Electrostatic protective component and method for manufacturing same

A technology of electrostatic protection and manufacturing method, which is applied in the direction of electrical components, circuits, spark gaps, etc., can solve the problems of increased manufacturing cost of electrostatic protection components, expensive manufacturing equipment, personal injury, etc., to prevent deterioration of the back electrode, cheap manufacturing equipment, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

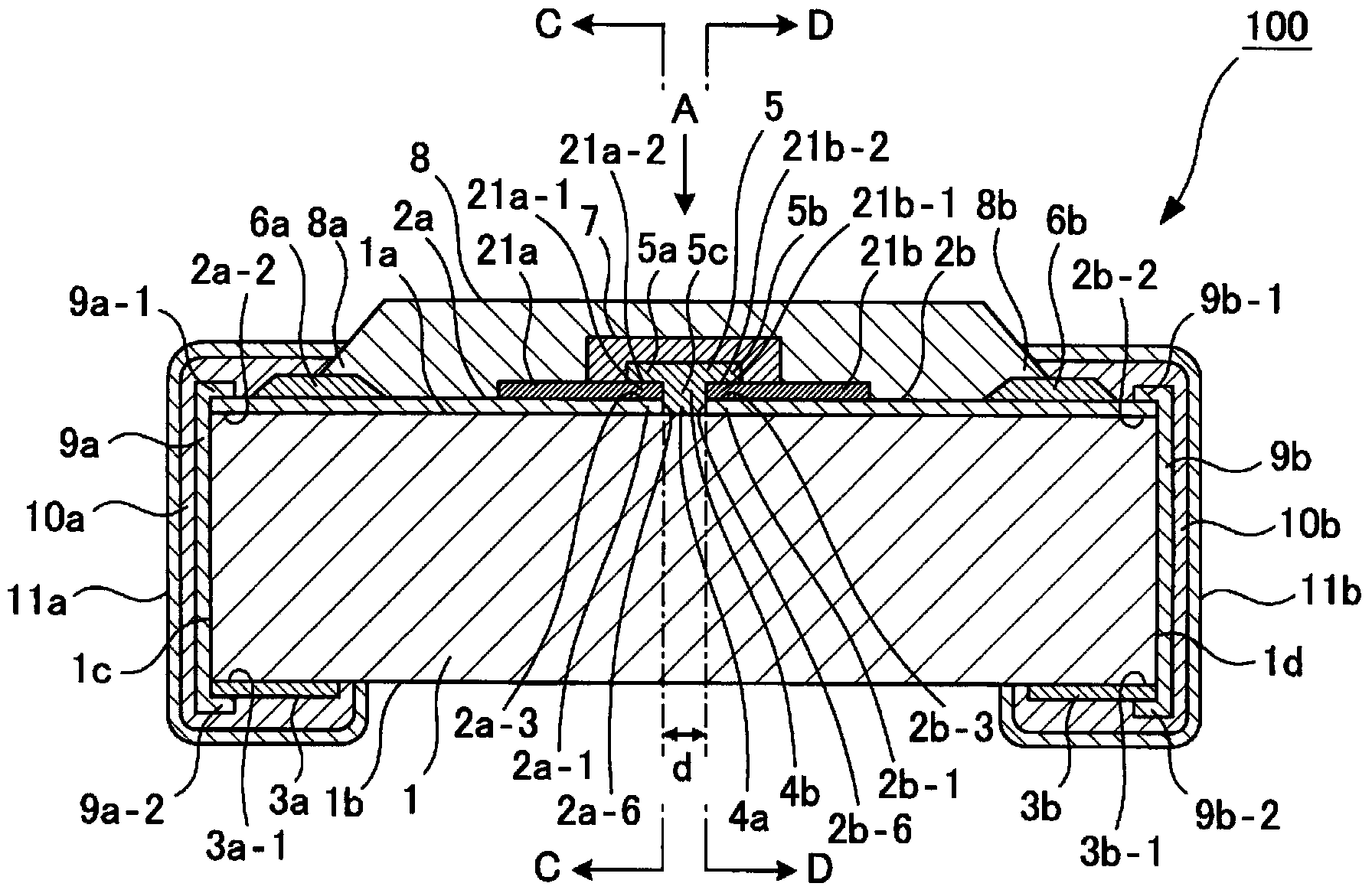

