Foam concrete solid powdery foaming agent and use method thereof

A foam concrete and foaming agent technology, applied in the field of foaming agent, can solve the problems of defoaming and poor adaptability, and achieve the effect of uniform color, good foam stabilizing ability and fine foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of foamed concrete solid powder blowing agent, it is made up of following raw material of percentage by weight:

[0039] Raw material parts by weight

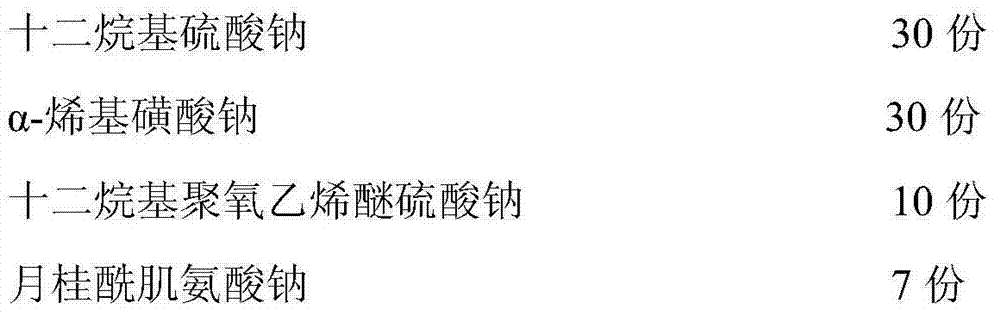

[0040] (1) Anionic surfactants:

[0041]

[0042] (2) Non-ionic surfactants

[0043] Fatty acid alkanolamides 4 parts

[0044] (3) Chelating agent

[0045] 3 parts triethanolamine

[0046] (4) Foam stabilizer

[0047] 1 part polypropylene crosslinking resin

[0048] 1 part polyacrylamide

[0049] 1 part hydroxyethyl cellulose

[0050] The using method of above-mentioned a kind of foam concrete solid powder foaming agent, comprises the following steps:

[0051] (1) Stir and dissolve the solid powder foaming agent in hot water at 80°C, and control the mass ratio of the two within the range of 1:8 to form a common liquid foaming agent.

[0052] (2) Mix the formed ordinary liquid foaming liquid with ordinary normal temperature tap water, and control the mass ratio of the two within the range of 1:60;

[005...

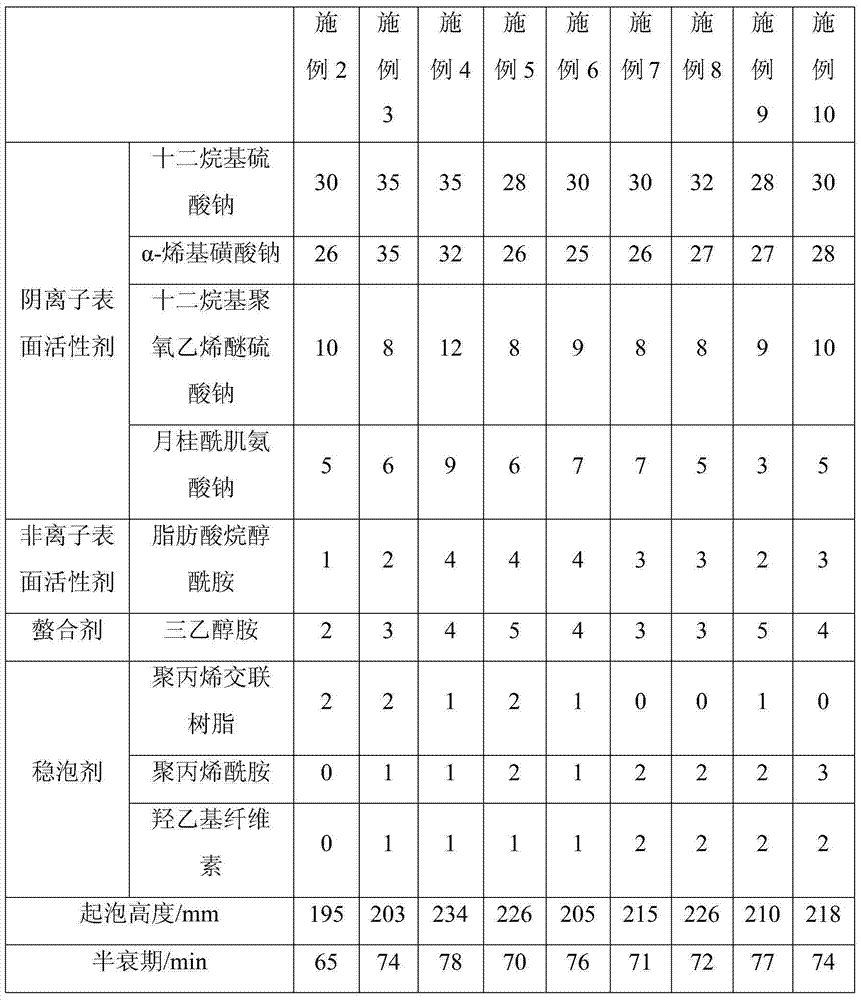

Embodiment 2

[0055] The formula is shown in Table 1, and the method of use includes the following steps:

[0056] (1) Stir and dissolve the solid powder foaming agent in hot water at 60°C, and control the mass ratio of the two within the range of 1:6 to form a common liquid foaming agent.

[0057] (2) Mix the formed ordinary liquid foaming liquid with ordinary warm tap water, and control the mass ratio of the two within the range of 1:50;

[0058] (3) Foaming through a foaming machine, mixed with cement slurry at a volume ratio of 5:1 to form a 400kg / m 3 Density grade foamed concrete.

Embodiment 3

[0060] The formula is shown in Table 1, and the usage method includes the following steps:

[0061] (1) Stir and dissolve the solid powder foaming agent in hot water at 90°C, and control the mass ratio of the two within the range of 1:6 to form a common liquid foaming agent.

[0062] (2) Mix the formed ordinary liquid foaming liquid with ordinary warm tap water, and control the mass ratio of the two within the range of 1:50;

[0063] (3) Foam through a special foaming machine, and mix with cement slurry at a volume ratio of 7:1 to form a 300kg / m 3 Density grade foamed concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com