A ±660kv DC Composite Insulator

A technology of composite insulators and umbrella sheds, which is applied in the direction of insulators, suspension/strain insulators, electrical components, etc., can solve the problems of threatening the operation safety of DC transmission lines, and the serious pollution speed of DC external insulation surface, so as to improve the electric field distribution, Good anti-ice and snow flash, increase the effect of creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

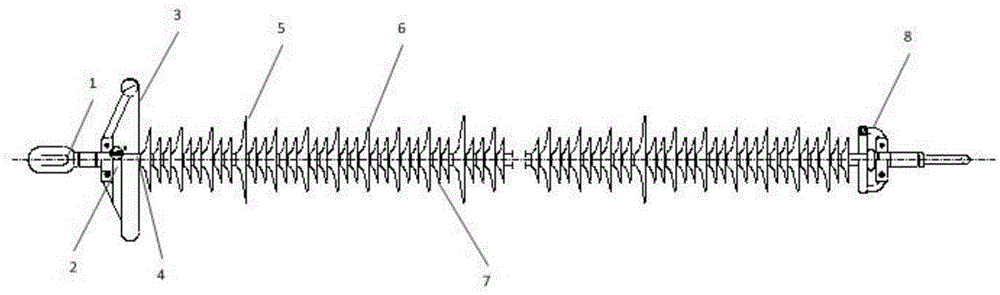

[0013] Such as figure 1 As shown, the preferred embodiment of the present invention, the ±660kV composite insulator with a nominal structural height of 9200mm is further described in conjunction with the accompanying drawings.

[0014] according to figure 1 , a ±660kV DC composite insulator, including an annular metal connector 1 at the end, a sealing ring 2 at the end of the mandrel, a voltage equalizing ring 3 at the grounding end, an epoxy resin glass fiber rod at the center and its surface covered Sheath 4, several extra large sheds 5 on the surface of the sheath, several large sheds 6 on the surface of the sheath, several small sheds 7 on the surface of the sheath, and a small pressure equalizing ring 8 at the high-voltage end; ring metal connectors at the end 1 After hot-dip galvanizing treatment; the pressure equalizing ring at the grounding en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com