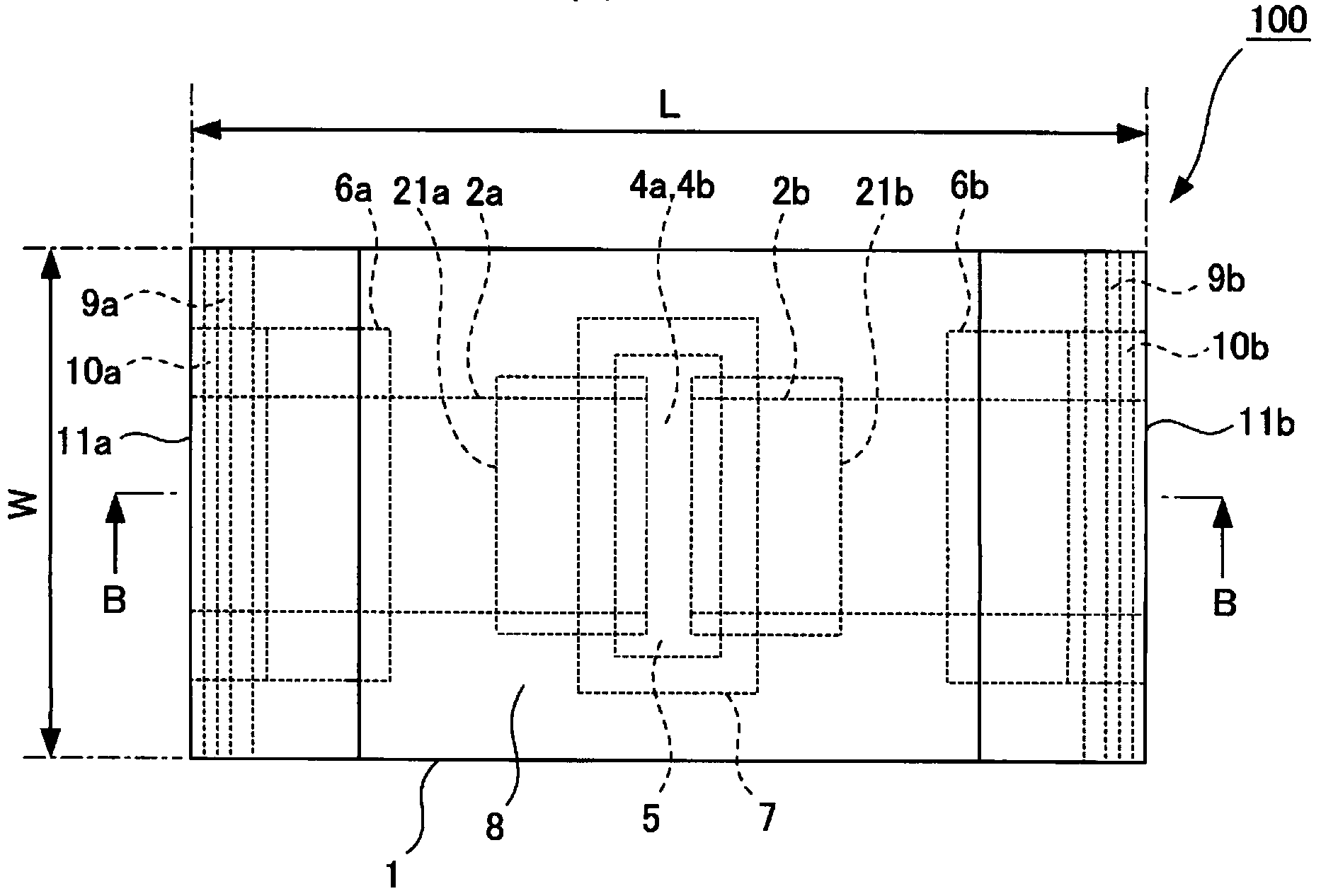

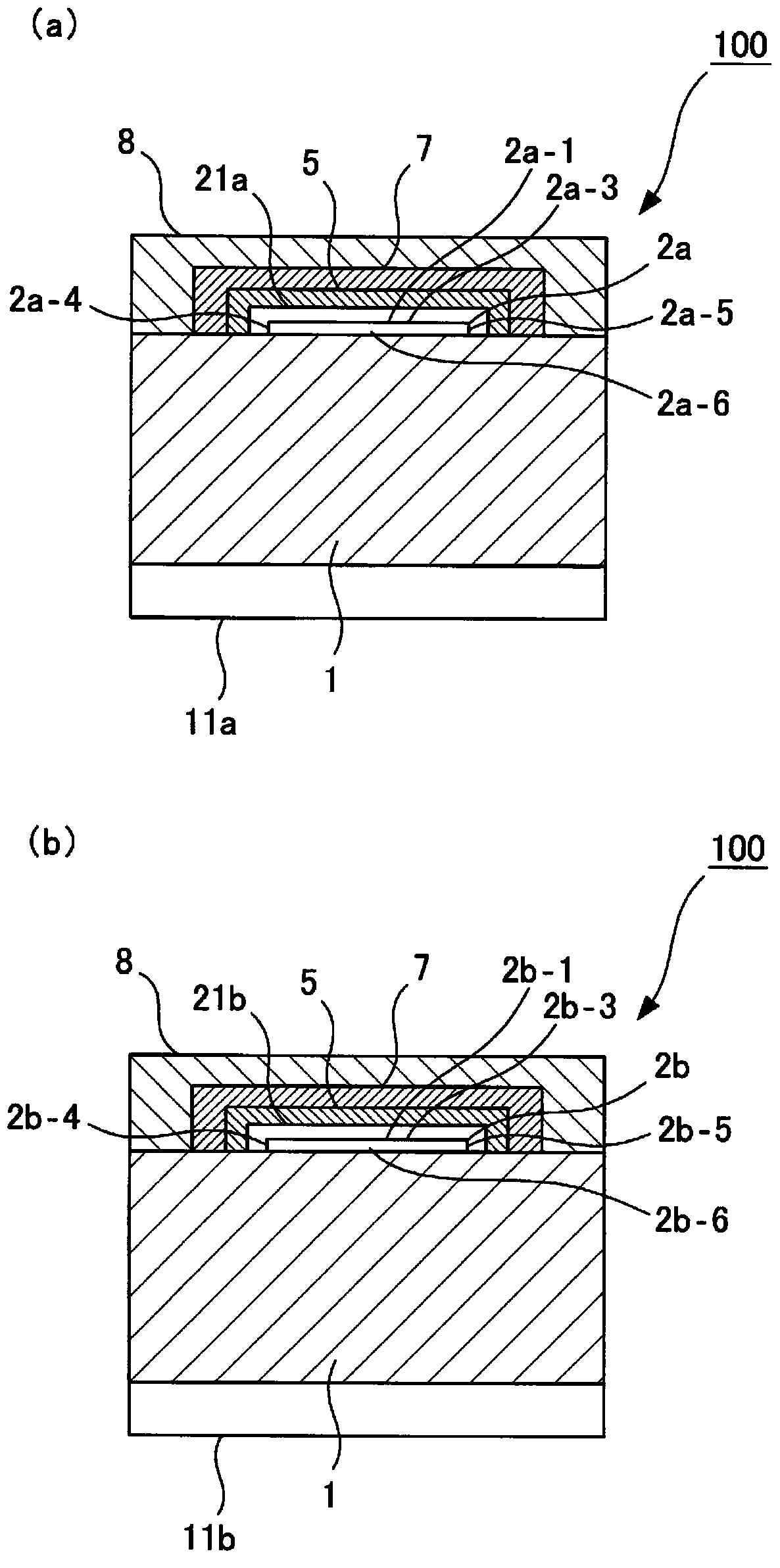

[0067] Hereinafter, embodiments of the present invention will be specifically described based on the drawings.

[0068] First, according to Figure 1 to Figure 4 The structure and the like of the electrostatic protection device according to the embodiment of the present invention will be described.

[0069] figure 1 The electrostatic protection element 100 shown is an element surface-mounted on a printed circuit board such as an electronic device for a vehicle, and is designed to protect an electronic circuit (electronic component) mounted on the printed circuit board from overvoltage caused by external noise or the like. , in the electronic device, the electrostatic protection element 100 is arranged between a line to which the overvoltage may be applied and a ground.

[0070] like Figure 1 ~ Figure 3 As shown, surface electrodes 2a, 2b are formed on a surface 1a of a ceramic substrate 1, which is an insulating substrate. In addition, a copper (Cu)-nickel (Ni) film or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com