The method of judging the hinges with ring marks produced by parallel machine tools

A wheel pattern and machine tool technology, which is applied in metal processing machinery parts, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of shape error, affecting the accuracy of workpieces processed by parallel machine tools, and achieve the effect of improving processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

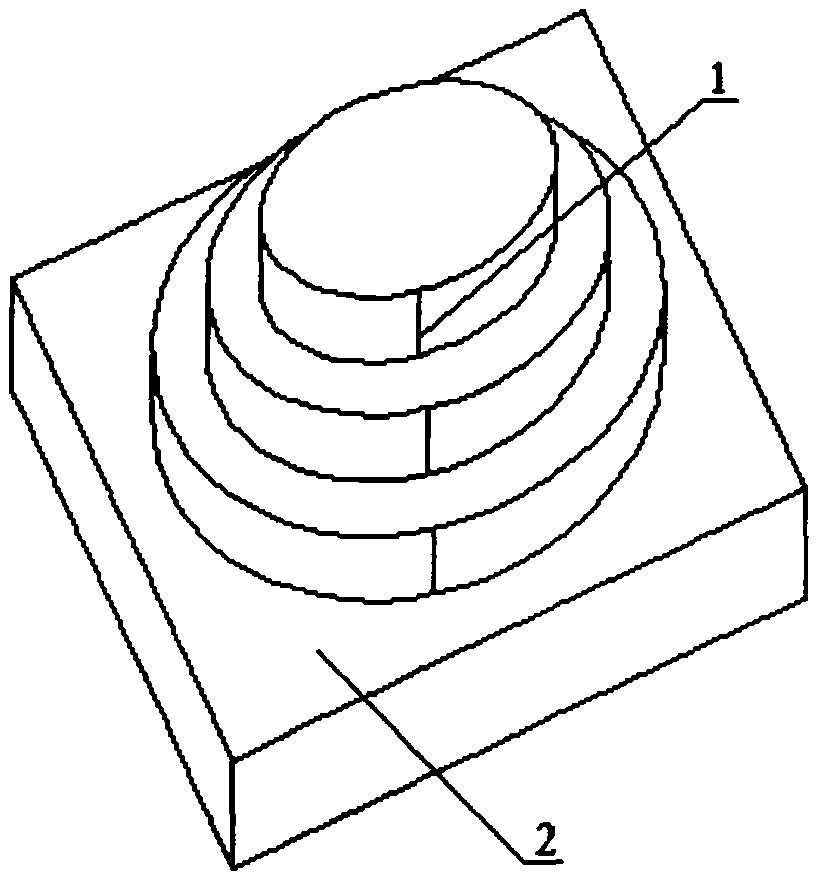

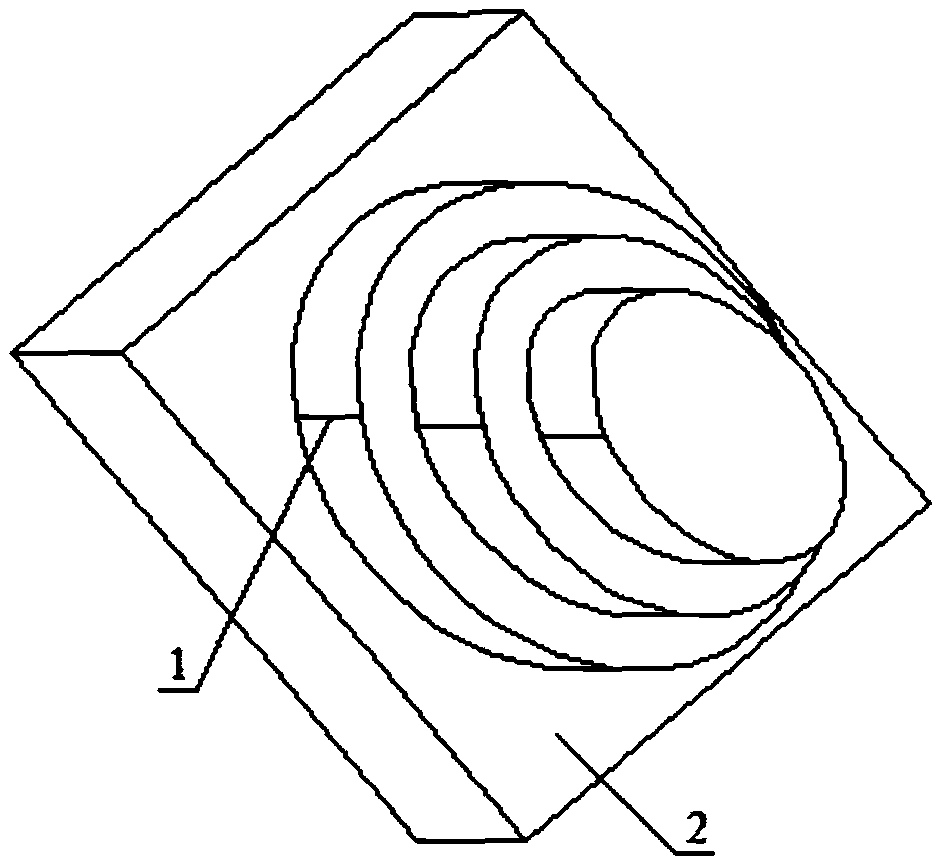

[0037] Embodiment 1: with image 3 Taking the cylindrical workpiece 2 with a diameter of φ100mm processed by the parallel machine tool 3 as an example, the hinge of the wheel pattern 1 produced by the parallel machine tool 3 is judged.

