Composite material connecting skirt forming method and mold and inner rubber core mold forming mold

A composite material and molding method technology, which is applied in the field of molds and their rubber inner core mold forming molds, and the molding method of composite material connecting skirts, can solve the problem that the total weight and specific impulse of the engine casing have great influence, and the surface finish of the product cannot be guaranteed. , the inability to form composite material connecting skirts, etc., to achieve good quality consistency, improve product structure efficiency, and solve the problem that the degree of squeegee is difficult to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The size and performance parameters of the composite material connecting skirt for the motor casing prepared in this embodiment are as follows in Table 1:

[0035] Table 1

[0036] serial number

[0037] The molding method of the composite material connecting skirt comprises the following steps:

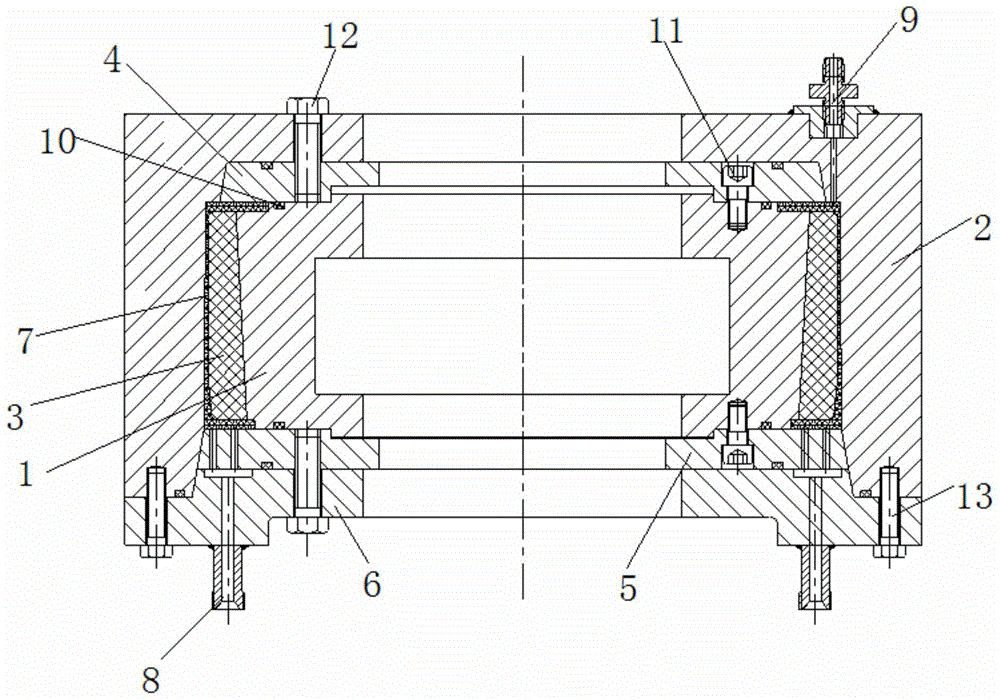

[0038] 1) Making a forming mold: making an outer mold, an inner mold, and a rubber inner core mold. The shape is matched, the shape of the inner mold is matched with the inner shape of the rubber inner mandrel; then a layer of release agent is evenly applied on the outer wall of the inner mold, and the release agent is silicone grease or PMR-70. The rubber inner core mold is set on the outer wall of the inner mold;

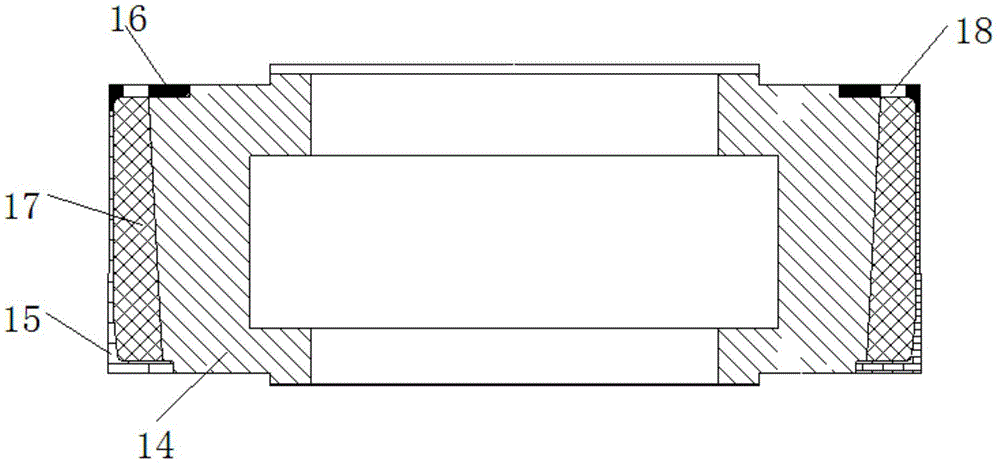

[0039] Among them, the process of forming the rubber inner mandrel by using the rubber inner mandrel molding die is as follows:

[0040] a. Preparation of rubber glue: use R10301 rubber, prepare 5kg of rubber glue according to the mass ratio of rubber...

Embodiment 2

[0053] The size and performance parameters of the composite material connecting skirt for the engine case prepared in this embodiment are as follows in Table 3:

[0054] table 3

[0055] serial number

[0056] The molding method of the composite material connecting skirt comprises the following steps:

[0057] 1) Making a forming mold: making an outer mold, an inner mold, and a rubber inner core mold. Shape matching, the shape of the inner mold matches the inner shape of the rubber inner mandrel; then apply a layer of release agent evenly on the outer wall of the inner mold, and set the rubber inner mandrel on the inner mold outer wall;

[0058] Among them, the process of forming the rubber inner mandrel by using the rubber inner mandrel molding die is as follows:

[0059] a. Preparation of rubber glue: use R10301 rubber, prepare 5kg of rubber glue according to the mass ratio of rubber emulsion: vulcanizing agent = 95%: 5%, stir evenly, put the rubber glue into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com