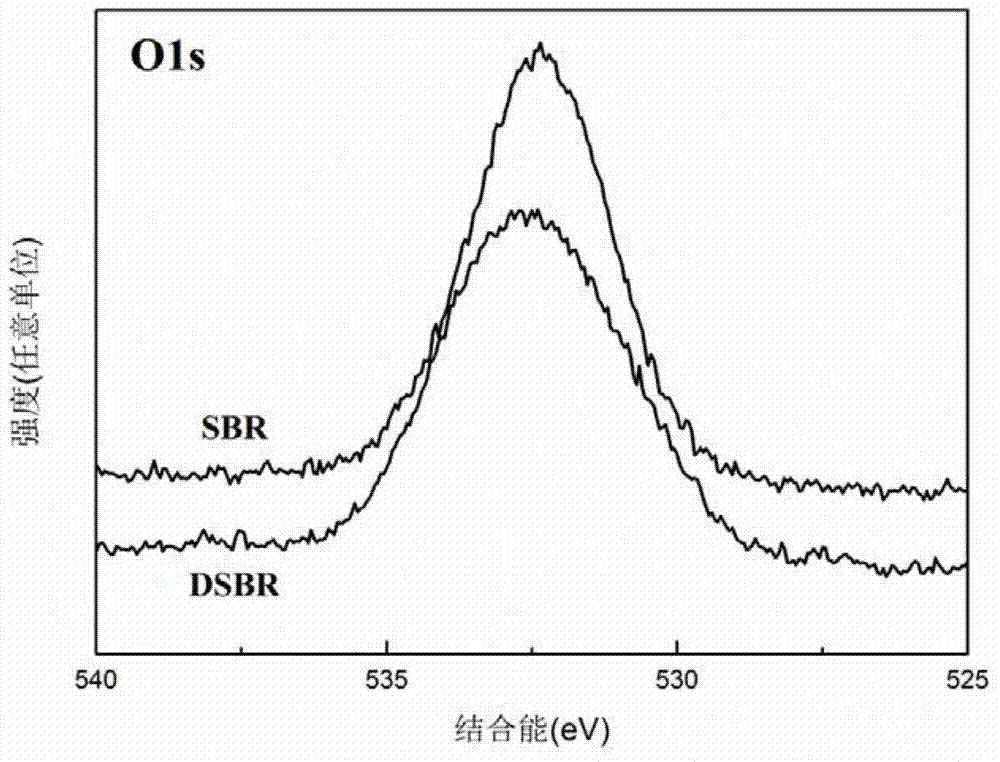

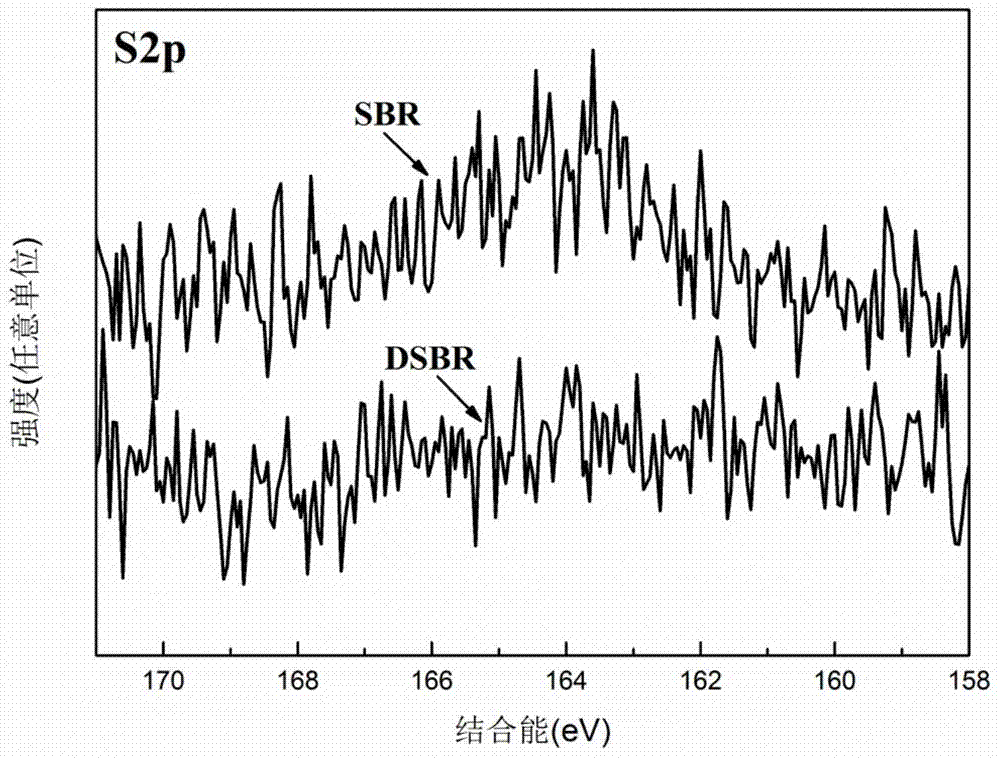

[0038] Co-cultivation-regeneration process: Soak styrene-butadiene rubber powder in 75% ethanol for 24 hours for detoxification; add 50 mL of culture medium to a 250 mL shake flask with an initial pH of 7.0, and sterilize at 115°C for 20 minutes; After the temperature of the culture medium dropped to 30°C, 10% (v / v) of Gordonia friendly strains were ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com