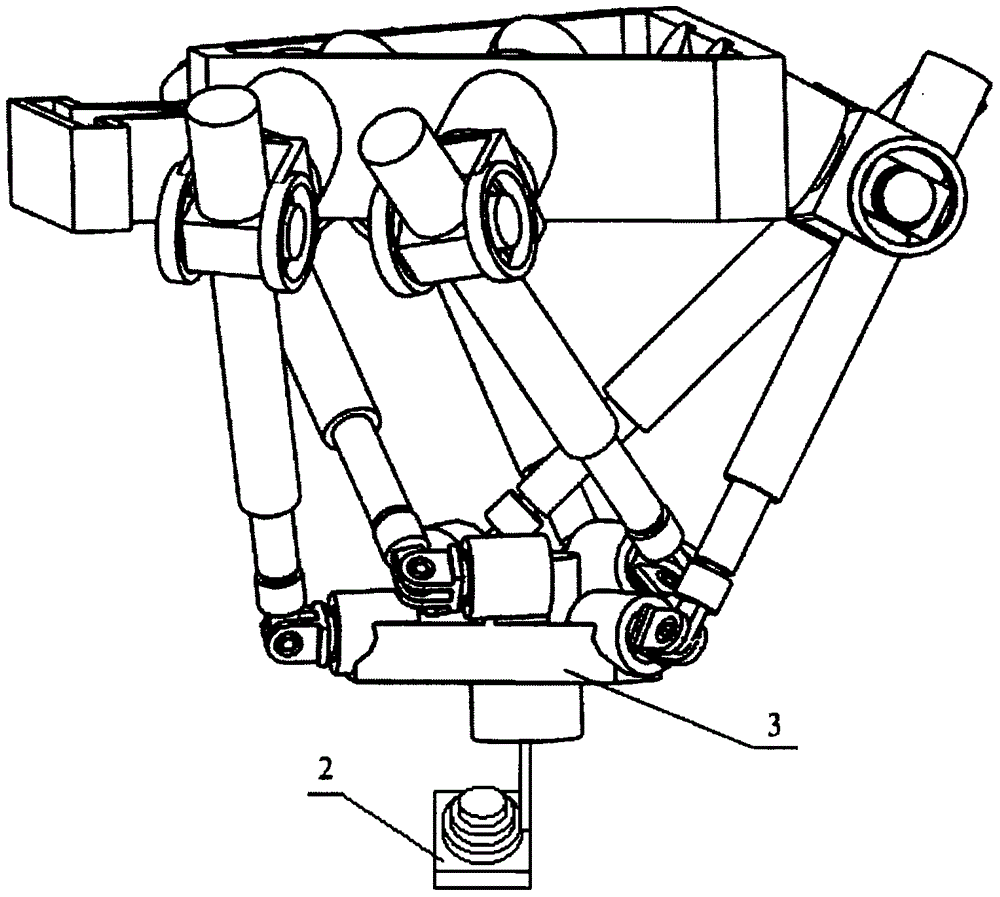

[0038] Parallel machines such as Figure 4 As shown, the structure diagram of the parallel machine tool is as follows Figure 5 As shown, the fixed platform 7 and the spline sleeve 8 pass through the universal joint B i connection, the moving platform 14 and the spline shaft 9 pass through the universal joint b i Connection, the spline sleeve 8 and the spline shaft 9 are spline connection, one end of the spline shaft 9 is connected with the servo motor 4, the electric spindle 13 is installed at the center of the moving platform 14, and the tool 12 is installed at the lower end of the electric spindle 13; The key sleeve 8 and the spline shaft 9 form a connecting rod, and the universal hinge B i with universal hinge b i The spline sleeve 8 ...

Embodiment 2

[0048] Embodiment 2: with image 3 Taking the cylindrical workpiece 2 with a diameter of φ80mm processed by the parallel machine tool 3 as an example, the hinge of the wheel pattern 1 generated by the parallel machine tool 3 is judged.

[0049] The step of judging the hinge that the parallel machine tool 3 produces the wheel pattern 1 is the same as that in embodiment 1, measured with a coordinate measuring machine 15 Figure 1~2 The two wheel patterns 1 on the surface of the cylindrical workpiece 2 with a diameter of φ80mm shown are respectively at the corners of 18.6° and 36.6° at the center of the moving platform 14 around the axis of the workpiece 2, calculated according to the structure of the parallel machine tool 3 and the movement of the connecting rod See Table 2 for the rotation angle of the center of the moving platform 14 around the axis of the workpiece 2 when the connecting rod reverses around the moving and fixed axes of the universal joint, and the connecting ro...

Embodiment 3

[0052] Embodiment 3: with image 3 Taking the cylindrical workpiece 2 with a diameter of φ60mm processed by the parallel machine tool 3 as an example, the hinge of the wheel pattern 1 generated by the parallel machine tool 3 is judged.

[0053] The step of discriminating the hinge that the parallel machine tool produces the wheel pattern is the same as that in embodiment 1, measured with a coordinate measuring machine 15 Figure 1~2 The two wheel patterns 1 on the surface of the cylindrical workpiece 2 with a diameter of φ60 mm shown are respectively at the corners of 19.1° and 36.3° at the center of the moving platform 14 around the axis of the workpiece 2, calculated according to the structure of the parallel machine tool 3 and the movement of the connecting rod Connecting rod B 3 b 3 Universal hinge b on the revolving platform 14 3 When the moving shaft of the moving platform is reversed relative to the moving platform 14, the rotation angles of the center of the moving p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com