Sheet clamp

A gripper and sheet technology, which is applied in the field of high-definition detail image acquisition and dynamic image continuous acquisition devices, can solve the problems of image analysis influence and displacement experiment data reliability, and achieve the effect of accurate image analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

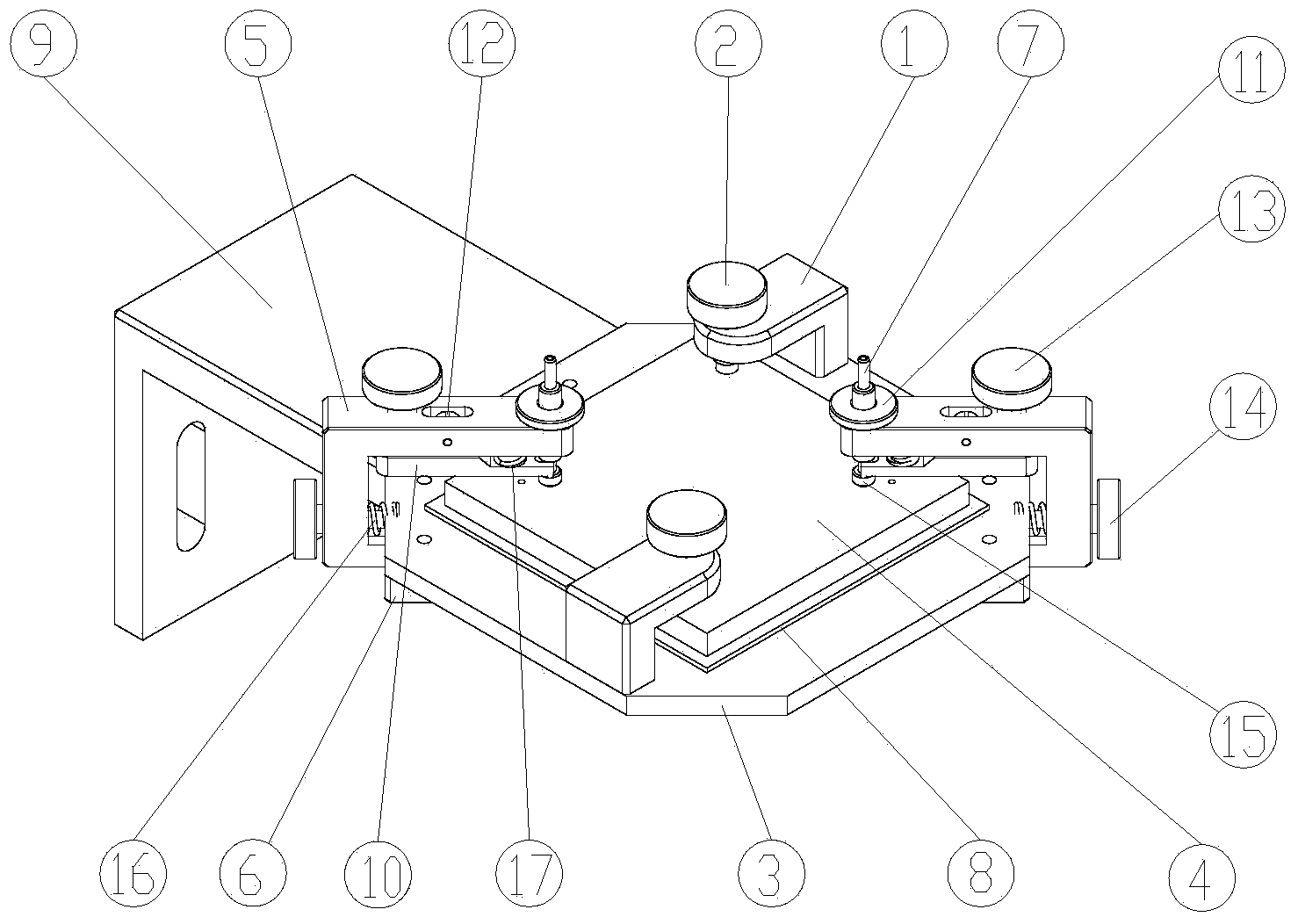

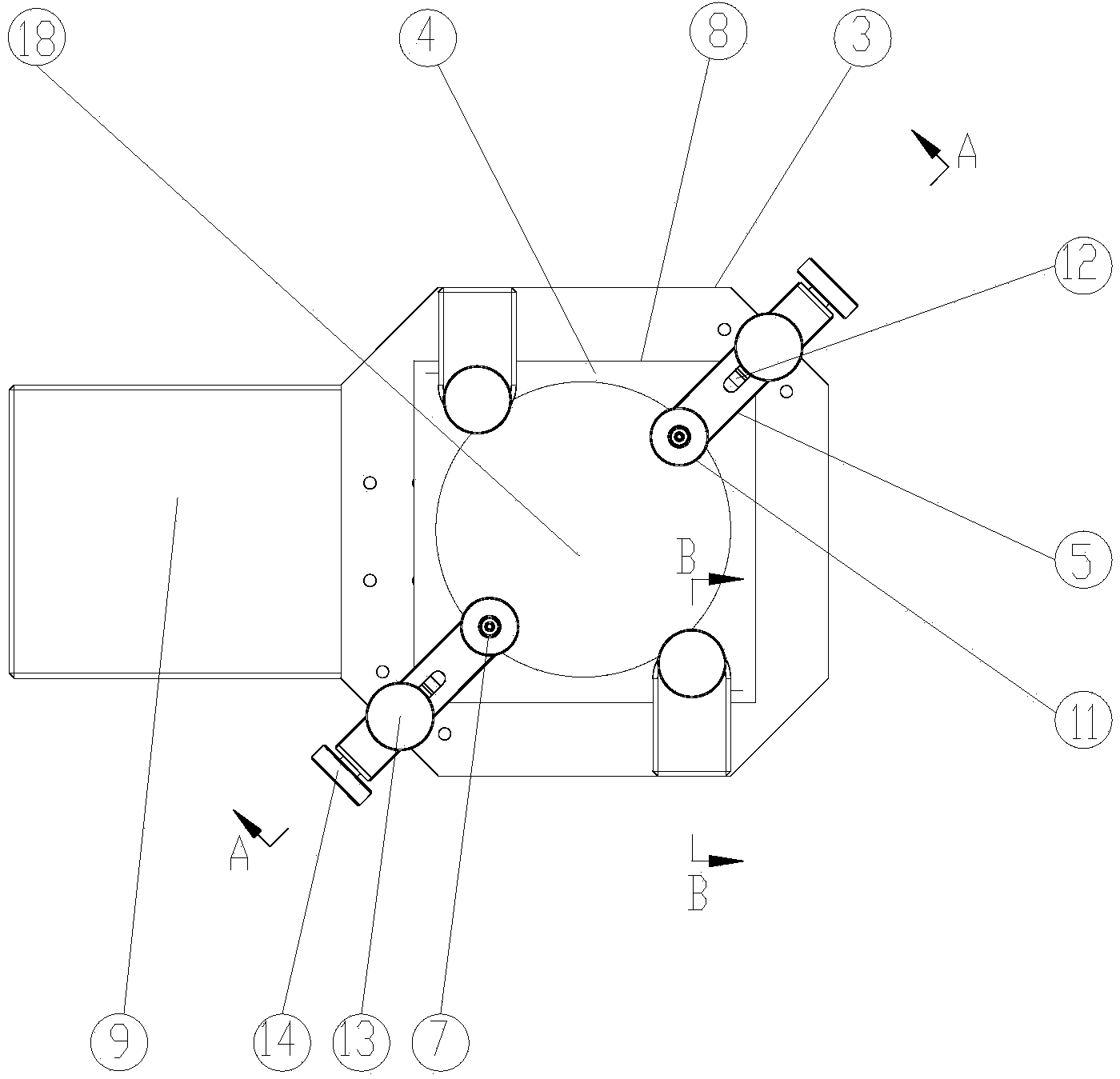

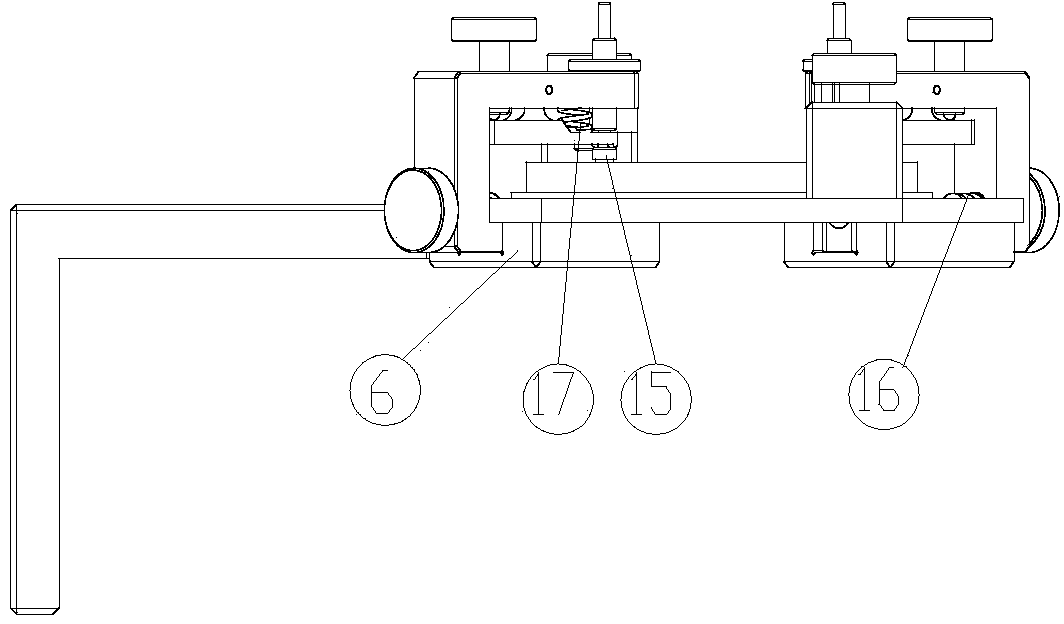

[0031] Embodiment: A sheet holder, including a holder substrate 3, a holder support frame 9 and two holder frames 5, the holder substrate 3 is a cube shape, and the holder substrate 3 is installed on the holder On the support frame 9, two clamping frames 5 are installed on two opposite corners of the clamper base plate 3, and detachable liquid connectors 7 are arranged on the two clamping frames 5; the clamping frame 5 includes an upper cross bar , the lower cross bar and the longitudinal bar, the two ends of the longitudinal bar are vertically connected with the upper cross bar and the lower cross bar respectively, the upper cross bar and the lower cross bar are arranged in parallel, and the lower part of the upper cross bar is provided with a gripper lever 10 for clamping The device lever 10 is movably connected with the upper cross bar with the cylindrical pin 12 arranged in the clamping frame 5 as a fulcrum, and the upper cross bar is provided with a compression screw 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com