PCB developing tank cleaning solution and method for cleaning developing tank by using same

A tank cleaning and developer technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of poor development, affecting the development spray pressure, easy to adhere to the cylinder, etc., to achieve ideal cleaning effect and short cleaning time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

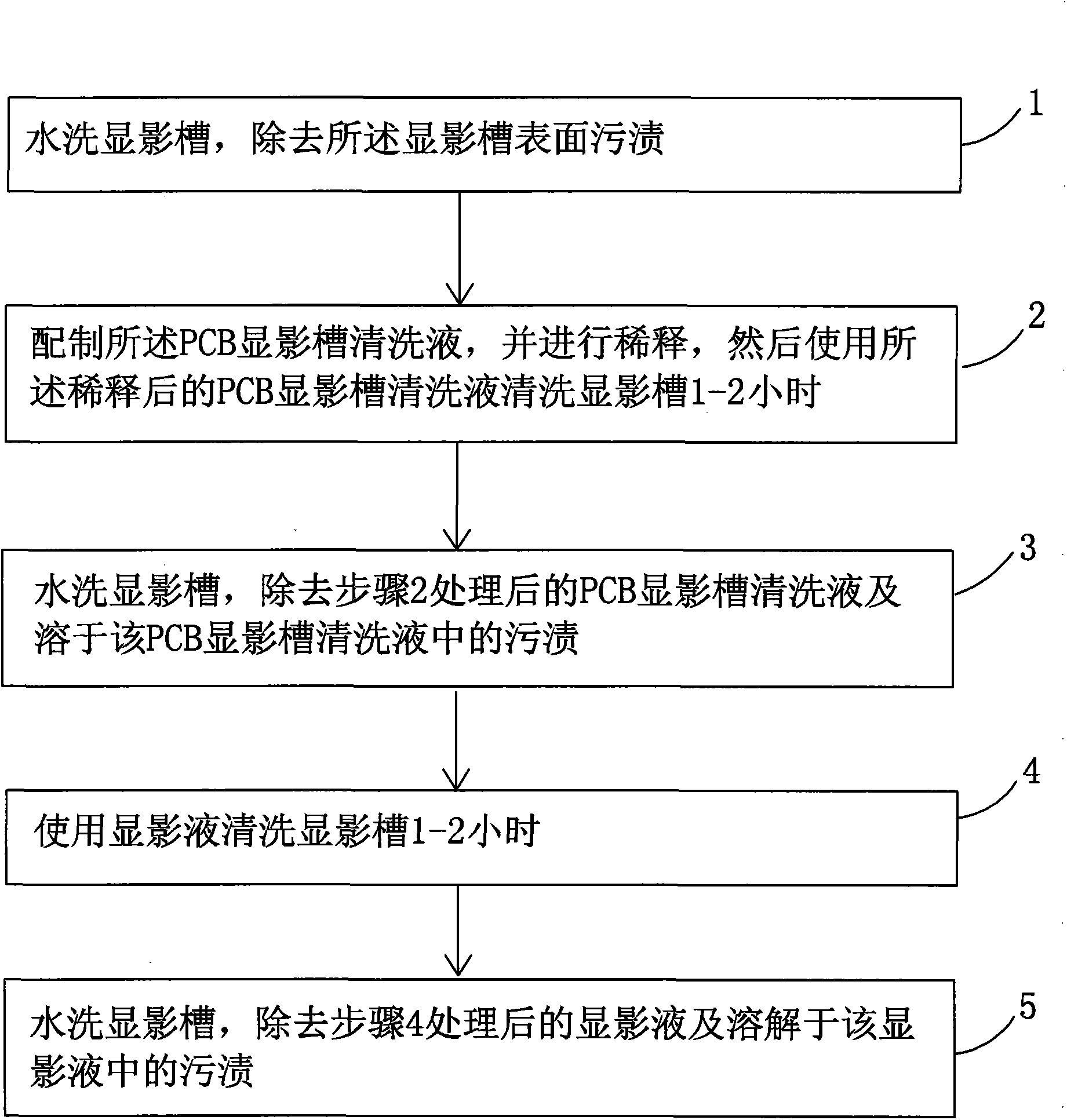

Method used

Image

Examples

Embodiment Construction

[0053] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0054] The present invention provides a cleaning solution for PCB developing tank, which comprises components and mass percentages as follows:

[0055] Ethylene glycol butyl ether 10-20%,

[0056] Emulsifier 15-30%,

[0057] Acid 20-40%,

[0058] The balance is water.

[0059] Among them, ethylene glycol butyl ether is a colorless and flammable liquid. Because of its chemical structure, it has two groups with strong solubility functions - ether bond and hydroxyl group. The former is lipophilic and can dissolve hydrophobic compounds, while the latter It is hydrophilic and can dissolve hydrophilic compounds, so it has a strong dissolving ability and is known as a "universal solvent". As the bulking agent of the PCB developing tank cleaning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com