Bulk hydrophilic funtionalization of polyamide 46

A technology of polyamide and body, which is applied in the field of polyamide 46 body hydrophilic functionalization, which can solve the problems of no flexibility and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

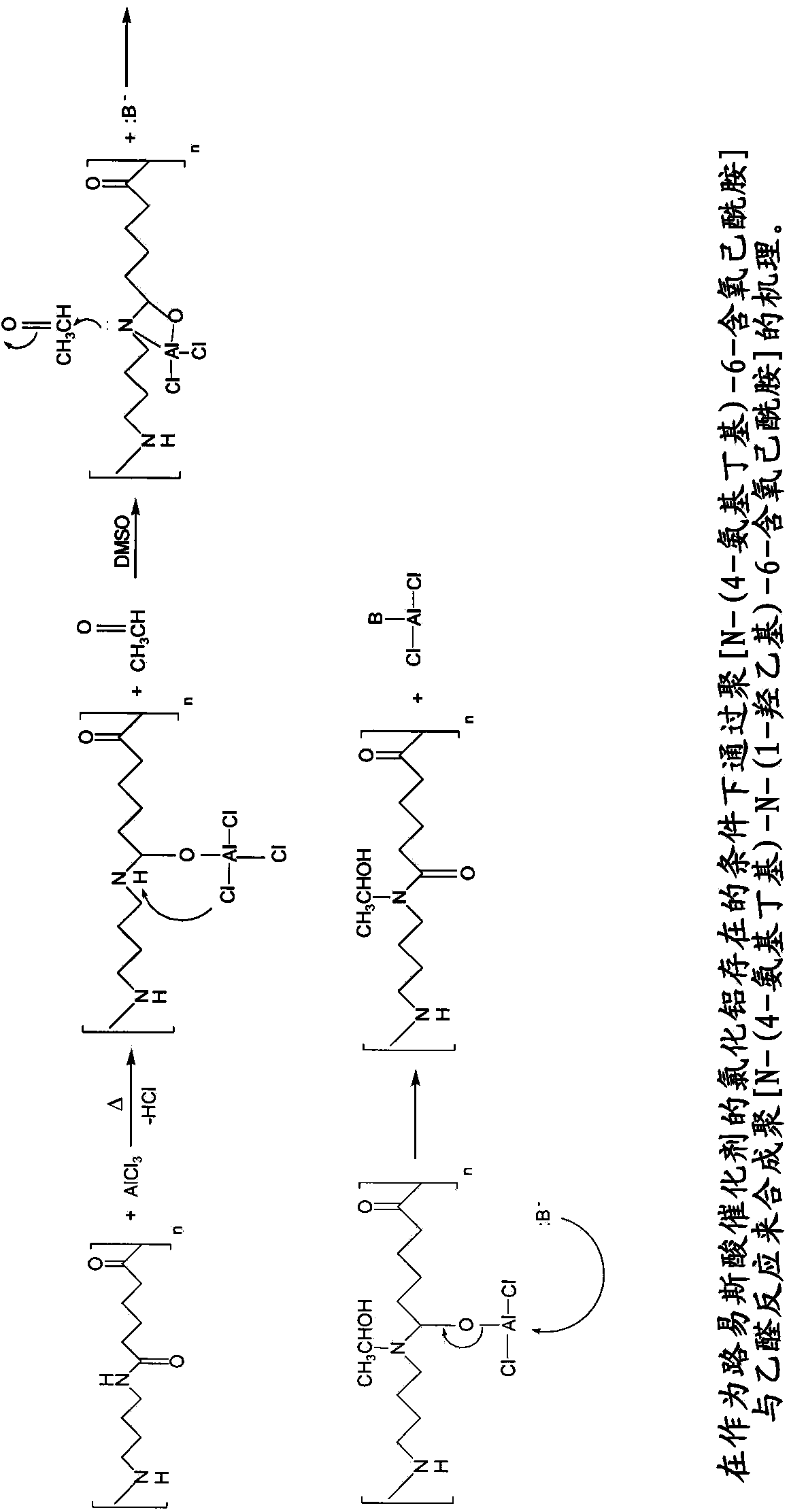

Method used

Image

Examples

Embodiment 1

[0030] Polyamide 46 (Stanyl TW300, M n ~24000 g / mol) was heated in an oven for 3 h to 50±2°C, and then dried to constant weight. Gradually, 10 g of dry polyamide were added to 80 mL of ≥98% formic acid (1.22 g / mL at 25 °C) and stirred gently for 2 h to obtain a continuous dispersion at this concentration. Then, 10 mL of 99.8% ethanol (0.791 g / mL at 25°C) and 42 mL of >99.5% dimethylsulfoxide (1.10 g / mL at 25°C) were added to the mixture. Then, the solution was poured into a 500 ml three-necked round bottom flask immersed in a water bath and connected to a thermometer. Then add 1.82 g of anhydrous AlCl 3 (Purity ≥ 99.9%). The temperature was then maintained at 75±2°C for 1 h. Dissolve AlCl completely in the polymer solution 3 Afterwards, lower the temperature to room temperature. Then, 10 mL of ≥99% acetaldehyde (0.785 g / mL at 25 °C) was slowly added, which is attributed to the exothermic reaction of the aldehyde and the aluminum complex. The flask was fitted with a cond...

Embodiment 2

[0047] 15 g of polyamide 46 (Stanyl TW300, M n~24000g / mol) in an oven at 55±2°C for 1h. Disperse the dried polyamide 46 into 100 mL, ≥98% formic acid solution (1.22 g / mL, at 25 °C) by mixing and warming at 50 ± 2 °C. After this process, 20 mL of formaldehyde solution at a concentration of ~37% in water was added to the mixture. Raise the temperature and keep it at 50±2°C for 1h. After the reaction, the temperature was adjusted to room temperature to obtain a viscous solution. Then, 250 mL of methanol (≥99%) was added to the cloudy solution and mixed for 5 min. The highly viscous polymer was removed by phase separation in a decanter. This stage was repeated 2 times to remove any residue of formaldehyde. The polymer paste was dried in an oven at 50 °C for 6 h.

Embodiment 3

[0049] 15 g of polyamide 46 (Stanyl TW300, M n ~24000g / mol) in an oven at 55±2°C for 1h. Disperse the dried polyamide 46 into 100 mL of ≥98% formic acid (1.22 g / mL at 25 °C) by stirring. After this process, 20 mL of ≥99.5% dimethyl sulfoxide (1.10 g / mL at 25 °C) and 42 mL of ≥99.5% dimethyl sulfoxide (1.10 g / mL at 25 °C) were added to the mixture . The temperature was raised and held at 67 °C for 1 h. After the reaction, the temperature was lowered to room temperature to obtain a transparent orange-red solution. Then, 11.34 mL of >99% acetaldehyde (0.785 g / mL at 25 °C) was added to the solution. After that, the temperature was fixed at 70±2°C for 20 minutes. After lowering the temperature to 25±2°C, add 250mL of methanol (≥99%) to the pale yellow solution and mix for 5min. The suspended white precipitate of the modified polyamide was taken out by centrifugation twice at 9000×g for 10 min. This phase is repeated 2 times. The modified polymer was then removed and dried a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com