Snap-action temperature controller with high sensitivity

A jump-type thermostat and high-sensitivity technology, which is applied to thermal switch components and other directions, can solve problems such as fire accidents, poor sensitivity, and slow temperature-sensing action speed, so as to improve the heat absorption efficiency of heat radiation and improve sensitivity and safety, and the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

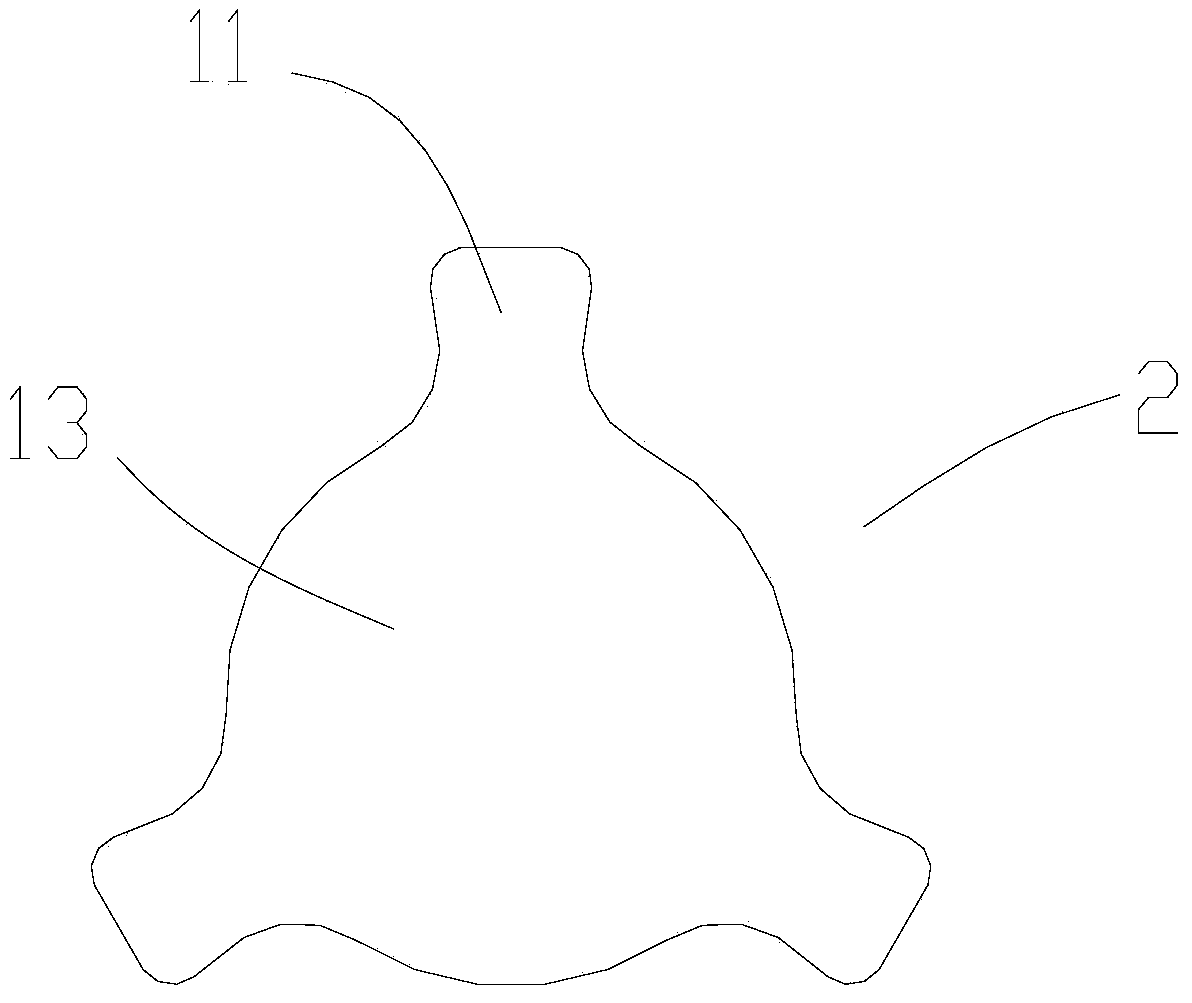

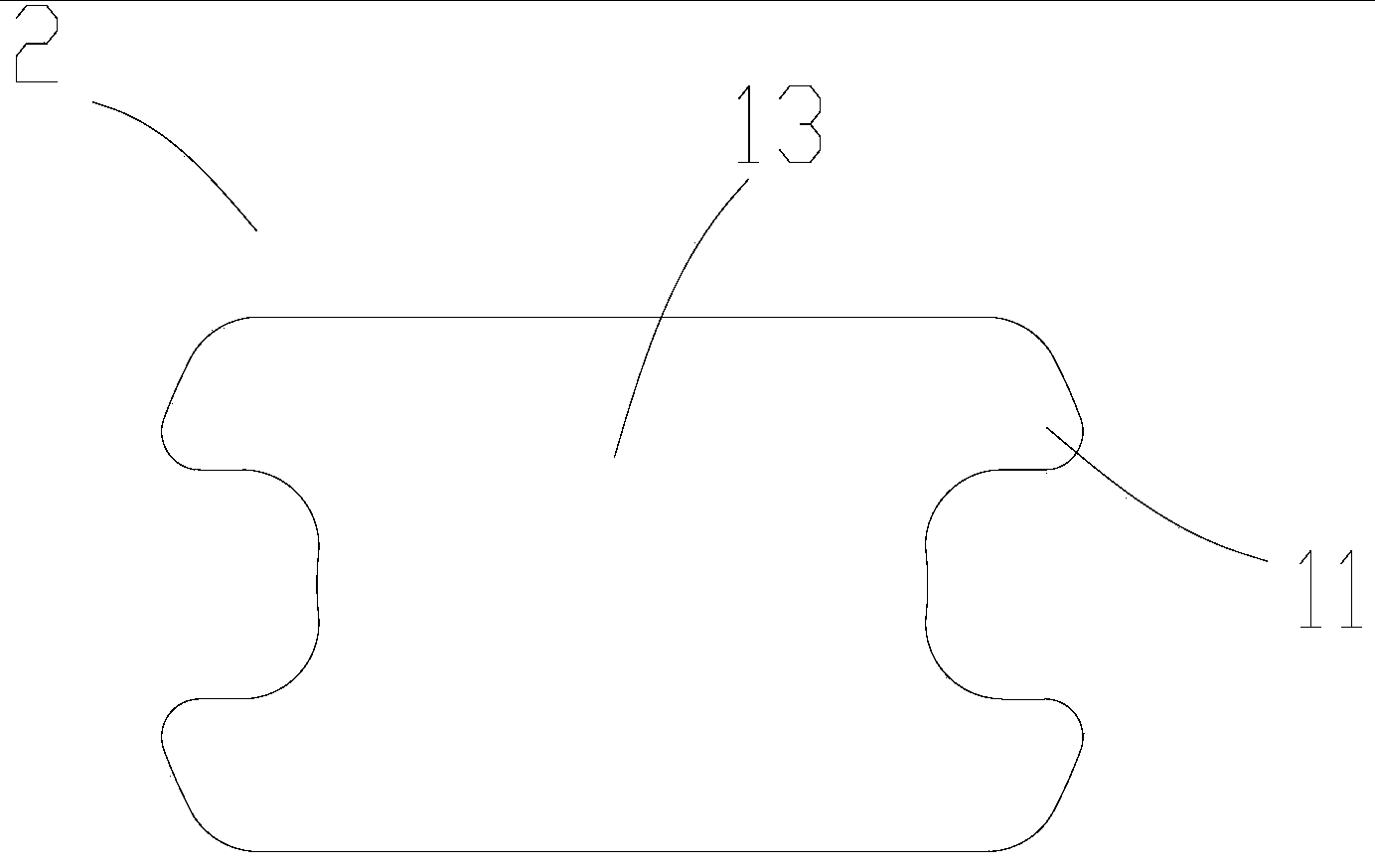

[0035] see figure 1 , figure 2 and image 3 , a high-sensitivity jump-type temperature controller, including: shell 9, rivet 5, moving reed 8, moving contact 7, fixed plate 14, fixed contact 6, ceramic rod 4, guide seat 3, double The metal temperature sensing piece 2 and the cover 1; the moving reed 8 has a fixed end and a movable end, and the fixed end of the moving reed 8 is fixed to the inner cavity of the shell 9 by a rivet 5; the moving contact 7 is fixed on the moving reed 8; the fixed contact 6 is fixed to the inner cavity of the housing 9 through the fixed plate 14 and the rivet 5, and the fixed contact 6 is arranged opposite to the movable contact 7; the center of the guide seat 3 is provided with a guide hole, and the guide seat 3 Installed on the top of the shell 9; the bimetallic temperature sensing piece 2 is located on the guide seat 3, the bimetallic temperature sensing piece 2 has a central part 13, and the periphery of the central part 13 has no less than t...

Embodiment 2

[0060] see Figure 4 , The only difference between this embodiment and Embodiment 1 is that: as an improvement, the high-sensitivity jump-type thermostat in this embodiment is additionally provided with a movable bracket 15 . The movable bracket 15 is provided with a fixing hole, and the movable bracket 15 is sleeved on the outside of the casing 9 .

[0061] The movable bracket 15 provided with the fixing hole can be used for installing and fixing the temperature controller. The movable support 15 can move up and down along the outside of the shell 9, and can freely rotate 360 degrees outside the shell 9 at the same time. Moreover, when the movable bracket 15 moves to the outside of the cover 1, the cover 1 has a clamping effect on the movable bracket 15, so that the movable bracket 15 is clamped and fixed. This greatly enhances the convenience of thermostat installation.

Embodiment 3

[0063] see Figure 5 , the only difference between this embodiment and Embodiment 1 is that: as an improvement, the cover 1 of the high-sensitivity snap-type thermostat in this embodiment is provided with an installation earring 16, and the installation earring 16 is integrally formed with the cover 1, And be provided with fixing hole on installing earring 16.

[0064] The installation earring 16 provided with the fixing hole can be used for installing and fixing the thermostat. Although the installation earrings 16 on the cover 1 are not as movable as the movable bracket 15 in the second embodiment, the installation earrings 16 and the cover 1 are integrally formed by one-time stretching of the mold, which is convenient for processing and saves processing costs ; At the same time, during the production process of the thermostat, one less part can be placed, thereby improving the assembly efficiency of the thermostat.

[0065] The working principle and function of the high-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com